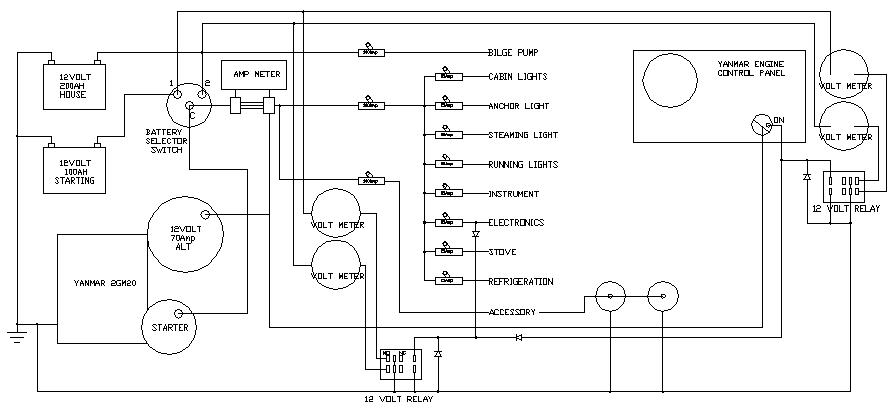

ELECTRICAL

PANEL UPGRADE

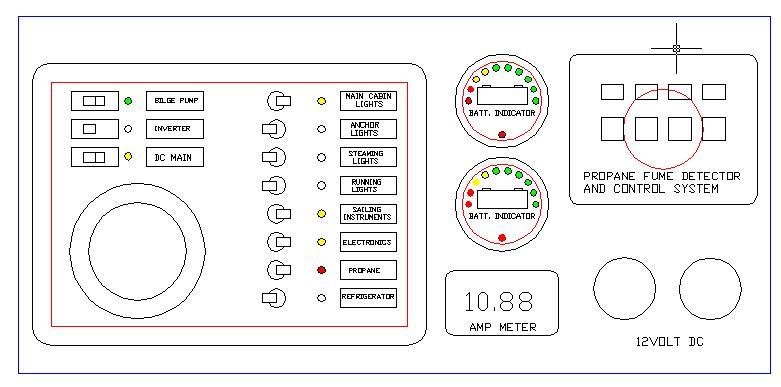

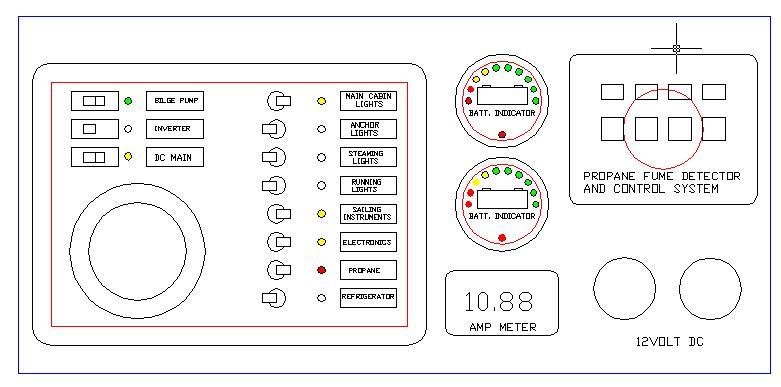

The CAL's

electrical panel was a prefabricated unit just for the CAL. After 20

yrs of use, the voltage

meter's accuracy has rendered it to just an indicator that the needle

moves.

The main battery switch is quite loose making it difficult to determine

which

battery is being used. I was able to add an additional breaker to it

when I

added the refrigeration system and keep it seperate and now I want to

add a

propane control system with leak detection.

I

could just drill through the board that

electrical panel was mounted on, but the engine control panel shares

the same

internal access area behind the steps. If I go too deep on both sides,

the

equipment will not fit. I decided to add additional features and build

it

outward towards the step. I still have a hard time drilling holes

and

decided to try to build the panel in a frame that I could add by

attaching with

just a few screws. That would allow it to utilize the large existing

panel hole

for routing all the wires through without having to cut extra holes for

inserting instruments, switches and additional wiring.

The battery

charge condition

was important to me, I wanted to be able to determine the battery

condition at

a glance. I thought it would be nice to have a couple outlets handy for

,, what

ever,,, and I definately needed to add the propane control system.

