The upper part is advertisement form the sponsors and has no relation to the author of the following homepage.

Development of Advanced Thermoelectric Materials

Modern materials processing is related to nano-dimensions. On atomic scale several new physical phenomena are occuring.

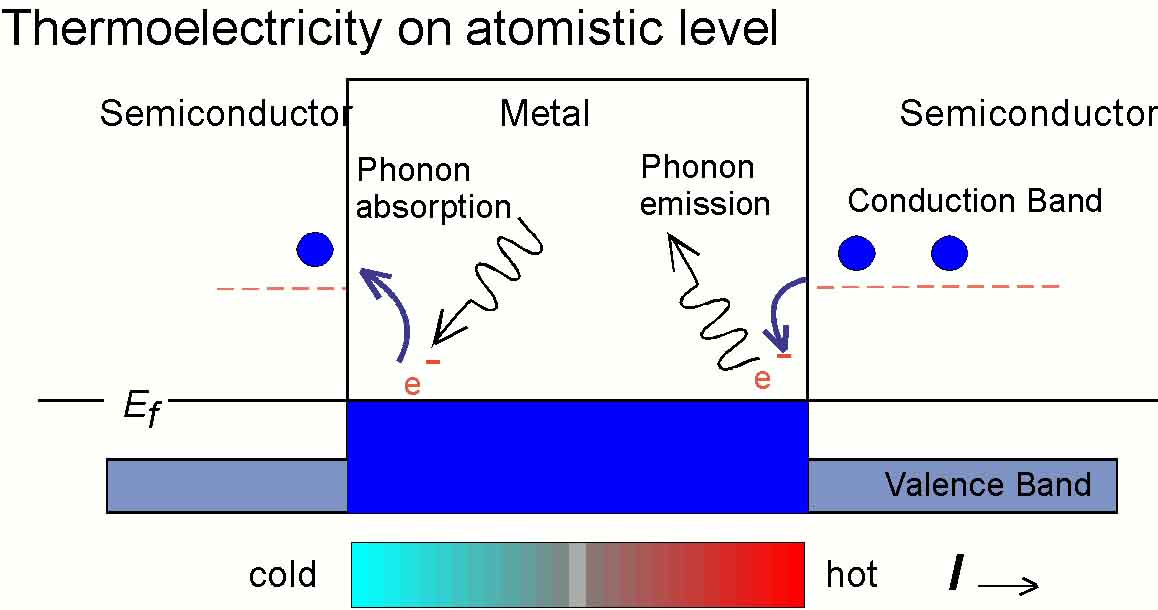

Thermoelectric materials are the key materials for the energy supply in future. Waste heat can be converted into usefull electric energy. The Seebeck and Peltier effects are known for a long time, but since the discovery of the oxide ceramic NaCo2O4, a material with an extreme high Seebeck coefficient, the efficiency of these devices is expected to increase very much. For physicists a lot of new research need to be done, since this effect is not yet completely understood on atomistic scale. A large effective electron mass is one of the key parameters for a large Seebeck coefficient and it can be deduced from electronic bandstructure calculations. Present studies are focussed on Perovskite and Half-Heusler crystal structure in order to find out guiding principles for new advanced thermoelectric materials. Furthermore, nano-structured materials will have an even higher Seebeck coefficient due to the confinement of the 2-dimensional electron gas (2DEG).

New Materials create new Energy sources.

Mankind has only about ten or twenty years left to solve the CO2 and greenhouse problem, otherwise a point-of-no-return will be reached. Present energy support is not sustainable. Hence, we need new technologies to maintain present living standard and any new technology is related to new materials. Especially thermoelectric materials can help to reduce the 30% loss at the energy conversion from primary energy resources and the 30% loss at the conversion from the energy carrier into used energy. Any waste heat can be converted into electricity ans in such a way a lot of otherwise disspated energy can be recycled or reused in an environmental friendly way. Thermoelectric energy generators (TEG) need no moving parts or maintance. Also, thermoelectric materials used as Peltier coolers save a lot of energy when cooling is required. An increase in conversion efficiency is expected in near future. As a vision, replacement of air-conditioner by thermoelectric wall papers or thermoelectric jackets for field workers may be available soon.

Other research projects considered in the past:

1) The understanding of the bonding of organic macromolecules on ceramic substrates is useful for several applications, like gas-detectors, catalyst, or like in this example for developing solar cells with high perforemance. The composite between the organomettalic molecule PcM and the semiconductor ZnO can be processed in one process. Similar phenomena are also occuring at photocatalytic reactions, which are applied for depositing ceramic particles on substrates. This process leads to self-assembled monolayers in sub-micrometer dimension.

PcM on ZnO

2) Carbon-Nano-Tube (CNT) can be grown by a modified CVD process on Palladium substrates. A Pd nano-particles is remaining in the tip of the nanotube and acts as catalyst for further growth. This process can be used for producing nano-emitters with possible application as X-ray source. Other applications are nano-wires for electronic devices.

Pd Nanoparticle in Carbon-Nanotube

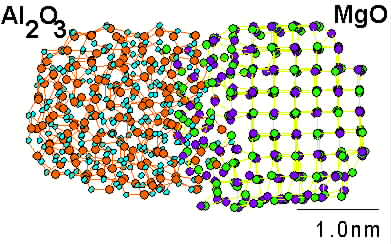

3) One of the most sucessfull processing method for nano-ceramics is the sol-gel process. In the slurry, complicated interactions between charged particles, polarized molecules and ions occur. Also, due to the relaxation of the atoms, the free energy is different, which means that the phase diagrams have to be revised. Further knowledge is necessary in order to improve the final ceramic.

Interaction between Alumina- and Magnesia-particles

4) The atomic structure of

Interfaces has strong influence on properties of composite

materials.

The Molecular Dynamic Method can principally predict most

properties of materials and, hence is an important tool for

development of advanced materials.

Intra-nano-composite material: Zirconia embedded in Magnesia

A few of the completed Research Projects

Al-Mg-Spinell-Formation during the sol-gel-process

Critical Thickness for Epitaxial Growth of BaTiO3-Thin Films on SrTiO3

Wurtzite Thin Films (GaN,ZnO,AlN) on Alumina surfaces

Fracture toughness of Alumina Single Crystals and Alumina-Zirconia-Nanocomposites

Critical Stress at Twins in Zirconia

Symmetrical Tilt Grain boundaries in Zinc Oxide

Mechanical Alloying of Ge-Si-Nanocrystals

Completed Research Projects concerning metals

Misfit Dislocations at TiAl/Ti3Al-Interfaces

Dislocations at Crack tips in NiAl/NbNiAl

HRTEM studies of nanocrystalline Palladium

Carbon-concentration at Ferrite/Perlite-Interfaces

Solid solution Hardening of Iron alloys

Coherent precipitates of Al-Li-alloys formed at room temperature

Hydrogen embrittlement in Al-Zn-Mg-alloys

Completed Research projects concerning the TEM-technique

Ice layer formation on EDS-Detectors

Preparation of intermetallic phases

<- back