Teflon Harmonica Valves

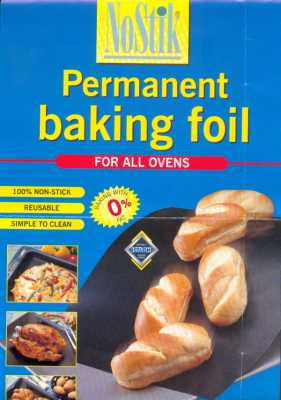

Vern Smith investigated the use of teflon for chromatic harmonica valves. He found only one very specific Teflon product does the job properly: NoStik® Permanent Oven Foil. And you can buy it online.

Vern Smith wrote on

Mon Jan 29, 2001

I "discovered" and tried teflon valves several years ago and shared my experience on harp-l. The harp-l archives should have a lot of discussion between me and Doug Tate about them.

The material is made by DuPont and is marketed as "Bakeware Liner" with

kitchen accessories. It is a little hard to find...I suggest that you call

DuPont at 1-800-986-2857 to find out where to buy it.

(or try

NoStik® Permanent Oven Liner)

I don't think it has been very successful as a kitchen product so when you find some, get enough

to last you. I have what is for me a lifetime supply because I do not use it

commercially and because I am old as dirt.

The material is Teflon/PTFE coated on fiberglass fabric. It is used as a single-part valve. Douglas Tate suggests that if particular care is taken that it lies flat at installation, it will remain so.

The non-stick properties of Teflon seem to make it less susceptible to sticking. The material is unaffected by moisture and different temperatures. The fact that it is single-part avoids the most common source of curling...the two parts stuck together by gunk.

I have tried Micropore laminated on mylar (some purchased and some home-made) and had trouble with them curling away from the reedplate. I prefer the teflon valves. I have successfully used just the .002" mylar without the Micropore against an engraved reedplate.

My "belt-and'suspenders" way of avoiding valve problems is as follows.

It is OK to publish the above in any non-profit medium for the benefit of all chromatic players.

Your mileage may vary!

Vern

Douglas Tate said on

Mon Jan 29, 2001

Further to Vern's post about the teflon valves.

Vern is quite right in what he quoted me as having said. When these valves are well fitted they stay FLAT... the just DIE in place.

Quite frequently this stuff comes in rolls. Inevitably, when you unroll it there is some curvature left. You can try to take the curve out completely of the whole sheet but we wait until the material is cut into 1/8" wide strips.

After a LOT of experimenting we have found that a strip about 6 1/2" long is great...(the sheet is 13 inches wide.) We cut a couple of dozen strips and keep them in a stoppered tube. (easy to slide them out and they lay flat in there)

To get rid of the curve in the material, if there is one, do this.

On a piece of white paper draw a black, thin, straight line. If you now look down on the paper and hold the end inch or so of the strip on edge a few inches above the line you can see if it is straight because it will disappear into the line. For even more accurate 'measuring hold it a tiny bit to one side of the line... it is easier to judge the straightness by the amount of white between the teflon and the black line!

If you see that it is curved smooth out the curve between thumb and forefinger. and check again... ONLY work with a bit more than a reed length... then glue the whole strip onto the reed plate. When the glue is dry slice off the unwanted bit. **Tip** Slice it level with the corner of the reed pad next to the reed you are doing in the same hole. That is where the end of the slot is.

This sounds fiddly... and is. We have been putting these valves on Renaissance harmonicas for two years now. We have one VERY wet player who finds that they last many times as long as standard or micropore flaps before needing washing... and he finds them easier to wash. If you are a wet player you will stick ANYTHING in time :) I have got one valve that is starting to stick after two years and will wash it ...... tomorrow ... maybe.

This information may be used in any non profit making way. Any alteration to the wording MUST be approved by me.

I have to repeat our debt to Vern for pointing us to this material and being kind enough to send us a sample in the first place.

Douglas Tate