|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ring Gear Removal and Installation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

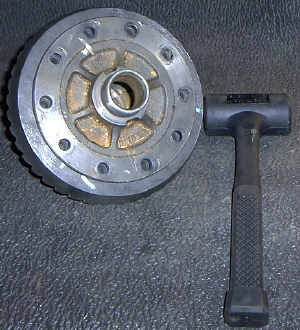

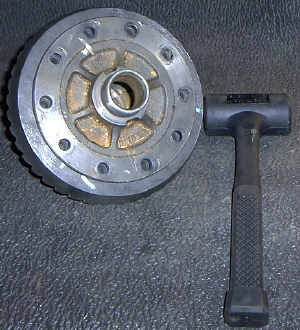

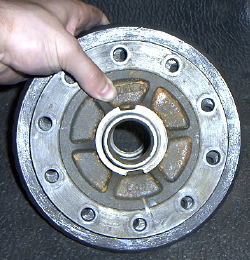

- Using a dead blow hammer lightly pound on the top edge of the ring gear until the ring gear pops

off. It only took me a few blows evenly spaced around the

ring gear.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dead blow hammer used to remove the ring gear from the

carrier.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The cheap little grinding stone I used and stoning the ring gear and carrier surface

|

|

|

|

|

|

|

|

|

|

- The ring gear will need to be pressed onto the carrier and then drawn in using the ring gear bolts.

Our first step in that direction is to fabricate a few

pieces so that while we are in the process of seating

the ring gear the bolt holes line up. You can be creative or you can follow the pictures and use a few

stray

bolts like I did.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

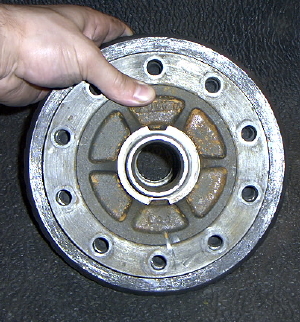

As you can see in the picture the ring gear slides over the carrier

but does not seat without being pressed further down.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The picture on the left illustrates exactly what we do not want; the ring gear pressed on without the bolt holes being

lined up. In this case we would have

to remove it and repeat the installation. The picture on the right illustrates what

we are looking for. We have to have those bolt holes line up.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

One method, illustrated on the left, is to use a smaller diameter bolt

to guide the ring gear onto the carrier so the holes line up. Besides

using smaller

bolts, you can use your imagination to come up with

another piece that can guide the ring gear on.

|

|

|

|

|

|

|

|

|

- Place the ring gear in a pot of boiling water for a few minutes. We want to heat the ring gear slightly

so that it will slide easier over the carrier

flange. If you have access to a press you do not need this

step.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The ring gear in a pot of boiling hot water. I lifted this technique

off a race mechanic I know. This is also used in another

gear install web page on the net.

|

|

|

|

|

|

|

|

|

- Set the bolts (or other fabricated pieces) in place so that the ring gear can be taken directly from the

pot of water to the carrier.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bolts in place and carrier ready to accept the ring gear.

|

|

|

|

|

|

- Set the ring gear on the carrier flange, line up the bolt holes, and apply a bit of pressure downward.

The ring gear should slide most of the way down onto

the carrier.

|

|

|

|

|

|

- Install five ring gear bolts and tighten them in sequence so that the ring gear is drawn toward the

carrier evenly. You will need to brace the carrier as

shown in order to apply torque to the bolts. The

bolts should tighten very easily, drawing the ring gear against the carrier flange very gently.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tightening the five ring gear bolts evenly to draw the ring

gear against the carrier flange. Notice that I braced the

carrier by placing a piece of pipe

through it and resting

that pipe against a stationary object (in this case a vice.)

If you are not rebuilding the Traction Lok you will need to

find another method

of bracing the carrier.

|

|

|

|

|

|

|

- Remove the ring gear bolts and turn the carrier upside down so that any water in the bolt holes

can drain. Allow the ring gear and carrier to dry

completely.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

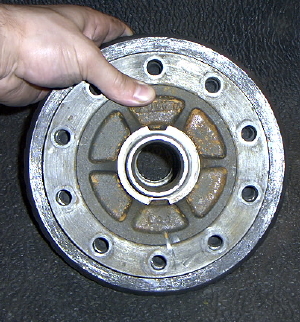

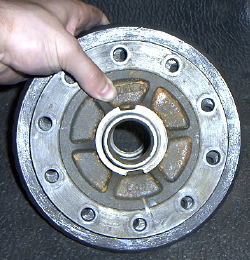

Ring gear bolts removed.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Carrier and ring gear resting so that any water can

drain from the bolt holes.

|

|

|

|

|

|

|

|

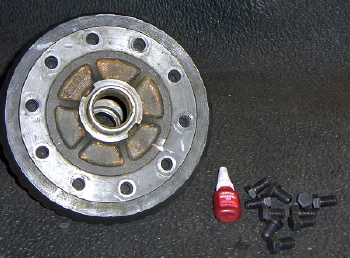

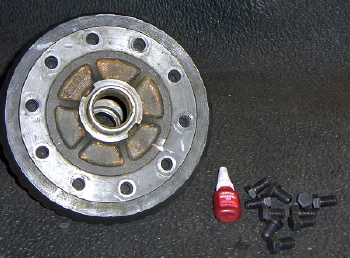

- Install ring gear bolts with blue loctite. Torque in a star pattern to 20 ft./lbs., 40 ft./lbs., 60 ft./lbs.,

85 ft./lbs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ring gear bolts and blue loctite. Don't ask me why but

the blue loctite comes in a red bottle. I picked mine up

at Home Depot for a few bucks.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Coat the threads of the ring gear bolt evenly with the threadlocker.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Go to Page 2

|