LINE BREAKING

INTRODUCTION

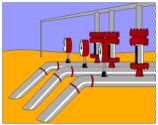

Line breaking is an important process that is needed to clean, repair,

and properly maintain the pipes and lines at your facility. Designing

and implementing a Line Breaking Policy is essential to ensure health

and safety, and reduce the potential hazards. This course will train all

participants in line breaking policy, use of a line breaking permit, and

the proper procedures to follow before, during, and after line breaking

or equipment opening.

LINE BREAKING POLICY

Starting with the definition of line breaking, the participants will

then learn about the potential hazards involved such as dangerous gases,

hot dusts, toxic atmosphere, steam, temperature, flammable or combustible

liquids, and corrosives. It is essential that all workers, including

contract employees, are familiar with your line breaking policy in order

to avoid confusion, accidents, damage, and injury.

LINE BREAKING PERMITS

As part of your line breaking policy, a line breaking permit must be used

to ensure overall safety. In addition, this permit will only allow

trained and authorized personnel to open a line, and only for a specified

job and period of time.

The line breaking permit will act as a safety checklist that must be

completed in writing, signed off, and strictly adhered to. The

information contained within the permit will be discussed with the group

in detail, and will include such information as potential chemical

hazards, personal protective equipment, required safety equipment,

lockout/tagout procedures, emergency response information, and double

checks with sign-off signatures.

PREVENTION OF CHEMICAL HAZARDS

Before any equipment opening can occur, a worker must have proper

training and knowledge of the chemicals that are used at your facility.

This section covers how to gather the appropriate information with the

use of Material Safety Data Sheets, and how to use the information

correctly as it pertains to the work. There is an emphasis on using

the proper solvents and solutions as prescribed by the company as using

the wrong mixtures can be hazardous, and even lethal.

PERSONAL PROTECTIVE EQUIPMENT

This section covers the various types of personal protective equipment

that may be needed when line breaking. Such equipment may include safety

shoes, safety goggles, face masks, rubber or neoprene gloves, split palm

or leather gloves, aprons, acid suits, respirators, and self contained

breathing apparatus. Additional potential hazards such as asbestos

wrapping and lead coating are also identified.

SAFETY EQUIPMENT AND PROCEDURES

Before the start of any line breaking procedure, there will be a need to

clear the area, post warning signs and permits, ensure for proper

flushing and drainage, place barricades, and warn all personnel within

the area.

All workers must be trained in the company's emergency evacuation

procedure and emergency response plan. The use of proper safety equipment

such as scaffolds, ladders, air quality monitors, alarms, fall protection

equipment, fire extinguishing devices, neutralizing agents, and air

moving equipment are covered throughout this segment of the course.

LOCKOUT/TAGOUT

Knowledge of the appropriate lockout/tagout procedures is vital when it

comes to line breaking. Following the permit carefully, and warning all

personnel of which machines will be deactivated will prevent potential

accidents from occurring.

An important part of this procedure also includes careful

de-pressurization and draining of the lines, equalizing pressure,

washing and purging, blinding, blanking, and removing pipes. These

topics, as well as knowledge of supports, pumps, baffles and floats

are also discussed. At this point, each step must be double checked

and signed off by a qualified person.

LINE OPENING PROCEDURES

This section covers the inspection and replacement of bolts, with an

emphasis on theproper technique for maintaining integrity at the joint,

and containment of hazardous residue. Next, we move on to the procedure

for the actual line break, including bonding the pipe to funnels and

containers, clearing blockages, controlling spills and flow, and applying

pressurized agents safely.

CLOSING THE LINE

Upon completion of the work, the lines must be re-connected. The

participants are trained on the proper procedure for joining the lines,

removing supports and grounds, notification of a qualified person of

work completion, receiving authorization to remove the lockout/tagout,

and restarting the equipment.

CHECKING THE WORK

To close out the procedure, the group is instructed on how to check the

lines for leaks, remove the barricades and other safety equipment,

record the time and date of completion, removal of PPE, and proper

cleansing agents to be used. In addition, we stress the importance of

completing the permit in full, including signing and dating the form,

and filing the permit in the appropriate location.

RETURN TO SAFETY 1ST - MAIN PAGE"

Safety 1st

P.O. Box 21044

84 Lynden Rd.

Brantford, Ontario N3R 7W9

Phone: (519) 758-0900

Toll Free: 1-877-251-1172

Fax: (519) 758-0900

website: www.thinksafety1st.com