Kadee Couplers 26/8/2004

I have been using Kadee couplers now for over 20 years on my H0 models with excellent results.

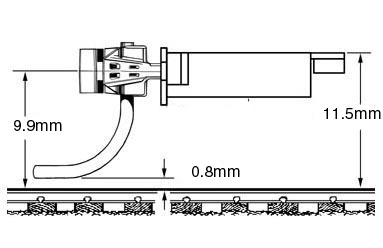

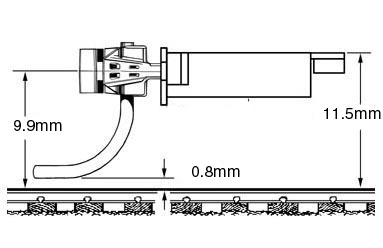

The trick is to mount them at the correct height and on centre. I check all my couplers height with the Kadee coupler gauge.

Mounting Kadee couplers has been a problem on many models, even though there are a number of types to choose from. One reason is most Kadee coupler boxes are wider than the prototype. This means that wheels on bogies will rub against body mounted couplers on commonly used model railway curves, causing derailments. Another problem was that if you model a prototype that uses buffers and hook coupling, the standard length Kadee was to short. The over scale standard Kadee coupler size also could cause clearance problems on passenger carriages with diaphragms.

One solution I used to solve a tricky situation was to glue a long shank KD onto the headstock of my 57 class locomotive. It works for large curves but the coupling on the tender or carriage connected to it needs to be mounted conventionally.

Fortunately Kadee have now introduced new scale couplers, the No 58 and No 78. The No 58 uses the over scale No5 box, which has become the standard box in many ready to run models. Thus installing the No 58 is easy in many cases. However the pre assembled No78 is the best and most useful coupler to date the Kadee company has made for H0 scale in my opinion. I have found both these new scale couplers are 100% compatible with the earlier Kadee couplers.

The Kadee No78 solves a number of problems the older couplers had.

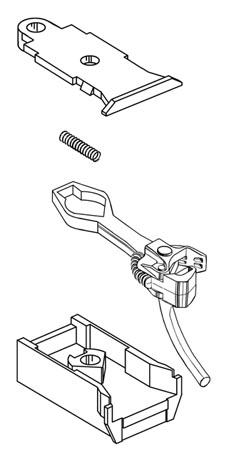

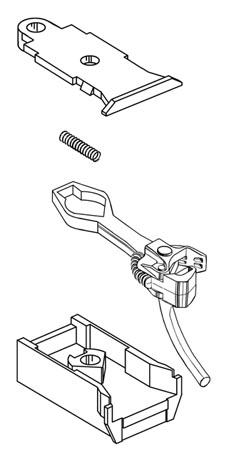

It comes pre assembled, and is closer to scale which makes it easier to install. It does not suffer from coupler drop that is a feature of the popular No 5 box.

The big advantage of the No 78 is you can use it for prototypes with buffers. The box can be cut back close to the pivot point without any problems with coupler drop. Cutting the box back also allows a scale headstock to be modeled. Cutting the box can be done using a sharp razor blade, without disassembly. If you are cutting most of the front off, the assembly can easily fall apart.

The above picture shows a comparison between a No78 with a cut back box and a long shank No 26. Because the No 78 is a standard length coupler, pushing long trains does not result in the coupler kicking to one side, a problem when mixing long KD couplers with standard length ones.

I am now replacing the long shank Kadee couplers with No78ís. The tender above shows how using the No78 results in a smaller cut required in the headstock. One day I might get around to filling in the space.

The diagrams of the KD No78 came from the Kadee web site.

Kadee site for details on their other couplers

Email: tgflynn@unsw.edu.au