All workmanship and materials guaranteed for one full Year!

1. DON’T - Place sharp or pointed objects on your driveway. Indentations will result. This will certainly be true for the first year of its life and perhaps longer (such as on a hot summer day when the mercury reaches 100F or above). Stay off the new driveway 2-3 days after installation and longer if temperatures are hot Principal offenders are high heels, bicycle kickstands, ladders, porch chairs, etc.

REASON - The pounds per square inch on the above subjects is so great. This means that while small in area and light in weight, the weight involved is too great for the area concerned being all concentrated in one small spot. Also, asphalt is not a hard, tight material, but a soft, porous one.

2. DON’T - Drive near or off the edges of your driveway. You may fracture the asphalt and crack the whole edge.

REASON - Asphalt contains no structural strength of its own; it is merely a wearing surface. The strength lies in the stone or gravel base. Therefore, if great weight is placed unevenly on the unsupported edge, it must crack.

CURE - Hopefully your driveway is constructed slightly above

grade, so proper drainage will result. Otherwise,

water will collect alongside the driveway and eventually undermine it.

This means, of course, that the edge is exposed.

To prevent possible

damage, it should be backfilled or supported. This

is why a road or highway has a shoulder or curbing.

3. DON’T - Turn the car wheels sharply on the pavement. Also, don’t turn the wheels while standing still- MAKE SURE THE CAR IS IN MOTION. Otherwise, power steering gouges will result. These are bruises or lacerations to the surface, caused by the kneading, grinding action of the tires moving on the bias against the asphalt.

This problem is most often encountered in L -shape driveways, where the garage sits at right angles to the driveway. The consequent backing, cutting, turning etc. creates this condition. Even cars without power steering or lightweight sports or compacts will cause these marks. Greater care should be exercised in hot weather, since the asphalt is softer and more susceptible to marking.

REASON - Asphalt contains certain oils or volatiles to make

it more workable or malleable. Until they evaporate,

the blacktop will remain soft. This aging or curing process may take as long

as a year, depending upon blacktop thickness, weather,

etc.

“But my blacktop never did this!” Quite possible.

. Older mixes were coarser and therefore more

stable. Today’s mixes are much finer in response to an increasing public

demand for a “smooth” driveway. While pleasing

in appearance, the finer mixes have a greater tendency to displacement

under strain.

CURE - Time is the only answer. Gradual oxidation will eliminate the problem

NOTE - Sealer applied too soon will only aggravate the condition; since it tends to trap the oils that prevents and retards the drying process. After the driveway “sets up” then sealer should be applied. We advise that sealer not be applied before 3 to 6 months, after the driveway is installed.

4. DON’T - Park the car or camper in the same spot all the time. This is particularly true in the case of a dig out where the base is fresh. No matter how thick the material, deep the base, or heavy the compaction, depressions or “wheel dishes” may result, if care is not exercised.

REASON - To place a ton and a half or two tons in the same spot day in and day out over a long period of time can only produce adverse results.

CURE - Move the car around slightly. Don’t give all or most of the wear to one small area. Distribute the usage over the entire driveway.

5. DON’T - Allow overweight vehicles on the driveway. Your driveway is constructed for automobile traffic only. Heavy trucks (garbage, cement, delivery, fuel, etc.) will break up the pavement, since the base is insufficient to take the weight.

Driveways can be constructed to accommodate these larger loads. Of course the cost is somewhat higher, and in most cases the additional expenditure is unnecessary.

6. DON’T - Feel that the driveway should be completely puddle-free. I n areas completed by hand or where close drainage tolerances are encountered, this may sometimes occur.

In addition, subtle shifting of the sub-base may cause some puddling. Any spot holding water ¼” or less deep is almost impossible to eliminate. Many of these small water spots work themselves out with eventual use. The oils present in the new asphalt tend to hold the water on the driveway. However, as these oils gradually evaporate, the water should disappear.

7. DON’T - Allow weeds or other vegetation to crowd the edges of the driveway. You will find these hardy pests burrowing through the stone base and up through the asphalt topping. They will evidence themselves prior to blooming as bumps or minor eruptions in the driveway. Though the base is sprayed with weed-killer prior to paving, it is impossible to eliminate each and every weed seed. Often these air-borne particles are brought in with the stone base or dust binder when it is laid in place. The heat from the blacktop then hastens the germination process.

