Click on the image for a larger picture

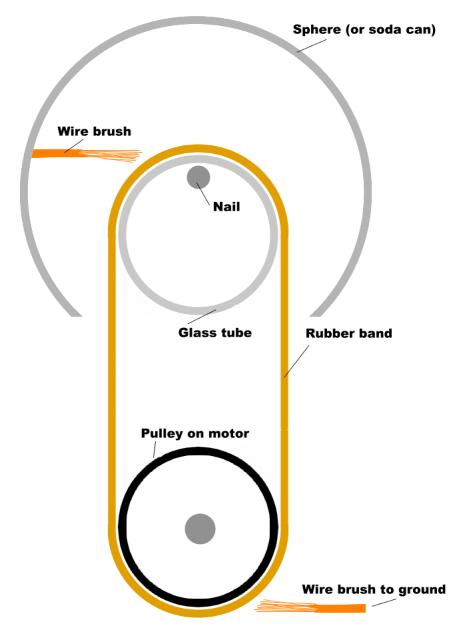

The first thing to do is to cut a 2 to 3 inch long piece of

3/4 inch PVC pipe, and glue that to the wooden base. This

piece will hold the generator up, and allow us to remove it

to more easily replace the rubber band, or make adjustments.

The PVC "T" connector will hold the small motor. The motor fits

too loosely by itself, so we wrap paper or tape around it

to make a snug fit. The shaft of the motor can be left bare,

but the generator will work a little better if it is made fatter

by wrapping tape around it, or (better) putting a plastic rod

with a hole in the center onto the shaft to act as a pulley for

the rubber band.

Next, we drill a small hole in the side of the PVC "T" connector,

just under the makeshift pulley on the motor. This hole will

be used to hold the lower "brush", which is simply a bit of

stranded wire frayed at the end, that is almost

touching the rubber band on the pulley.

As the photo shows, the stranded wire is held in place with some

electrical tape, or some other tape or glue.

The rubber band is now placed on the pulley, and allowed to hang

out the top of the "T" connector.

Click on the image for a larger picture

The first thing to do is to cut a 2 to 3 inch long piece of

3/4 inch PVC pipe, and glue that to the wooden base. This

piece will hold the generator up, and allow us to remove it

to more easily replace the rubber band, or make adjustments.

The PVC "T" connector will hold the small motor. The motor fits

too loosely by itself, so we wrap paper or tape around it

to make a snug fit. The shaft of the motor can be left bare,

but the generator will work a little better if it is made fatter

by wrapping tape around it, or (better) putting a plastic rod

with a hole in the center onto the shaft to act as a pulley for

the rubber band.

Next, we drill a small hole in the side of the PVC "T" connector,

just under the makeshift pulley on the motor. This hole will

be used to hold the lower "brush", which is simply a bit of

stranded wire frayed at the end, that is almost

touching the rubber band on the pulley.

As the photo shows, the stranded wire is held in place with some

electrical tape, or some other tape or glue.

The rubber band is now placed on the pulley, and allowed to hang

out the top of the "T" connector.

Click on the image for a larger picture

Next, cut another 3 or 4 inch piece of 3/4 inch PVC plumbing pipe.

This will go into the top of the "T" connector, with the rubber band

going up through it. Use the small nail to hold the rubber band

in place, as in the photo below. The length of the PVC pipe should

be just enough to fit the rubber band. The rubber band should not

be stretched too tightly, since the resulting friction would prevent

the motor from turning properly, and increase wear on the parts.

Click on the image for a larger picture

Next, cut another 3 or 4 inch piece of 3/4 inch PVC plumbing pipe.

This will go into the top of the "T" connector, with the rubber band

going up through it. Use the small nail to hold the rubber band

in place, as in the photo below. The length of the PVC pipe should

be just enough to fit the rubber band. The rubber band should not

be stretched too tightly, since the resulting friction would prevent

the motor from turning properly, and increase wear on the parts.

Click on the image for a larger picture

Cut the styrofoam cup about an inch from the bottom, and carefully

cut a 3/4 inch diameter hole in the center of the bottom of the cup.

This hole should fit snugly onto the 3/4 inch PVC pipe.

Click on the image for a larger picture

Cut the styrofoam cup about an inch from the bottom, and carefully

cut a 3/4 inch diameter hole in the center of the bottom of the cup.

This hole should fit snugly onto the 3/4 inch PVC pipe.

Click on the image for a larger picture

Now drill three holes near the top of the PVC union coupling.

Two of these holes need to be diametrically opposite one another,

since they will hold the small nail which will act as an axle

for the rubber band. The third hole is between the other two,

and it will hold the top "brush", which, like the bottom brush,

will almost touch the rubber band.

