How Double Block & Bleed made

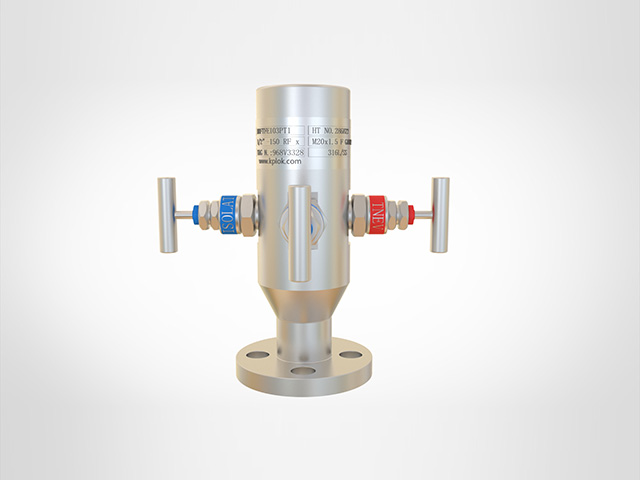

The term double block and bleed primarily meant 2 separate block control devices with a bleed and pipe valve between the valves to check for leakage. The block and bleed valve has 2 free seating slips that are automatically expand against the body seat by the downward action of the tapered plug. The seating slip will close with both low and high force imposed on both downstream and upstream sides of the control device. With the product now the trapped in the center cavity between the 2 independent slips and the body bleed control device can be opened to confirm hundred percent positive shutoff as low or high force,kp-lok.com.

In the conventional assembly the force tools, both the instrument and piping departments are involved in ordering and stocking separate control devices, gasket and other fittings. Assembling so many parts can be costly, particularly if joint welding is needed, and procedures up to eight potential leak points, while also taking up working area and generating a big bending moment. The higher mass can also bring on vibration stress failure, " Wade Brandon says, Sales and marketing, Vice present." Our special approach for top force applications delivers an affordable, out-of-the-box solution, with decreased installation costs, lower height and weight, fewer leakage points, that needs no mounting brackets and that is largely unchanged by system vibration, he says.

DBB valves are hundred percent tested to make sure fast start-up and best operation out of the box. They meet both tool and piping engineers features and deliver important saving on area, cost and weight when matched with old double block and bleed valves. As an outcome they are well matched for use in important applications such as double block and bleed, primary isolation, force tool devices, sampling force equalization, among others.

Double block and bleed control devices are accessible in a big range of stuffs of construction to relax specific application needs. Body and end flanges are accessible in duplex steel, stainless steel, and super duplex. Seals spec PEEK seats for amazing resistance to heat, chemicals and wear. Further materials are accessible for top temperature service.

DBB valves are rated for use with working force from 10,000 or 15,000 psi and spec a special trunnion ball shape for highest performance low-torque and smooth operation. They give full traceability of stuffs, and a blow-out proof stem for raised safety. They are accessible with clamp-hub kind ends to relax API 17D feates, and can be made to relax NACE MR-01-75 for decay protection.

Saves time space and cost

DBB save space, time and cost by decreasing weight in critical places, eliminating extra piping needs as well as the need for expensive multivalve systems. Addition to removing tool for repair or service while the facility continues in operation, you can use it any place you want to stop product contamination. The DBB valve can also be used in multi-product manifolds.

Updated: Saturday, 20 July 2019 1:01 AM EDT

Post Comment | Permalink | Share This Post