LS/VTEC

The Process continues...

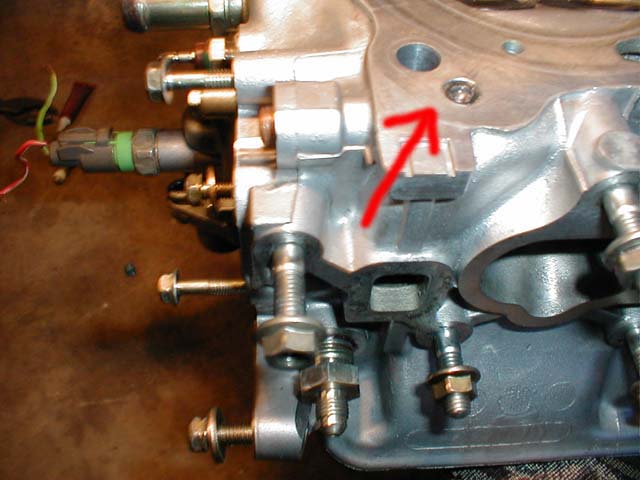

Tapping the oil passage

Make sure the plug is completely threaded down and

blow the head surface. If it's not, you may need

to have a machine shop resurface the head until

you get a completely flat surface. Should not cost

no more then $90 for the head to be

resurface. Also you can choose to have the shop

weld the passage instead of tapping it yourself.

Relocating Dowel Pins

The B16a/B18c1 dowel pins is located on the

opposite side of the head as compared to the B18b/A heads.

So what needs to be done is relocate the dowel pins

from the Exhaust side dowel holes to the Intake side.

The dowel holes @ the intake side will need to be

mill to fit the dowel pins. Use the correct size

drill bit for dowel pins.

After the two holes have been milled, make sure all

metal shavings is removed. The B18b/a Non-VTEC head

gasket will line up perfectly with the dowel holes moved.

This should be a very straight forward procedure.

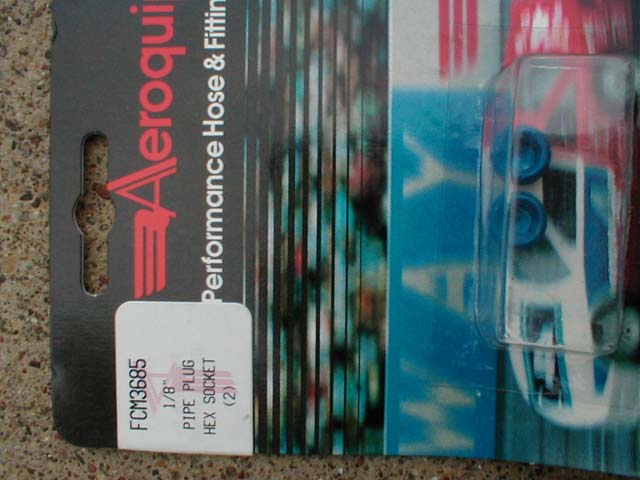

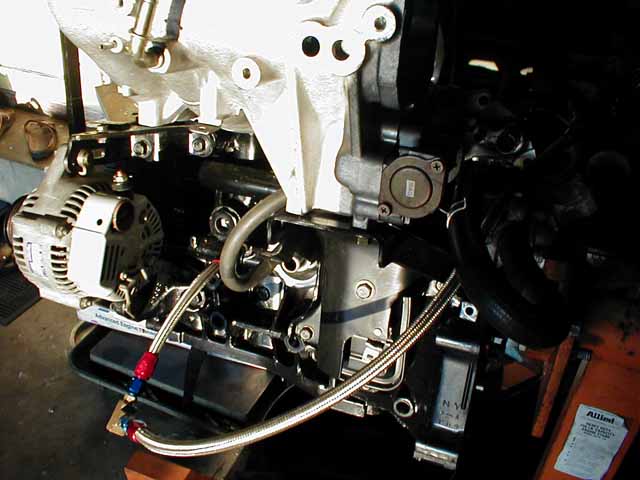

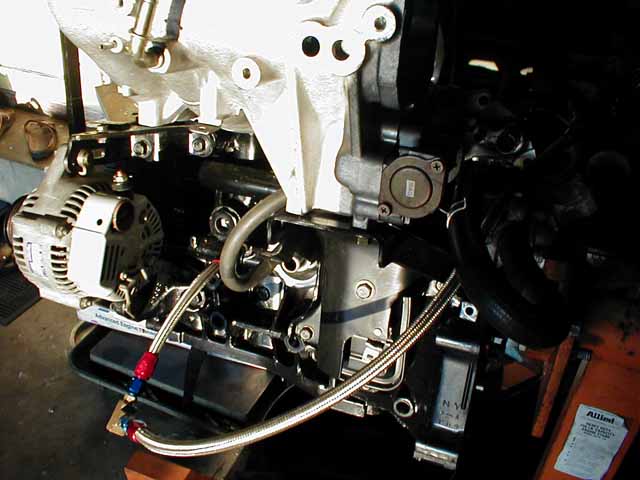

External Oil sending lines

Cut the second SS lines about 10" to 12" inches long.

Make sure you use Teflon tape when connecting the 3 flare adapters

to the Tee and the 1/8BSPT adapter on the block.

As for the Oil pressure sensor, connect it to the end of the female

Tee fittings as illustrated in the pix

Additional details on Oil Lines Install

There are many ways of doing this. You may seen other instructions on how

to Tee the oil sending unit directly from the block.

But, I don't recommend Tee'ing the oil sending unit directly off the block.

Doing this could break and snap the fittings under harsh engine shacks & jerks.

ENDYN Articles On Oil Pressure Gauge Install

C/R (Compression Ratio) for the LS/VTEC

(B16a head on B18a/b block w/stock b18b rods) motor:

9.6:1 - P74 LS Pistons

10.0:1 - P72 GSR Pistons

10.8:1 - P73 US ITR Pistons

11.0:1 - P73 JDM ITR Pistons

11.5:1 - PR3 Pistons (1st Gen B16a)

11.7:1 - P30 Pistons (2nd Gen B16a)

12.4:1 - CTR Pistons

&

This is with the LS block with LS rods and a GSR (B18C1) head:

9.8:1 - P74 LS Pistons

10.2:1 - P72 GSR Pistons

11.0:1 - P73 US ITR Pistons

11.2:1 - P73 JDM ITR Pistons

11.7:1 - PR3 Pistons (1st Gen B16a)

11.9:1 - P30 Pistons (2nd Gen B16a)

12.6:1 - CTR Pistons

11.5:1 C/R is the "Safe" or target on 92+ oct street

pump gas.

*these numbers are rough estimates

Bojangz EZ B-Series CR Calculator

Next Time, we'll be swapping out the B18b1 slugs for some higher

Compression Ratio B'series VTEC pistons...

Upcoming swaps setups included fabricating a single-

layer headgasket, & installing new ARP head bolts.