Rapid prototyping, also known as 3D printing, is a method of manufacturing where 3D substances are rapidly made on a reasonable size of machine linked to a computer having blueprints for the item. The fundamental principles are similar to 2D printer-materials cartridges, elasticity of output, and transformation of code to an evident pattern. 3D printing aficionados expect that house fabbers will guide in the custom industrialized revolution, and greatly lessen the necessity for centralized industrialization.

The equipment of 3d-printer came out in the middle of 1990's. After their introduction, futurists instantly predicted that the equipment would soon be found in every house. However, the cost of the components, which includes several flexible, mechanical tools, amounted 3D Printers to over twenty thousand dollars.

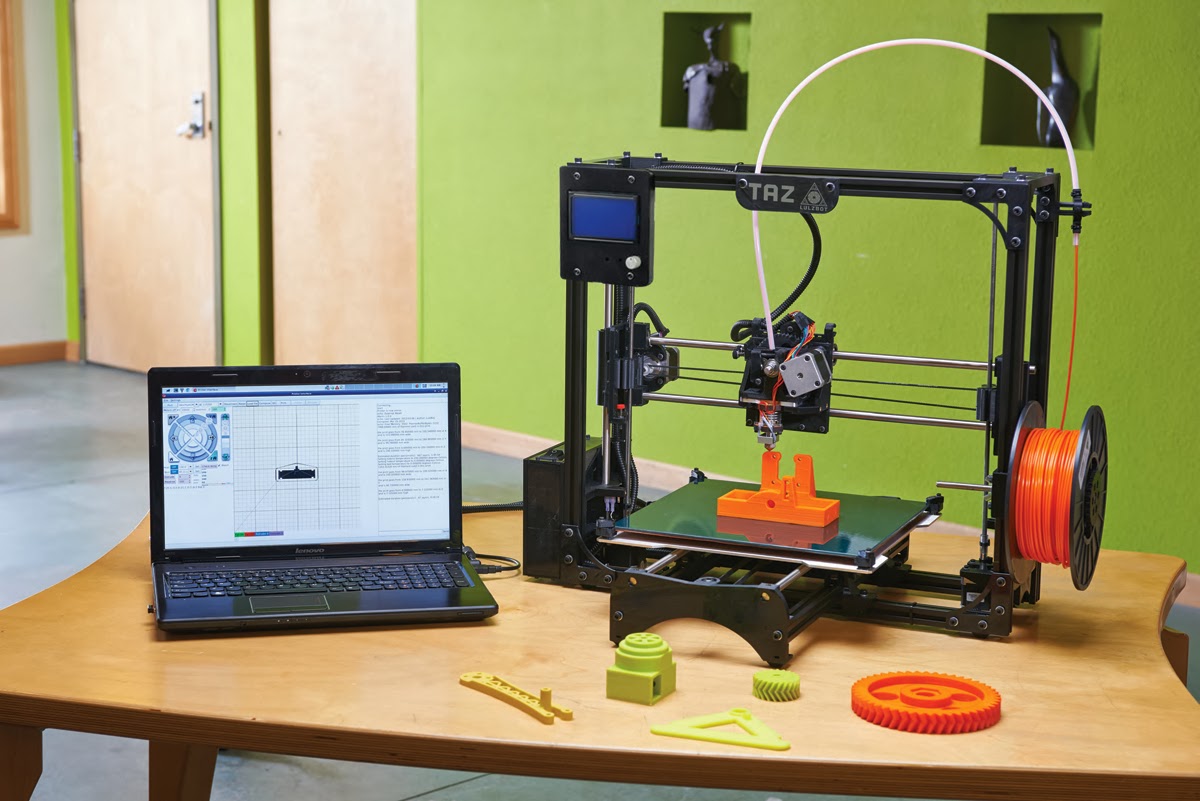

Recent 3D printer or copier is a fancy machine used by professional engineer or product designer, who uses it to create models to be used in the presentation to consumers, for instance. Nowadays, the present 3d-printer use various feed stocks like sawdust and adhesive, which may be pushed into the 3D substance in the duration that the design permits the layers to be incrementally applied.

The most recent 3D printing devices make use of metallic dust and a laser in making 3D substances from metal, which make the technology extra appealing. These devices have been used already by Israel and the U. S. in the manufacture of unmanned aerial vehicles or UAVs. The military of the United States is studying the battlefield-ready 3D printer which can be utilized to produce communication devices because they are needed.

Early protrusion of 3d-printer considered that they would likely use the combination of special polymers and lasers in the manufacture of products. There are particular polymers that solidify only in certain combination of light. This property may be demoralized by using a pair of lasers which separately fail to accomplish the optical conditions, however, in concurrence do perform them.

When a pair of lasers crosses into the solution, it hardens. By creating a structure starting from the soil up, a steady product may be produced when the solution polymer is sapped away. But this process of 3D printing had turned out, more costly and less precisely demanding method is utilized today.

Later, we could have 3D printers which will use nanotechnology that can make products through dropping them fragment by fragment. Preliminary work of the atomic tooltips will suggest the scientific feasibility and the simple machine will create the atomic scale like transistors, smaller wheels, and the "walking DNA". These things can be the pioneers to the more advanced and more developed manufacturing systems.