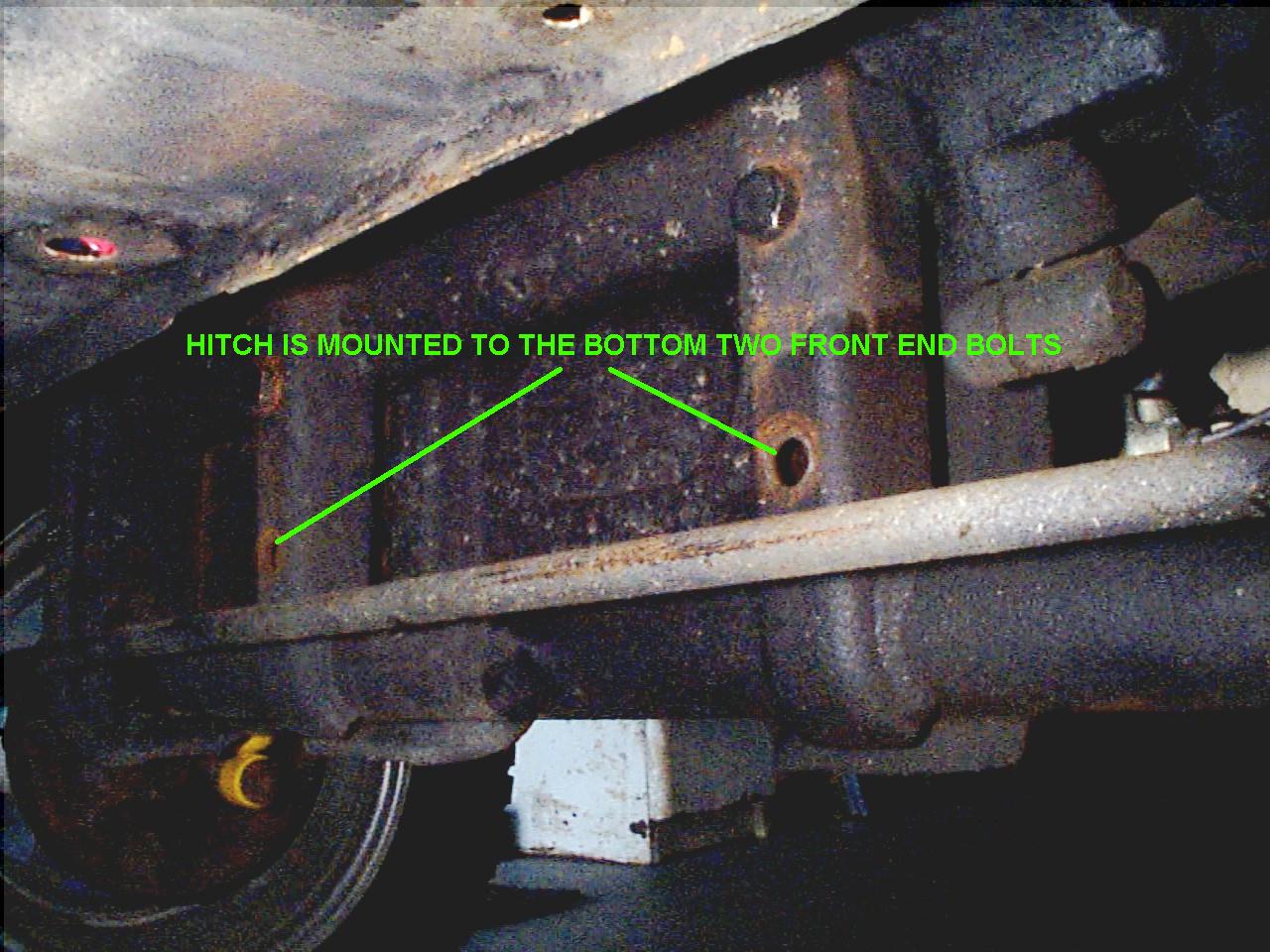

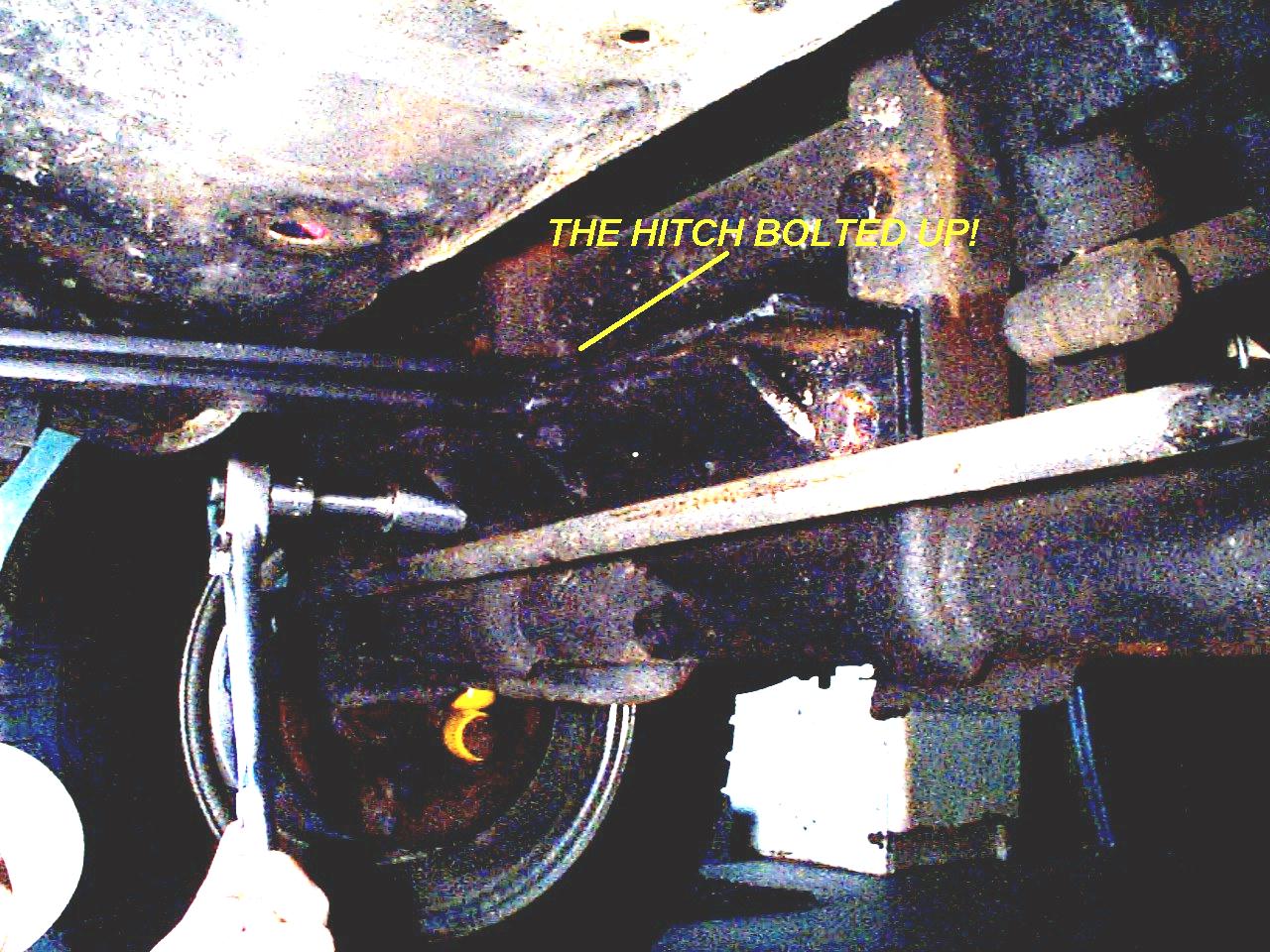

Well thats all the pictures, the duckboards are made out of 1"x2" furring strips, they are cheap andget the job done. I just made a cardboard template of the floor, and half lapped the joints to make them sturdy, screwing them together. They look great and wear nice. Just a tip, on the underside attach no slip carpet stuff, that rubber webbing you place under small carpets so they don't slide around. This will quiet any raddles, and lift them off the floors eliminating rust problems. Now as far as the winch goes, you have to make the hitch cause they are impossible to come by. I made the bar out of two pieces of 1/4" thick X 2" wide steel bar stock, I doubled them up to get a 1/2" thick bar. I know its over kill and rather beefy, but why not make it last! Then I took two pieces of 1/8" thick X 2" wide angle iron and doubled them up. Bolt the bar to the center of the angle iron, get it all welded and place two 3" long 1/4" thick bars on the angle iron on both sides of the bar to give the angle iron more strength. See the above pictures, they should clairify any questions you have right now. I had mine MIG welded for about $30 bucks, total cost was about $50.00 and its stronger than you can imagine. You should have seen the face of the guy that welded it, all he could say was your putting this on a thing, why, why so thick, for what?? Oh well, you had to be there. I know these directions are sketchy, I don't have any measurements, thats cause I'm at school and forgot to bring them with me. I get out in May, so when I get home I'll measure up the hitch and add the measurements up here for ya. Have fun making it, take your time cutting the steel, it is thick so I used a steel cutting blade in a jig saw, worked great!!

Email: jimgeno@bgnet.bgsu.edu