|

Intake Manifold

Updated 4 DEC 2001

(Flange info added)

|

So you've just spent $180 on mandrel

bent 6061 tubing, from which you plan to make an

intake manifold for your CorVAIRCRAFT engine.

Sure you are skilled enough to cut

and join the pieces together, but because you don't

have a TIG welder, you are going to have to bring

the pieces to someone who does.

The real problem is how to jig it accurately, in such a way that the person doing the

welding has access to the joint to tack the pieces

together. Well, I think I've come up with an

elegant solution. At least it worked very well for

me.

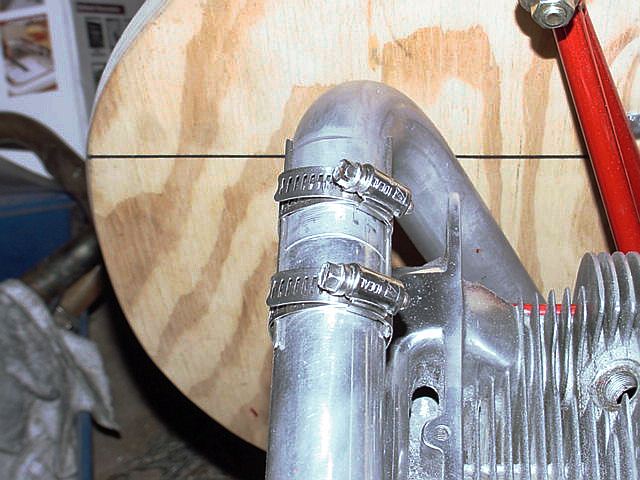

The materials you'll need are 2 hose

clamps per joint (I think it took 8 for my project) and 3

short pieced of welding rod per joint. |

All the work was done on the actual engine for which I

was building the runners.

|

|

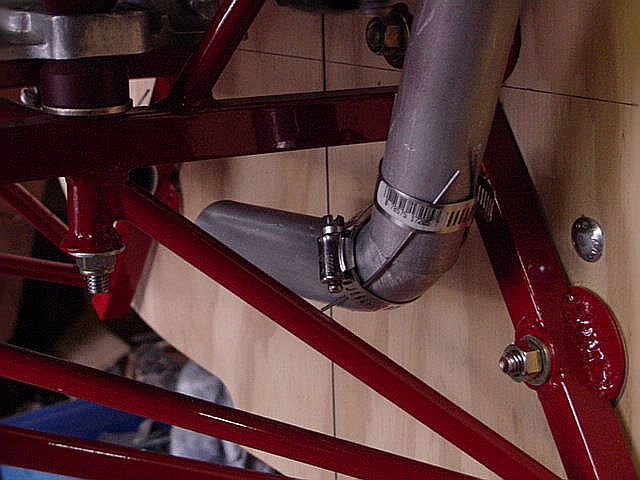

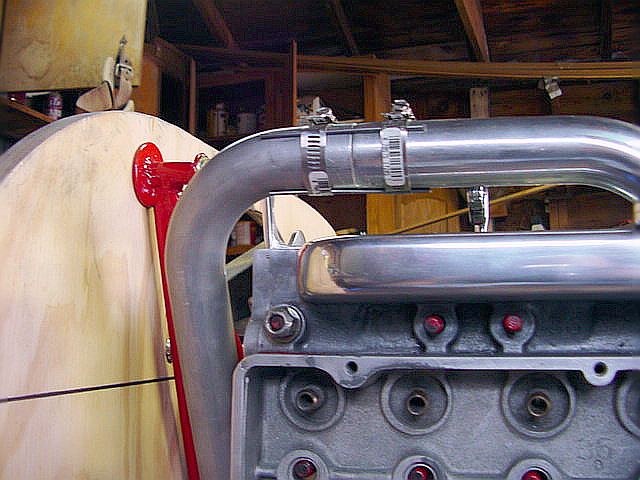

The intake manifold runners are made from mandrel bent

6061 aluminum

tubing, which I cut and had TIG welded for me by a local

sprint car

builder. The tubing is available from Burns Stainless

in Costa Mesa, CA

|

|

|

|

|

|

|

|

Notice in these

images, that the length of the horizontal runner (after

the bend) is not equal.

That's to compensate for the offset in the stock manifold

log's carburetor placement.

Due to these unequal length of these horizontal tubes, the completed intake runner system

is equal length, from the off centered

updraft Stromberg to each stock log.

|

|

|

|

|

|

|

But I digress...

By popular demand, I'm adding some info about milling

off the flange

and adding the new 1/4" plate flange I had TIG

welded in place.

It all started with making a plywood jig in which I could place the head,

and "mill" the cast flange (carb

base) off the top of the log.

I used a 3hp wood router with a 1/2" shank,

and with carbide blades to

make short work of the soft cast aluminum.

1/16" to 3/32" cuts are quite effortless.

I use WD-40 as a lubricant and coolant.

It keeps the aluminum chips from sticking to the carbide

too

|

|

|

Another view of the plywood jig.

|

|

Then with my angle grinder, belt sander Dremel with sanding drum,

orbital sander, and hand sanding, I got it to

this point. From here it was

polished on a buffer wheel, using 3 different grits

of rouge.

Although I don't have photos of the next step, I

fashioned 2 matched pairs

of flanges, one pair for each head. My son

is a VW enthusiast, so there

just happened to be a stock VW carb base gasket

kicking around on my work bench,

so I used it for a template to cut the flanges to it's

exact shape.

The round hole you see in the photo above is the stock

hole that goes

through the carb base I routered off. I don't

recall the ID of the gasket I

used for a template, but my welder asked that I

make the ID of the flange

just slightly larger than the opening, to produce s "step" for him

to weld the 2 pieces together. So the ID of the

flange is about 3/16" to

1/4" larger than the stock opening.

|

|

This shows the flange welded in place, with no

interior grinding. The weld

was belt sanded flush with the gasket mating

surface, but some of the weld

reduced the opening size.

Additionally, you can see that I've tapped this

1/4" piece of plate aluminum,

to receive the allen screws. These screws (with

1/4-20 threads) were tested in a

scrap piece of material, and tightened down

(with a 5" allen wrench) to a point

which almost exceeded my full strength, and

didn't strip. Don't know what

that works out to in ft-lbs, but it's stinkin'

high. I'm confident that they'll never strip

under normal circumstances, and when I'm

"done" with the engine, all allens will

be drilled, and safety wire will be installed.

|

|

Another view... note that all polishing was done

before welding.

The welding didn't hurt the polish work, and

doing it beforehand,

ensured a nice job right up to the joint.

This photo also shows the excess material removed from

between the log and

the head, between the intake ports.

|

|

Another close up. Right clicking on these

photos, and selecting

"view image", will enlarge the photo

another 25-30%.

|

Here's a shot after all extra material has been

removed from the opening.

|

....And another view.

I may fill over the top of the weld with some JB

Weld, and grind it all

nice and square, and do the same to the mating

part, so that there's no issues

with the transition from runner to log.

|

Bottom view, showing the Stromberg

updraft mounting flange.

Notice that it's offset to one side.

This was to make both runners the same length, as

mentioned above..

|

|

|