After

reading stories of finding dead batteries, I thought it would be nice

to add a

amperage display. If possible to display charging current to the

batteries and

still have it sensitive to display the lower usage currents for

the lights,

instruments, radio, etc....

The existing panel position

and wiring installation left little extra working loops of wire,

so I had

to design a new panel that was very similar to the old one. I

searched the

internet and found the Blueseas 8083 panel that was very similar in

size and

function. It had the battery selector switch, 8 breaker circuits and an

additional group of "C" class breakers, one as the master for the

other 8 breakers and 2 additional ones. Class "C" breakers are

not very popular, they are larger than the standard breakers and they

have

wider mounting locations, and rectangular through panel mount instead

of the

more popular round hole mount. I found a couple of the "C"

breakers and populated the panel. I wanted to have the bilge pump on a

separate

circuit and a spare possibly for an inverter.

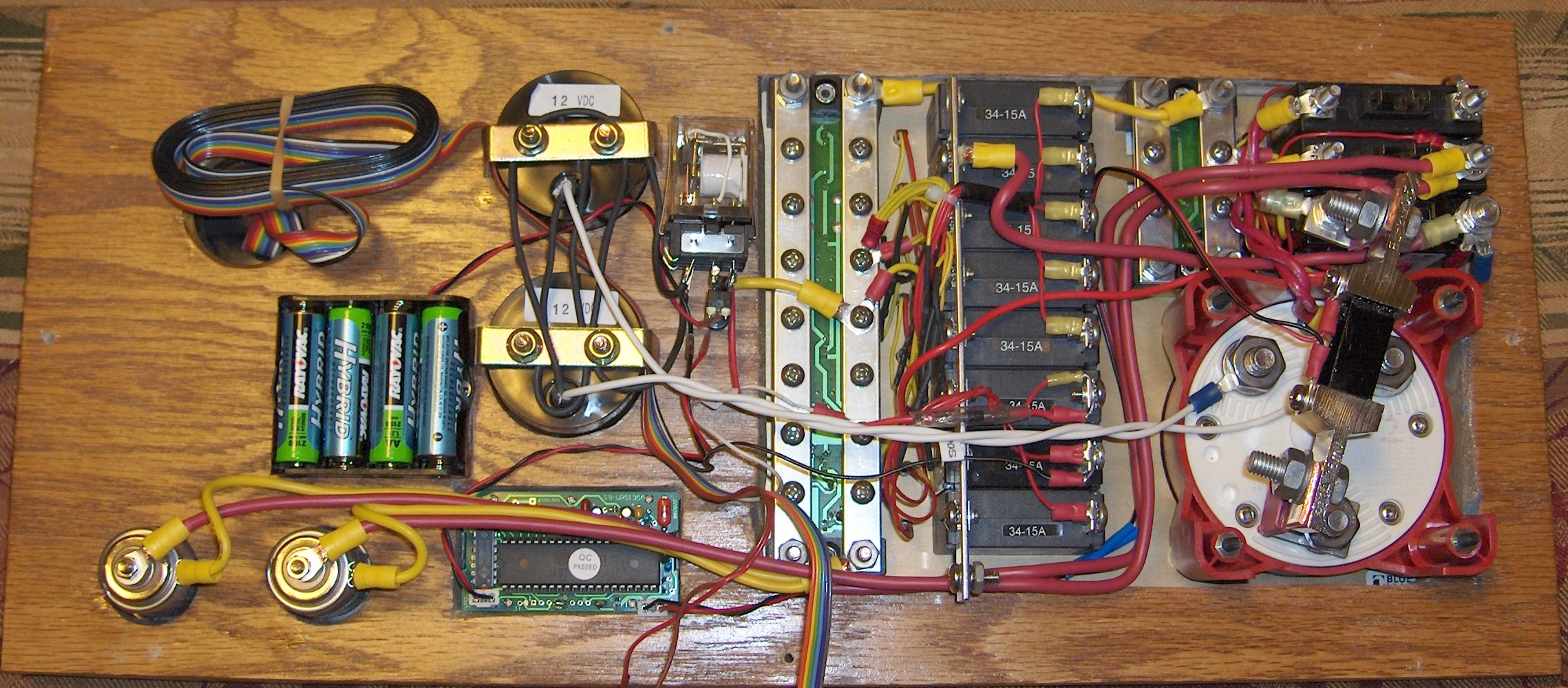

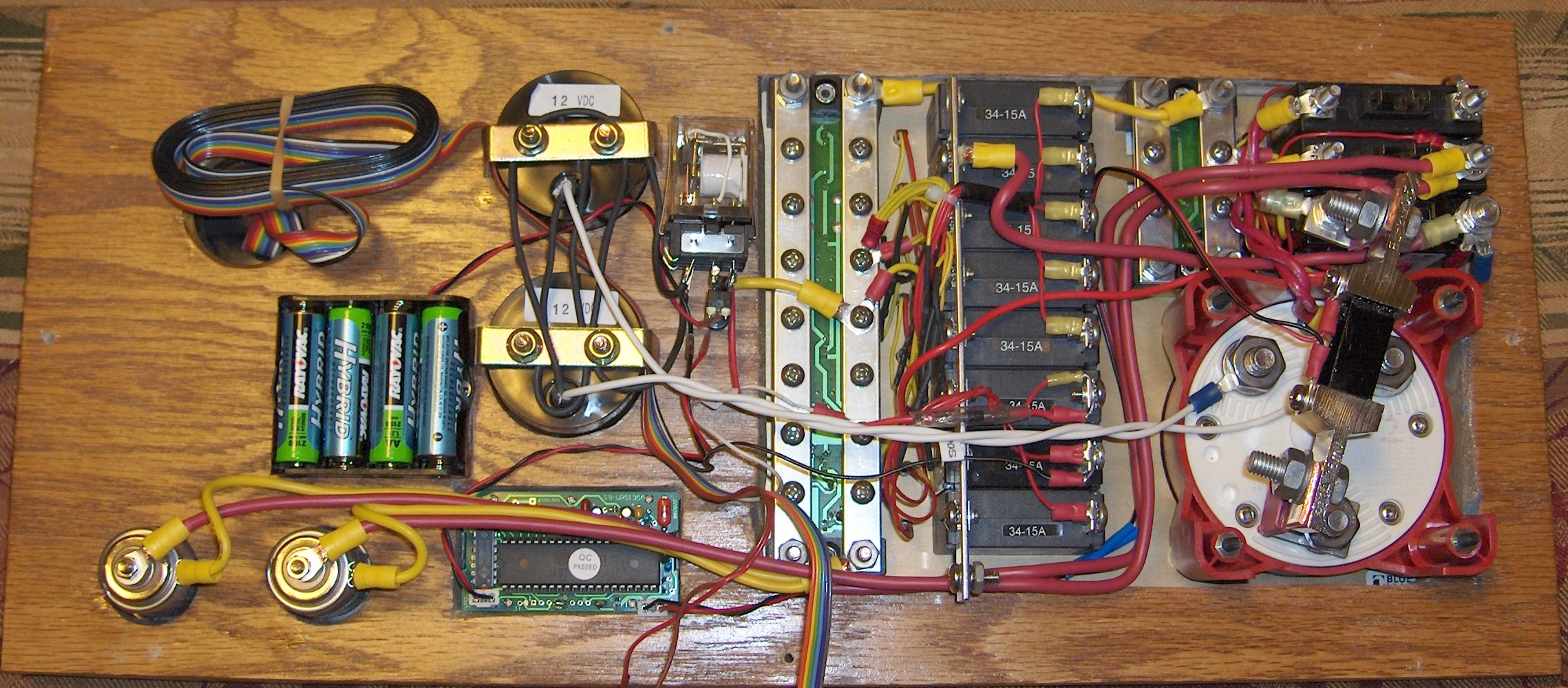

<>The frame and new

installation panel were designed to allow the frame to be attached

to the bulkhead

with 4 wood screws. The panel will be secured to the frame with 4

to 6

screws and can be easily removed. That will allow for me to build all

of the

instruments and electrical panel to the mounting panel and just install

it as

an assembly. The new panel mounts with a 2 1/2" gap just

large

enough for the wiring and instrument backs to clear without hitting the

existing bulkhead.

