| Tech Tips | Trick Tips | Racing Prouducts | Sponcers | The Team | Pictures | Schedule | Tracks | Racing | Contact |

HOW TO: REBUILD YOUR TOP END (2Stroke)

Changing your top end or just your rings are one

of the most important maintenance skills to have.

If you ride or race a lot, you may be changing

your top end often. To find out when you should be

changing your top end, check the Maintenance

Schedule.

THE PARTS:

-Piston

-Rings

-Gasket Kit

-Wrist Pin

-C Clips

STEP 1:

STEP 1:

Remove the exhaust by removing the springs that

hold the pipe to the cylinder. Then remove the

bolts that hold it to the frame.

STEP 2:

STEP 2:

Remove the radiator hose from the water pump area

to allow all of the coolant to drain out of the

system. While the coolant is draining this is the

perfect time to remove the seat and gas tank.

STEP 3:

STEP 3:

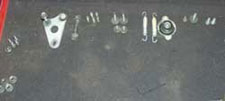

This is more of a reminder of a good practice than

a step. Make sure you lay out all your nuts, bolts

and hardware in an orderly manner so that

reassembly is just as smooth as disassembly.

STEP 4:

STEP 4:

Loosen the Phillips head clamps that hold the

carburetor. I usually leave the sub frame in place

and just work the carb out and lay it to the side.

STEP 5:

STEP 5:

the coolant. Otherwise you will be following this

step.

STEP 6:

STEP 6:

Remove the six bolts (commonly 8 mm head) that

hold the reed cage in. Inspect the Reeds for chips

or cracks. Also check the rubber intake boot for

cracks.

STEP 7:

STEP 7:

Disconnect any external Power Valve Linkages that

you may have. Yamaha owners will have to deal

with this set.

STEP 8 :

STEP 8 :

Remove the motor mounts that connect from the

head to the frame. This should be 3 bolts and 2

brackets.

STEP 9:

STEP 9:

Loosen the six 12mm head nuts that hold the head

on the cylinder. I only loosen them right now to

make it easier to get off after we pull the

cylinder, but we won't get any dirt in the moto if we

leave the head in place. Remove the four nuts

that hold the cylinder to the crankcase and

slowly and evenly lift the cylinder and head off the

motor.

STEP 10:

STEP 10:

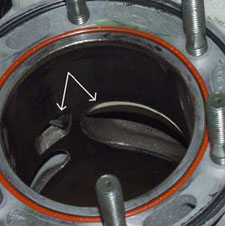

Check the Power Valve assemblies that are

sticking down in to the exhaust ports. They should be

clean and free moving to insure proper function.

STEP 11:

STEP 11:

This piston shows some signs of wear but still is

well within the service limits allowed. Remove

one of the clips that hold the wrist pin in

place. To do this you will need a pair of needle nose

pliers. Slide the pin out and remove piston and

bearing from end of rod.

STEP 12:

With the way that the cylinders are built today,

unless you have an excessive amount of dirt go

thru your motor, ring break, piston clip come

out, or crank bearings go bad, you will not have

to worry if the cylinder is wore beyond service

limits.

Its Rebuild Time

NOTE: It is a very good idea to place a rag or

paper towel over the opening in the engine while

putting the bike back together. There are many

small pieces and it is not fun when you drop one

into the bottom end.

STEP 13:

Insert the new C Clip into one side of your new

piston. This can be a bit tricky, so you will

have to be patient. Use a pair of needle nose

pliers, get one end in the groove, then twist the

other end into the groove as well. If you put

your thumb over the end that you put in the

groove first, it will be less likely to pop out.

STEP 14:

Coat the wrist pin bearing with the same 2 cycle

Pre-Mix oil that you put in your gas. Prior to

putting the piston on the rod, slide the wrist

pin half way into the piston.

STEP 15:

Place the piston over the end of the rod, oil the

new wrist pin (Pre-Mix Oil) and slide into piston

(Make sure you put the piston in the correct

direction. Most have an arrow on the top that points

to the front of the motor. The other means of

identifying direction is that the intake side

(back) of the piston will have a cut out in the

skirt. Refer to piston pic above). Put in the

other piston C clip so that the wrist pin cannot

slide out.

STEP 16:

Put the new rings on the piston. Install the

bottom ring first and then the top.(Depending on your

bike, you may only have one ring.) In 2 stroke

motors both rings are the same so you don't have

to worry about which one is the top or bottom

ring. To put the bottom ring on, put the end of

the ring in the top groove and roll it onto the

piston bypassing the top groove with the other

end and placing it in the bottom groove. Continue

to roll it around until it is completely in the

bottom groove. Then install the other ring in the

top groove on the piston. Refer to picture of

rings above.

STEP 17:

Align the rings to that the end gaps are over the

locating pins in each ring groove. Compress the

rings with your fingers and slide the cylinder

over the top of the piston. Once the piston and

rings are up into the cylinder continue to slide

it downward as far as possible. You can also

slowly move the kickstarter to bring the piston up so

that you can seat the cylinder back down on the

crank case.

STEP 18:

It is simple from here, Begin replacing the nuts

for the cylinder and torque to proper specs. Now

put the head back on and torque the nuts in the

proper sequence and to the proper torque. The

Torque spec is very important! You can get these

from your owners manual or local dealer.

STEP 19:

Reinstall the reeds and intake boot. Remember to

Torque properly.

STEP 20:

Reinstall the carburator and tighten the clamps

that hold it in place.

STEP 21:

Reinstall the radiator hoses, fill coolant to

proper level, seat, gas tank, and exhaust. Put in

a new spark plug.

STEP 22:

Double check your work, make sure bolts and nuts

are properly torqued and everything has been

reinstalled.

STEP 24:

Now you are ready to start your machine. Allow it

to run until warm, shut it down and allow it to

cool fully and recheck all nuts and bolts for

proper torque.

STEP 25: BREAK IN

There are many different theories on break in

procedure, so here is ours. Basically, when

breaking in an engine, you do not want to strain it in

anyway, never go above 3/4 throttle, don't ride

in sand and try to keep it on flat ground:

Note: You will be riding the bike at half

throttle. To avoid fouling the plug, you may want to

install a hotter one.

1) Start the bike and warm it up. Ride for about

10 minutes at half throttle. Shut it off and

allow it to cool.

2) Check for any leaks and noises and pull the

plug to check it.

3) Start the bike, warm it up and ride for about

20 minutes. Shift through the gears, but do not

use more than half throttle. Allow the bike to

cool. Check all components of the bike, look for

leaks and check the spark plug.

4) If the bike looks good, not making any funny

noises and is not leaking, you are good to go and

the bike is ready to be put through its paces.