I aligned the passenger side spring perch with the drivers side perch and welded it on using the same method mentioned before (because the differential housing is cast iron too).

Now that the housing is done, it was time to move on to the

knuckles. I chose to put the entire outer knuckles from the

Dana 30 onto the Dana 44 housing.I decided to used

the Dana 30 knuckles for a group of reasons;

(1) I don't have all the parts that I would need for the Scout

axles.

(2) Because of the shape of the Scout knuckles, I would lose

some turning radius if I tries to connect them to the Jeep

steering gearbox. The point at which the drag link connects to

the knuckle is a few inches further out from the center of the

wheel then the original Jeep set-up.

(3) The brakes are very similar in size, so there is no loss

or gain there.

(4) It's an easy thing to do.

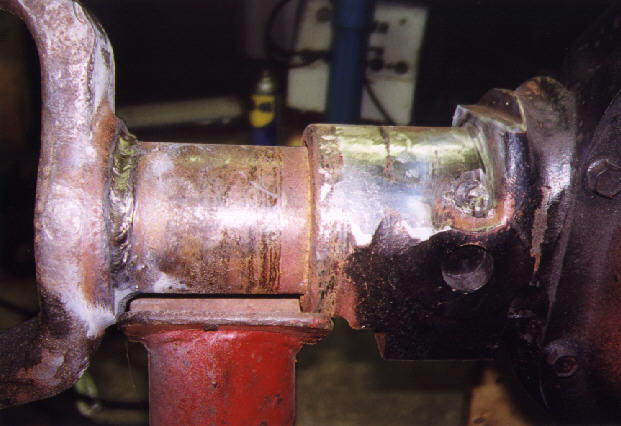

This is an easy bolt on-deal, that doesn't require any

modifications. I simply took apart the Dana 30 axle, had new

balljoints pressed in, and bolted them onto the Dana 44

yokes. I was able to reused all the knuckle parts from the

balljoints out, including the hubs (while retaining the Dana

44 axle shafts). Besides paint, the front axle is done.

On to Page 3

-or-

Back to the Home page