The top brush is taped to the PVC union coupler, and the coupler

is placed on the 3/4 inch pipe, above the styrofoam cup collar.

The rubber band is threaded through the coupler, and held in

place with the small nail, as before.

Bare the top brush (so it has no insulation) and twist it to

keep the individual wires from coming apart. You can solder the

free end if you like, but it is not necessary.

The free end of the top brush will be curled up inside the empty

soda can when we are done, and thus electrically connect the soda

can to the top brush.

Click on the image for a larger picture

Now drill three holes near the top of the PVC union coupling.

Two of these holes need to be diametrically opposite one another,

since they will hold the small nail which will act as an axle

for the rubber band. The third hole is between the other two,

and it will hold the top "brush", which, like the bottom brush,

will almost touch the rubber band.

The top brush is taped to the PVC union coupler, and the coupler

is placed on the 3/4 inch pipe, above the styrofoam cup collar.

The rubber band is threaded through the coupler, and held in

place with the small nail, as before.

Bare the top brush (so it has no insulation) and twist it to

keep the individual wires from coming apart. You can solder the

free end if you like, but it is not necessary.

The free end of the top brush will be curled up inside the empty

soda can when we are done, and thus electrically connect the soda

can to the top brush.

Click on the image for a larger picture

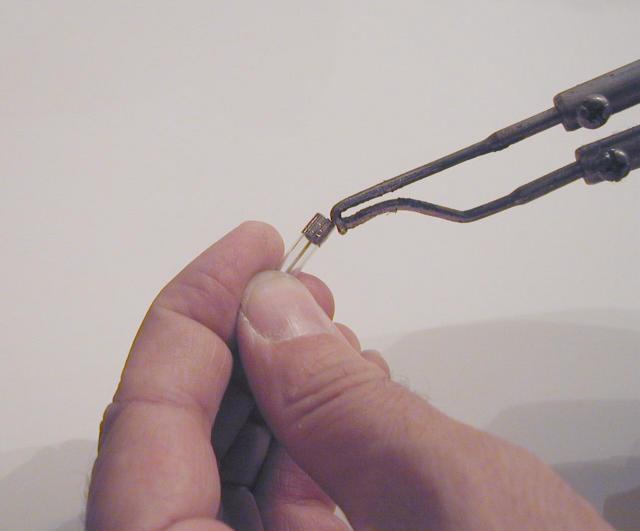

We need a small glass tube to act as both a low-friction top pulley,

and as a "triboelectric" complement to the rubber band, to generate

static electricity by rubbing. Glass is one of the best materials

to rub against rubber to create electricity.

We get the tube by taking apart a small electrical fuse. The metal

ends of the fuse come off easily if heated with a soldering iron or

a match. The solder inside them drips out when they come off, so

be careful. The glass, the metal cap, and the molten solder are

all quite hot, and will blister the skin if you touch them before

they cool.

Click on the image for a larger picture

We need a small glass tube to act as both a low-friction top pulley,

and as a "triboelectric" complement to the rubber band, to generate

static electricity by rubbing. Glass is one of the best materials

to rub against rubber to create electricity.

We get the tube by taking apart a small electrical fuse. The metal

ends of the fuse come off easily if heated with a soldering iron or

a match. The solder inside them drips out when they come off, so

be careful. The glass, the metal cap, and the molten solder are

all quite hot, and will blister the skin if you touch them before

they cool.

Click on the image for a larger picture

The resulting glass tube has nice straight, even edges, which are

"fire polished" for you, so there is no sharp glass, and no uneven

edges to catch on the PVC and break the glass.

The next step is a little tricky. The small nail is placed through

one of the two holes in the PVC union coupler, and the small glass tube

is placed on the nail. Then the rubber band is placed on the

glass tube, and the nail is then placed in the second hole. The rubber

band is on the glass tube, which is free to rotate around the nail.

Click on the image for a larger picture

The resulting glass tube has nice straight, even edges, which are

"fire polished" for you, so there is no sharp glass, and no uneven

edges to catch on the PVC and break the glass.

The next step is a little tricky. The small nail is placed through

one of the two holes in the PVC union coupler, and the small glass tube

is placed on the nail. Then the rubber band is placed on the

glass tube, and the nail is then placed in the second hole. The rubber

band is on the glass tube, which is free to rotate around the nail.

Click on the image for a larger picture

Now we glue the styrofoam collar in place on the PVC pipe.

I like to use a hot glue gun for this, since the glue can be

laid on thickly to stabilize the collar, and it sets quickly

and does not dissolve the styrofoam.

