WHAT IS ELEMATIC HOLLOWCORE?

Elematic hollowcore is a precast, prestressed, concrete plank manufactured by a precision, extrusion process, from zero slump concrete providing outstanding dimensional control and uniformity. Slabs are cut to length to assure dimensional accuracy and smooth end finish.

Elematic hollowcore weighs less per square foot than similar decking units on the market. As a result, Elematic hollowcore offers a higher span-to-depth ratio.

The underside of Elematic hollowcore is steel form smooth, and can be either left as is or painted with a textured paint. In many floor applications, Elematic hollowcore may be used without concrete topping. Joints between slabs are grouted and feathered, suitable under-layment or padding applied, and finishing carpet, wood floor, or tile installed.

Elematic hollowcore is made under factory controlled conditions which permits extremely close and accurate tolerances, by licensed manufacturers throughout the United States and Canada.

Elematic hollowcore producers include many major manufacturers in the precast and prestressed concrete industry and are fully staffed to provide comprehensive sales and technical services.

APPLICATIONS

Elematic hollowcore has been used in almost every conceivable type of building and can be utilized with any wall bearing or framing system.

Elematic hollowcore PROPERTIES AND LOAD CAPACITY

Elematic hollowcore is manufactured in 4’-0” widths and various depths.

FIRE RATING

Elematic hollowcore meets the requirements for the restrained and unrestrained fire ratings of ASTM E119 and is listed by Underwriters Laboratories, Inc. for two hour fire resistant classifications (untopped), restrained and unrestrained conditions. Three and four hour ratings are also available with field-cast toppings.

ACOUSTICAL PROPERTIES

Elematic hollowcore concrete floor slabs are resistant to air-borne noise and transmission of impact noise and provide qualities superior to those of a solid concrete slab of equivalent thickness.

Acoustical tests show ratings of STC 48 and NRC 55 for untopped floors. In Canada Elematic hollowcore is approved by the C.M.H.C. approval No.: 7098.

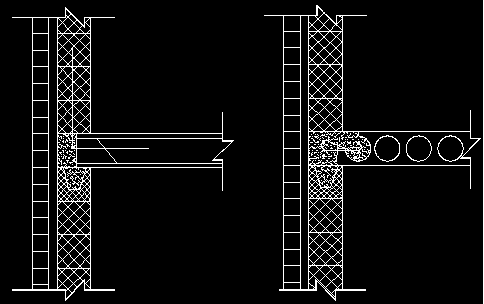

USE OF VOIDS

Voids may be used for electrical raceways and for forced air supply and return ducts.

ECONOMY

The use of Elematic hollowcore structural floor and roof slabs will result in a lower total construction cost for your next project. The time and weather delays of on-site forming and curing of poured concrete are eliminated.

Elematic hollowcore floor and roof slabs are delivered directly to the job site to be erected immediately – even in inclement weather. The hollow cells are space and cost savers as they can be used for heating and air-conditioning ducts, exhausts to the outside, electrical wiring and piping.

MAINTENANCE

Because it is made of concrete, Elematic hollowcore requires very little or no maintenance. Elematic hollowcore gives the owner service for the entire life of the building.

PRETESTED

Elematic hollowcore is being used in structures throughout North America and has been thoroughly tested in field applications.

GENERAL

1. This trade shall manufacture, deliver and erect all precast – prestressed Elematic hollowcore units, including grouting between units.

2. The Manufacturer shall submit erection drawings for Architect’s approval.

3. All precast hollowcore units shall be Elematic hollowcore, machine extruded in a closely controlled manufacturing process.

4. Elematic hollowcore units shall be manufactured in accordance with the latest edition of ACI 318 or CSA A23.3.

MATERIAL AND MANUFACTURE

1. All materials used in the manufacture of Elematic hollowcore units shall conform to all pertinent ACI and CSA specifications.

2. Concrete shall have a minimum compressive strength of 4,000 psi at transfer and 6,000 psi at 28 days.

3. The prestress strand shall be uncoated 7-wire strand conforming to CSA A135 or ASTM A416.

4. The Elematic hollowcore unit shall be manufactured by an extrusion process using smooth rigid steel forms and cut to length as shown on the shop drawings.

ERECTION

1. Erection shall be carried out by experienced precast erectors under competent supervision.

2. Bearing surfaces for the Elematic hollowcore slabs will be prepared by others to a true level surface.

3. Construction of the building within the acceptable tolerances shall be the responsibilities of the general contractor.

4. Slabs shall be carefully grouted using a 1:3 cement-sand grout mix and care shall be taken to ensure that the joints between the slabs are properly filled.

Section Properties |

|---|

Imperial |

| Self Weight ................................. 50 psf |

| Cross Section Area ................... 214 in2 |

| Moment of Inertia ................... 1660 in4 |

| Yb ............................................. 4.1 in |

| Yt .............................................. 3.9 in |

| Section Modulus (Sbot) ............. 405 in2 |

| Concrete Strength at: |

| Prestress (f'c1) ........................ 4000 psi |

| 28 days (f'c) ............................ 6000 psi |

| Number of Strand | Span - Feet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | |

| 3 | 528 | 393 | 276 | 200 | 148 | 111 | 84 | 63 | 46 | |||||

| 4 | 545 | 441 | 368 | 274 | 207 | 159 | 123 | 96 | 74 | 58 | 44 | |||

| 5 | 563 | 445 | 380 | 324 | 263 | 204 | 160 | 127 | 101 | 81 | 64 | 51 | 39 | |

| 6 | 581 | 470 | 392 | 335 | 291 | 246 | 195 | 157 | 126 | 103 | 83 | 67 | 54 | 42 |

| 7 | 598 | 484 | 404 | 345 | 300 | 264 | 226 | 185 | 150 | 123 | 101 | 83 | 68 | 55 |

Section Properties |

|---|

Imperial |

| Self Weight ................................. 75 psf |

| Cross Section Area ................... 288 in2 |

| Moment of Inertia .................... 3014 in4 |

| Yb ........................................... 5.37 in |

| Yt ............................................ 4.63 in |

| Section Modulus (Sbot) ............. 561 in2 |

| Concrete Strength at: |

| Prestress (f'c1) ........................ 4000 psi |

| 28 days (f'c) ............................ 6000 psi |

| Number of Strand | Span - Feet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | |

| 3 | 651 | 507 | 355 | 256 | 188 | 139 | 103 | 76 | 51 | |||||

| 4 | 665 | 536 | 446 | 351 | 263 | 200 | 154 | 118 | 84 | 57 | ||||

| 5 | 679 | 548 | 456 | 388 | 334 | 258 | 202 | 158 | 118 | 86/td> | 60 | 39 | ||

| 6 | 693 | 559 | 465 | 396 | 343 | 301 | 246 | 196 | 151 | 114 | 85 | 61 | 41 | |

| 7 | 707 | 571 | 475 | 405 | 351 | 308 | 273 | 232 | 185 | 143 | 110 | 83/td> | 60 | 42 |