This is a BIG article, let it load!

First Impressions:

Big kit, big box, big price tag. I got a second one at Hobby Lobby for half off, which brought my total to $26USD!

A couple of hundred parts with fair to soft molding, but thats not really a problem. Full interior detail with the best crew

seats I have seen. Super crisp clear parts and options for the outer wing tanks. A/L version has standard M60D guns with

fairly good detail.This will be a BIG model, with a overall lenght of just over two feet. Even if you plan to build this

thing Out of the Box, you will spend at least 20 hours building it, so plan accordingly.

I cut each peice away and cleaned it up prior to starting the kit, which seems to save time for me. I painted my kit with

overall Helo Drab by model master, and then applied a custom sand mix over scrubbed-on rubber ceement in accordance with

published photos of Tinnin.

A series of buildup articles have been featured at Aircraft Resource Center

and you can reference these articles as well for construction tips.

The time has come and at this point most modelers give up on this kit, close the doors and blast it with green.

Not so! Follow me, and you willhave not only a convincing model, but one that will amaze and astound your freinds!

*yes, believe it or not I DO have a life!*

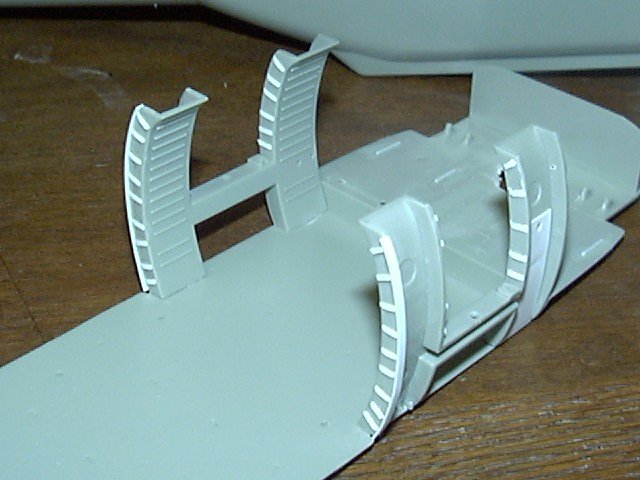

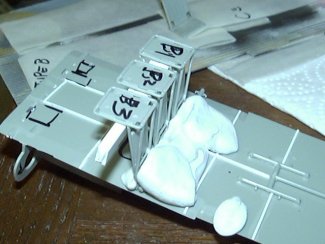

Y ou will be making a total of 12 troop/ crew seats, dont be led to believe that there are 11 troops seats, there are only ten.Remove each part from its sprue with new Xuron shears, clean that part and make damn sure you bag it with like numbered parts, these parts are not only different but look the same. I used baggies and marked boxes just to keep it all organized.

If you follow the kit seat installation insructions, you will go nuts. Try this instead:

Assemle your seats by row, the back row (mark on the bottom, see pics) being row # 3and the CE seats being marked L and R as well.

Each set has different hooks at the top and thier legs are oriented differntly. Start anywhere and build up the seats but leave off the legs. Temporarily assemble the roof to the back wall and broomclosets, and add your row of seats, allowing them to hang from the roof. Use a big tubular hunk of plastic and wedge the seats in place, and use more

poster putty to get them just right. When its all adjusted, go ahead and put a drop of cement on the part of the leg that will attach to the seatbottom, after it sets for a minute, pull the roof off the broomclosets and add the legs. Let the glue set up a bit, and allow the legs to hang as they will. the idea here is that when the seats/roof are reinstalled, the legs will be compresed to the proper shape. Dont forget that the seat legs dont just hang down, they point aft to a central point between each seatback, except for the outermost leg, which hangs straight back. All legs point aft in all cases. Study the pics here and you will get a better idea of how to do this. In fact, this process will take three nights, and you will find it much much easier than going at it one seat at a time. When your all done with a row, pull that set out and set them in a

box away from everytihng, ready to add any PE and paint. Make sure they are marked with position and row before you pull them out! I pulled an image of a US flag off the web, shrunk it down and mounted it inside the back wall behind the back row of seats. Thsi was a common practice during Desert Storm and an easy detail to add.

I added simple solder wire wiring for the CE commo cords and coiled that up, they should be long enough to loop back up on themselves, and small handles at the upper corners of the CE windows. The CE seats got simple commo footswitches added, as well as thier respective seatbacks. Each and every seatback has a nylon storage pocket. The front of the seatback is velcroed on, and it pulls off for whatever junk the CE has in there. Sometimes I use foil or paper to make the upper shoulder belts stowed inside of the seat, a very convincing trick, and I usually let a corner or two fall, since the real velcro wears out.

add stowage to the CE seats with putty between the back frames. (P 12-14 Walkaround) Does it show? you bet it does! Doing this is worth the effort you are putting into it. I painted the X shaped crossbraces

seperately on the frame and added them to each seat before I installed it on the upper rail during final assembly.

With most of the interior done, we can add further outside details. I made new tiedownrings from thick stock and wire, drilled out holes for the wiring from the Chaff and Flare dispensers and wiring from the ALQ 144 "disco light". Part D31 will not fit correctly so you will need to twist it to fit inside the molded receptacle and you can add Grandt line boltheads for detail. Its been said that you can leave the rotors unglued and push pull them out---I broke three of the mounting tangs, so they are not epoxied in place with tubular brass stock. The rotors got a set of wires from the central Bifolors mount out to the individual blade, entering it at the front where a molded nub is. That is an electrical cable for the de-ice strip. Each blade had its aft nubs carved off, and replaced with sprue for the shcrader valve and clear epoxy over sprue stock for the Blade Health Monitor. Overall black MR blades with helo drab green dynamic components components. You will find that if you build it up as in step 1, you will havce no place to put it! do this last... Tail Rotor blades are simliar, dark metallic grey hub, olive green paddles, with a dark metallic anti-erosion strip. I love the decals, they add a lot of character to the blades!

FINAL ASSEMBLY

Wow, if you have read this far, you are as dedicated to this project as I was when I built it.

Now, lets get it all together and paint it. I chose the Tinnin option with its scoreboard of POWs carried, since I really love these worn out flakey faded schemes. Do your final assembly, and close of your interior with card or the doors, as you prefer. I used the excellent UH60 Black Magic Masks from Meteor Productions, and they are awesome!. Here is my color scheme:

overall helicopter drab, then shaded with black over heavy panel lines and dark spots on the real thing. I mixed up Marine Corps Gulf Sand, Sand, Armor Sand and a touch of light grey for the final overal color,knowing I needed to apply it thin in spots and not at all on uppermost and lower surfaces. the mounting point covers for the external wings, rotor hubs, wheels and ALQ 144 are green and did not recieve sand paint.

Walk away, make a baseplate and get ready for the admiration!

You have just completed in a few weeks what I labored over for about a year. Now, knowing what I need to do and what I have shared with you here, you can build yours much much quicker.

I hope youve enjoyed this article, and if there is any other information you need to know, feel free to ask.

Written Christmas Day, 2003. Who knows what next year will bring!?!

Photos © David Campbell