Click on the image for a larger picture

Now we glue the styrofoam collar in place on the PVC pipe.

I like to use a hot glue gun for this, since the glue can be

laid on thickly to stabilize the collar, and it sets quickly

and does not dissolve the styrofoam.

Click on the image for a larger picture

At this point we are ready for the empty soda can.

Aluminum pop-top cans are good for high voltage because

they have nice rounded edges, which minimizes "corona discharge".

With a sharp knife, carefully cut out the top of the soda can.

Leave the nice crimped edge, and cut close to the side of the

can so as to leave very little in the way of sharp edges. You

can smooth the cut edge by "stirring" the can with a metal tool

like a screwdriver, pressing outward as you stir, to flatten the

sharp edge.

Tuck the free end of the top brush wire into the can, and invert

the can over the top of the device, until it rests snugly on the

styrofoam collar.

Click on the image for a larger picture

At this point we are ready for the empty soda can.

Aluminum pop-top cans are good for high voltage because

they have nice rounded edges, which minimizes "corona discharge".

With a sharp knife, carefully cut out the top of the soda can.

Leave the nice crimped edge, and cut close to the side of the

can so as to leave very little in the way of sharp edges. You

can smooth the cut edge by "stirring" the can with a metal tool

like a screwdriver, pressing outward as you stir, to flatten the

sharp edge.

Tuck the free end of the top brush wire into the can, and invert

the can over the top of the device, until it rests snugly on the

styrofoam collar.

Click on the image for a larger picture

The last step is to attach the batteries. I like to solder a

battery clip to the motor terminals, and then clip this onto

either a nine-volt battery, or a battery holder for two AA

size batteries. The nine-volt battery works, but it runs the

motor too fast, making a lot of noise, and risking breakage of

the glass tube. It does, however, make a slightly higher voltage,

until the device breaks.

Click on the image for a larger picture

The last step is to attach the batteries. I like to solder a

battery clip to the motor terminals, and then clip this onto

either a nine-volt battery, or a battery holder for two AA

size batteries. The nine-volt battery works, but it runs the

motor too fast, making a lot of noise, and risking breakage of

the glass tube. It does, however, make a slightly higher voltage,

until the device breaks.

Click on the image for a larger picture

To use the Van de Graaff generator, simply clip the battery to the

battery clip. If the brushes are very close to the ends of the rubber

band, but not touching, you should be able to feel a spark from the

soda can if you bring your finger close enough. It helps to hold onto

the free end of the bottom brush with the other hand while doing this.

Click on the image for a larger picture

To use the Van de Graaff generator, simply clip the battery to the

battery clip. If the brushes are very close to the ends of the rubber

band, but not touching, you should be able to feel a spark from the

soda can if you bring your finger close enough. It helps to hold onto

the free end of the bottom brush with the other hand while doing this.

Click on the image for a larger picture

To use our generator to power the Franklin's Bells we built in the

previous section

of the book, clip the bottom brush wire to one "bell", and attach a

wire to the top of the generator, connecting it to the other "bell".

The pop-top clapper of the Franklin's Bells should start jumping between

the soda cans. It may need a little push to get started.

Click on the image for a larger picture

To use our generator to power the Franklin's Bells we built in the

previous section

of the book, clip the bottom brush wire to one "bell", and attach a

wire to the top of the generator, connecting it to the other "bell".

The pop-top clapper of the Franklin's Bells should start jumping between

the soda cans. It may need a little push to get started.

Click on the image for a larger picture

Click on the image for a larger picture

Most negative

(items at this end steal electrons)

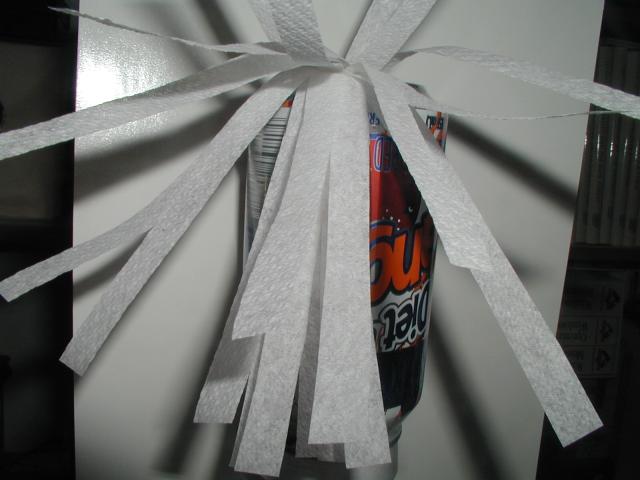

We take a paper napkin, and cut thin strips of the lightweight paper.