The strength of some of these species, such as creeping morning glory and dandelions is phenomenal. Instances of their penetrating even concrete are common. Their appearance in no way should be considered a reflection upon the thickness of the material. Application of weed-killer (Triox, etc.) or simple table salt and water should eliminate this problem.

8. DON’T - Allow a driveway snowplow on your blacktop without a warning to the operator to raise the blade slightly. Otherwise, the plow blade may gouge or scratch the asphalt.

How often should the driveway be sealed? With “bargain” sealers, yearly application is practically mandatory. Assuming, however, that a high grade, “GILSONITE” type sealer has been used, it is not necessary to seal every year. Each driveway, of course, is different, but it is not unreasonable to expect a 3-year lifetime. Some will last even longer.

Asphalt contains liquid, which needs time to harden and cure. It will be fully cured usually within 6-12 months; until then it will remain pliable and soft. I recommend keeping automobiles off for at least 3 full days, and longer in hot weather.

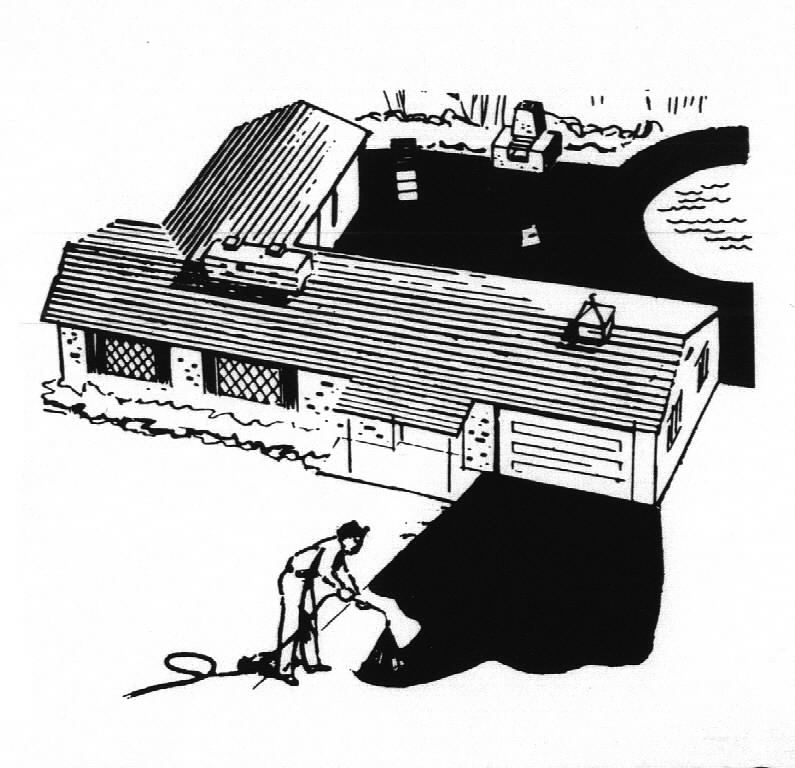

Even when cured, asphalt can sometimes soften in extremely hot weather and harden as temperatures fall, to temporarily harden hot asphalt, you can water it down with a garden hose. If soapsuds should appear, do not be alarmed. This is a reaction between the diesel fuel found in asphalt and the chlorine found in some city water.

Although every effort is made to avoid puddles in your driveway, some shallow ones are inevitable depending on the natural slope and drainage of your ground.

9. CAUTION-To avoid scarring, do not pull out too fast, pull in too quickly, or drive too fast on your asphalt driveway. During the initial curing time, 6-12 months, don’t park in the same spot all the time and don’t use a jack stand or car ramps unless you put a piece of plywood underneath to distribute the weight. Do not turn your steering wheel back and forth when your car is not moving.

Large heavy vehicles can depress and cause ruts in your new blacktop. Keep heavy trucks (concrete, oil, landscaping, etc.) off your new driveway. If a camper or other vehicle will be stored for a long period of time, place a piece of plywood under the tongue jack and tires.

Do not walk on your new drive with pointy high heels, place lawn chairs, bicycle kickstands, or any other sharp objects on it. They will create holes and depressions.

The edges are the weakest part of your driveway due to the lack of side support. Do not drive on the edges, since they will crack and crumble in time. Building up the sides of your driveway with topsoil will support the edges after the grass is grown.|

|

|

|

|