<>The frame and new

installation panel were designed to allow the frame to be attached

to the bulkhead

with 4 wood screws. The panel will be secured to the frame with 4

to 6

screws and can be easily removed. That will allow for me to build all

of the

instruments and electrical panel to the mounting panel and just install

it as

an assembly. The new panel mounts with a 2 1/2" gap just

large

enough for the wiring and instrument backs to clear without hitting the

existing bulkhead.

This solved the issue of lack of clearance to the engine control panel

that I

installed on the front wall of the cockpit. I recessed the Yanmar panel

to keep

from kicking it.

I decided to change out some of the indicator lights on the panel. I

thought it

would be most wise to have the propane control circuit with a red

indicator and

a red handle circuit breaker.

It the same note of red for dangerous, green should be for good. I

wanted to

have the bilge pump breaker with a green light when ever the bilge pump

was on.

The LED light only draws 15 milliamps which is about the normal

discharge

current of a battery. A 100 Amp-Hr battery would be drained in 9

months, so my

200 Amp-Hr bank would last over 1 1/2 yrs with the LED on. Not a

concern

compared to knowing that you have power to your bilge pump.

Another

circuit I wanted

"green for on" was the refrigerator. It only draws 3 Amps when it

runs and in the fall winter and spring does not run all the time. On

our

November trip the refrigerator loaded with only one bag of

ice, the ice

lasted for 2 days and did not show any evidence of melting. That

allowed the

ice to be used for cooling the beverage of choice. I will change

out this

LED to a green also. The rest of the LED indicators will remain

yellow. The little transparent back lit labels were missing

LPG,

PROPANE, etc., so I had to look for their other label sets. The basis

AC labels

had one that I will end up using.

The

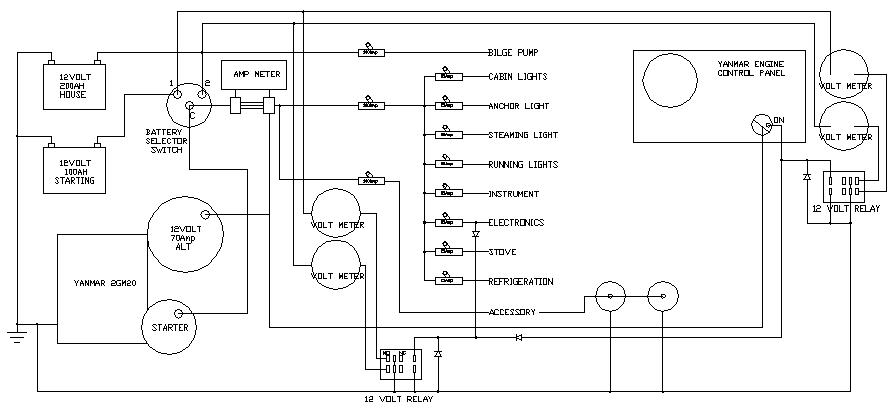

8083 panel is very similar is size and

function as the stock panel. The battery selection switch can be

swapped out

with their newer styles is desired. The stock switch is fine with me.

Some

folks may prefer having the starter on a separate circuit from the

instruments. The current battery selection is:

1) = ENGINE BATTERY, AGM 100Amp Hr

2) = HOUSE BATTERY, AGM 200Amp Hr

The

battery switch labels are "glow in the

dark Phosphors”

and UV lights them up. Perhaps there is another project

there in the

future.....

I'm still trying to find other breakers with different colored toggles.

Red for

the propane made sense. I have not found green ones, may have to use a

black

one to show indifference instead of preference.

The battery

condition indicators

were in interesting search. You have the analog needle indicators,

digital

voltage indicators, and LED driven indicators. I looked over the

internet and

decided that I did not want the computerized talking battery condition

charge

discharge monitors; I just wanted condition at a glance. When I worked

at

National they developed a voltage LED driver the LM 3914 that was a

bunch of

cascaded voltage comparators. You could select the low and hi range and

LED

color of choice. I found a pre-packaged unit that would fit a standard

hole

size that indicated charge condition and when the battery is very low a

warning

LED would flash. Red LEDs for low, Yellow for mid and Green for good

voltage.

I tried it

out on a computer UPS 12 volt battery

power supply. It worked well so I bought another one, one for

each

battery bank.

I tried it

out on a computer UPS 12 volt battery

power supply. It worked well so I bought another one, one for

each

battery bank.

