DOME PROCESS

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

~~~~

The Dome starts as a concrete

ring foundation, reinforced with steel rebar.

Vertical steel bars embedded in the ring

later attached to the steel reinforcing of

the dome itself. Small domes may use an

integrated floor/ring foundation. Otherwise,

the floor is poured after completion of the

dome.

An Airform -- fabricated to the

proper shape and size -- is placed on the

ring base. Using blower fans, it is inflated

and the Airform creates the shape of the

structure to be completed. The fans run

throughout construction of the

dome.

Polyurethane foam is applied to the interior

surface of the Airform. Entrance into the

air-structure is made through a double door

airlock which keeps the air-pressure inside

at a constant level. Approximately three

inches of foam is applied. The foam is also

the base for attaching the steel reinforcing

rebar.

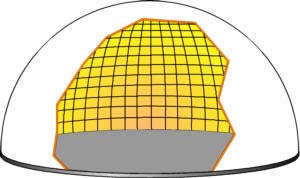

Steel reinforcing rebar is

attached to the foam using a specially

engineered layout of hoop (horizontal) and

vertical steel rebar. Small domes need small

diameter bars with wide spacing. Large domes

require larger bars with closer

spacing.

Shotcrete -- a special spray mix

of concrete -- is applied to the interior

surface of the dome. The steel rebar is

embedded in the concrete and when about three

inches of shotcrete is applied, the Dome is

finished. The blower fans are shut off after

the concrete is set.

Shotcrete -- a special spray mix

of concrete -- is applied to the interior

surface of the dome. The steel rebar is

embedded in the concrete and when about three

inches of shotcrete is applied, the Dome is

finished. The blower fans are shut off after

the concrete is set.

BACK TO

HardRock Domes