Looking for A Plastic Mold Company?

A Plastic molding company works on injection molding machine and plastic mold, meltdown plastics and inject it into the mould by high injection speed. Once the plastics is in the mold cavity, it forms the shape of the object you desire, after the resin get cold in the mold and eject out, then we got the molded part, this one complete cycle time is plastic molding technology or molding process, the machine is standard machine but the mould is custom made for every part feature and shape. For example, there is an iPhone case molded parts, electronic housing molding, plastic storage containers, house cook molded parts, every plastic part that needs a custom mould. However, most moulds are used for a more complex design like an automotive mould or toothbrush handle, aircraft mold and more.

The molding process creates stronger and more durable products and it is a more efficient process with min plastics waste, almost 80% of plastic parts are made by plastic molds and molding technology.

Today, companies are willing to take on orders that are large in quantity and short on time. They use small and large machines to provide state of the art injection molds. The injection molding process is not limited to one material. Companies use thermoplastics, thermosetting polymers, metals and glass to help make moldings. A computer is used to assist skilled machine operators and their quality assurance team in the precision of every plastic mold

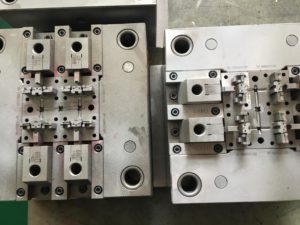

Custom Plastic Mold

The most important part of manufacturing injection molded parts is the custom plastic mold & injection molding machine. This is done by injecting melted plastics directly into the custom mold by the injection molding machine, then allowing it to cool and form the desired part shape, and eject the molded part out of the mould, this finished one cycle is called injection molding process.

Manufacturing custom plastic molds make up an important part of the mould business. The injection tooling making technology is an important factor in recognizing the company in manufacturing high quality or low-quality moulds, moldmaker must have a perfect manufacturing technology before start cutting steel.

When the custom mould is ready, the next step is injection parts (mould trial). Before starting to trial the mould we need to verify a couple of issues to avoid any mistake, we need to check the plastic material, color, cooling channels, surface requirement, mould temperature requirement (this is determined by the plastic material), part volume (need this information to confirm the tonnage of injection molding machine uses). After all of this information has been verified then we start to inject plastic molding samples.

Assuming you have a good understanding of the market you are targeting and some supplies to use on your project, you can make some of the finer detail changes to the product created in the mold. Plastic is a compound that is easily molded into all kinds of shapes and sizes. From molding toys, tubes, jars, bottles, and countless other items that we all use on a regular basis, these are all made of plastics. The high consumer demand for these products has made it necessary to manufacture them on a massive scale. The usage of goods utilizing plastic products has also increased, causing a higher volume of production.

Taking into account that plastic items today can be easily personalized, most injection molding companies have established high-quality control procedures. This has also been a result of the development and advancements in the technology used to make plastics. These manufacturing companies use the thermoplastic injection molding technology, along with other molding processes and systems to meet the requirements of their various client requests.

Obtaining the plastic molding parts for use in the automobile industry are inexpensive. The plastic mechanisms that are produced come from several different injection molding techniques used by manufacturers. These different techniques include structural foam molding, solidity molding, thermoforming, blow molding, thermoset injection molding, thermoplastic and transferring to resin to mention just a few.

Do you have any custom plastic mold & molding requirements for your business? Contact us now

We offer mold manufacturing and injection molding service, also offer additional services like painting, plating, silk-screen, contract manufacturing, and assembly the components along with the plastic products.