This page, just like the Dart itself, is under construction.

(1/30/01)

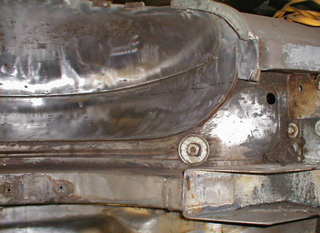

This is the size that the wheelwell started out as. The plan was to section the inner wheelhouse and bring it straight in (or down as the case may be).

There was a little rust through where the rear wheelhouse sections and trunk extensions came together. If you look closely, you can see the cut line drawn on the metal. I started cutting on the rear section just inside of the stock flange. I used a plasma cutter for all of the cuts and from start to finish was under half an hour. Most of that was spent being amazed at how easy it was going. One thing that has to be done is to drill the spotwelds out on the trunk brace and package tray support.

As you can see in the right picture, I wasn't able to follow the stock flange all the way. The braces for the window area and interior sheetmetal get in the way of following the stock flange. However, the stock flange curves and shouldn't be followed anyway for a straight cut.

The seat belt mounts will also have to be removed. I plan on reinstalling them so I used an air chisel with a flat blade. Came off fairly easy.

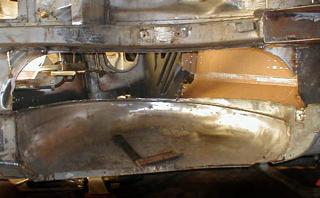

All done! Pretty easy actually. I added a piece of 18 ga. sheet that measured 2.25" at the front and rear ends and about 1 7/8" in the middle as well as about 52" long. I ground down the frame rail another 1/4" or so and then tacked the wheelhouse to it in order to figure out where the original radiused pieces of the trunk pan would fit. Once they were sandblasted and cut to fit they were tacked in place. The long 2.25x52" piece was then added starting at the rear of the well and stitched along the top and bottom until I reached the front of the wheelwell.

This is what the stock trunk mount looked like before the mini-tub. I drilled the spotwelds out that connected the two trunk brace pieces together. This allowed the wheelwell piece to be removed with the inner well, and then removed and repositioned after the tubbing.

This is how the brace and the mini-tub look from the inside. A little grinding and some filler and nobody will know the difference!

This is of the drivers side with the inner well cut out. You can see the original radius sections blasted, fitted, and tacked back into position.

I did the drivers side a little differently and tacked the filler to the inner well out of the car. I was able to get a tighter fit for the most part. I would suggest doing it this way, especially if your doing the tub with the car on the ground like normal.

This is the side by side comparison of before and after. Definately worth the time. Now all that is left is to backspace the wheels properly.