We then tape the ends of the paper together at one end, and tape that

end onto the Van de Graaf generator.

The effect will look somewhat like long hair cascading down the soda can.

Now turn the Van de Graaff generator on. The thin strips of paper all

get the same charge, and start to repel from one another. The effect

is "hair raising". The strips start to stand out straight from the

can, like the hair on the back of a scared cat.

We take a paper napkin, and cut thin strips of the lightweight paper.

We then tape the ends of the paper together at one end, and tape that

end onto the Van de Graaf generator.

The effect will look somewhat like long hair cascading down the soda can.

Now turn the Van de Graaff generator on. The thin strips of paper all

get the same charge, and start to repel from one another. The effect

is "hair raising". The strips start to stand out straight from the

can, like the hair on the back of a scared cat.

Click on the image for a larger picture

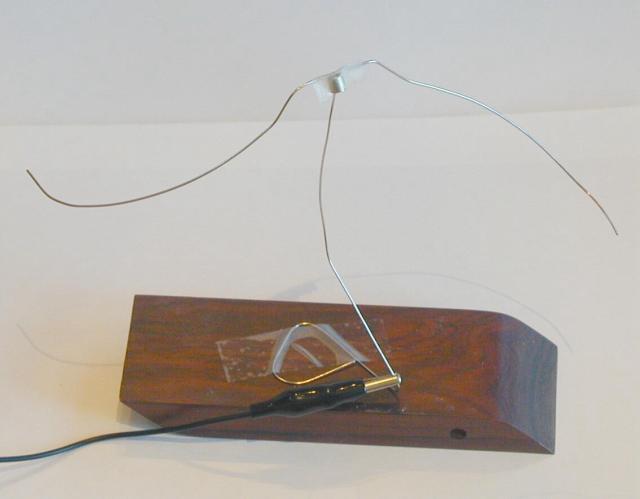

First, take one piece of wire (a straightened paper clip will do),

and cut the end at an angle so it is sharp.

Bend the other end into a rough loop or triangle, so the wire will

stand up with the sharp point facing straight up. A little tape

will help hold it onto the table, or a block of wood.

Click on the image for a larger picture

First, take one piece of wire (a straightened paper clip will do),

and cut the end at an angle so it is sharp.

Bend the other end into a rough loop or triangle, so the wire will

stand up with the sharp point facing straight up. A little tape

will help hold it onto the table, or a block of wood.

Click on the image for a larger picture

The armature (the part that spins) is made from the other piece of wire

and the metal cap we saved when we took apart the fuse.

Sharpen both ends of the wire by cutting the ends at a diagonal, like we

did with the base wire.

Bend the wire into an S shape.

The pointed ends of the wire should point at 90 degrees from the center

straight part of the wire.

Click on the image for a larger picture

The armature (the part that spins) is made from the other piece of wire

and the metal cap we saved when we took apart the fuse.

Sharpen both ends of the wire by cutting the ends at a diagonal, like we

did with the base wire.

Bend the wire into an S shape.

The pointed ends of the wire should point at 90 degrees from the center

straight part of the wire.

Click on the image for a larger picture

Attach the metal cap to the center of the wire with tape.

Place the cap onto the pointed end of the base wire, and bend the

S shaped ends of the armature wire down, so it will balance easily

on the sharp end of the base wire.

The armature should now spin freely if you tap it gently.

Connect a source of high voltage to the base wire using an alligator

clip or a wire. The high voltage source can be the Van de Graaff

generator, or just a couple square feet of aluminum foil pressed

against the front of your television set, as we did in earlier

projects.

As the high voltage is turned on, the armature will start to spin

in the direction away from the sharp points. The Van de Graaff

generator may need a good ground, or a person holding onto the

ground wire. The television will give the motor a good kick

every time it is turned on or off, and turning it on and off

every second will get it spinning quite rapidly.

Click on the image for a larger picture

Attach the metal cap to the center of the wire with tape.

Place the cap onto the pointed end of the base wire, and bend the

S shaped ends of the armature wire down, so it will balance easily

on the sharp end of the base wire.

The armature should now spin freely if you tap it gently.

Connect a source of high voltage to the base wire using an alligator

clip or a wire. The high voltage source can be the Van de Graaff

generator, or just a couple square feet of aluminum foil pressed

against the front of your television set, as we did in earlier

projects.

As the high voltage is turned on, the armature will start to spin

in the direction away from the sharp points. The Van de Graaff

generator may need a good ground, or a person holding onto the

ground wire. The television will give the motor a good kick

every time it is turned on or off, and turning it on and off

every second will get it spinning quite rapidly.