The battery state of charge is indicated by

ten LED's:

5 Green indicates 100

~41%

2 Yellow indicates 40

~21%

2 Red indicates 20% or

less

1 Red indicate flashes

for low alarm

My

goal was achieved, simple display easy to understand and visible from a

distance. It was nice to find the display as a complete unit, I

had

considered using the LM3914 chip and making it, but I prefer to keep it

simple.

The propane controller I decided on has 2 sensors. I

wanted one for near the stove and the other

for a possible cabin heater. I like the Force 10 bulk head mounted ones

with

the small 1" flue. We get together and overnight as much as

possible, even during out low tide period of the year.

This controller

allows for

manual turning on and off the remote solenoid at the tank with

automatic shut

off if a leak is detected.

It has a warning alarm that will

get you out of bed.

The Unit Retains Its Two Separate Channel Monitoring Capability

And Solenoid Valve ON/OFF Switch.

Plug-In Display Module "Fault" Light/Alarm And Separate Sensor/S

"Fault" Light/Alarm.

(Fault Indicators Let You Know The Module Or Sensor/S Are Not Working

And May Need Repair.)

"Press To Test" For Each Sensor Channel Confirms Function.

S-2A Sensors Are Calibrated To Alarm (Visual And Audible) At 20%

LEL (Lower Explosive Limit).

This Alarm Level Is High Enough To Eliminate Nuisance Alarms But Low

Enough To Allow Time To Take Action.

You

can find the controllers at reasonable cost from various

suppliers, even through EBay.

Putting the plan together:

I tried many cad layouts with different options, disadvantages and

advantages.

I tried

various layouts to try to compress it into the

smallest area. This design would allow for the short

existing wires

to reach the new panel location. It was the best to keep the panel on

the left side.

The additional indicators and controller and outlets can be

easily connected

to the electrical panel and the additional cables can be run through

the large

rectangular hole in the bulkhead from the original panel. This is as

far as I've progressed. The new frame and wood mounting panel are being

stained and

coated with urethane for protection. The plan is to install the panel

assembly

first and run the wiring back to the lazerette for the propane solenoid.

One short term compromise is to use a battery pack to create an isolated 5 volt supply for the digital current meter. It draws 25ma, so a 2.2Amp/hr battery pack will last for 4 days almost 100 hrs of continuous usage. It is on a relay that is energized by the navigation breaker. I can power down all of the equipment connected on the breaker and just use it to turn on the power, voltage and current displays. The plan is to buy a 12 volt to 5 volt isolated power converter.

The panel was installed in a few hours and today I modified the Yanmar harness. The alternator 12V output was connected to the large 12Volt battery cable on the starter. I isolated this harness wire and added a 4 gage wire from the alternator to the current shunt. ( 4 AWG is good for 200 Amps and a 100 milivolt drop)When the engine is running, the digital amp display is only displaying the charge current going into the batteries. It is not displaying the additional current from the alternator that is going to the main bus and breakers. Firing up the engine, it displayed around 40 Amps going to the batteries, tapering off to just under 10 amps.

The

epic saga will continue with the stove installation

and the propane locker installation coming soon.

12-12-07 ER.

<>The frame and new

installation panel were designed to allow the frame to be attached

to the bulkhead

with 4 wood screws. The panel will be secured to the frame with 4

to 6

screws and can be easily removed. That will allow for me to build all

of the

instruments and electrical panel to the mounting panel and just install

it as

an assembly. The new panel mounts with a 2 1/2" gap just

large

enough for the wiring and instrument backs to clear without hitting the

existing bulkhead.

<>The frame and new

installation panel were designed to allow the frame to be attached

to the bulkhead

with 4 wood screws. The panel will be secured to the frame with 4

to 6

screws and can be easily removed. That will allow for me to build all

of the

instruments and electrical panel to the mounting panel and just install

it as

an assembly. The new panel mounts with a 2 1/2" gap just

large

enough for the wiring and instrument backs to clear without hitting the

existing bulkhead.

I tried it

out on a computer UPS 12 volt battery

power supply. It worked well so I bought another one, one for

each

battery bank.

I tried it

out on a computer UPS 12 volt battery

power supply. It worked well so I bought another one, one for

each

battery bank.