March 23, 2003

I have started the body work on the exterior of the car. As you can see

in the photos below, this can be scary for someone (like me) who

has never cut away parts of the exterior of their car before with an

angle grinder.

The first photo shows the left side area (most MG people call the

"dogleg" panel) cutout. I used an angle grinder to accomplish this. The

repair panel is a piece made to replace only a portion of the original

panel, so it

does not fit exactly where you take another panel just like it off.

I

placed the repair panel up over the area it was going to replace, and

drew

a line across the top with a marker. I have a flanging tool, so I had

to

come down 1/2" from the line I drew to make the line I was going to cut

along. The flanging tool places a .40 mm flange in the edge of the

panel

so that you can attach it to the area it meets, and have the finished

connection

between the two virtually flat, as opposed to one being overlapped over

the other. This worked fairly well except I was not prepared for the

repair

panel to be flatter than the area it attached to. There was apparently

a

bend in the original panel that was not put into the replacement piece.

To fix this, I used self tapping 1/8" screws and drilled them into the

area

where the flanged part of the new metal was behind the original panel.

This

brought the two together with the same degree of bend in both. I took

one

screw out and a time and mig welded the hole where the one screw was

removed

while leaving the others in place. This kept the bend in the panel

uniform

when the welding was completed. The welding part was fun, the angle

grinding

was not so fun.

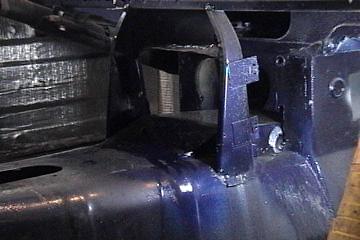

The second photo shows a closer view of the area cut out. There was

some light rust there, so I cleaned the area with a drill and wire

brush attachment. Then I used some rust converter that comes in an

aerosol can and converts rust to a primer like black base coat.

The third photo shows the forward most area that the repair panel

attaches to. Be careful not to cut too much of this away. The repair

panel does

not provide enough sheet metal in this area to attach it unless you

leave

at last as much as I did.

The fourth photo shows the right side dogleg panel. It is rusted out

in about the same place that the other side was. I will be repeating

this

same process again soon on the other side.

Other body work yet to be completed:

The first photo here shows the bashed in front of the left front

fender. Lots of work needed there. The other photo shows rust in the

threshold

of the right side. I have a complete replacement threshold to weld in

here

after I cut this one out. I have read that you should make sure you

have

the door fitted correctly before you take the threshold piece out, so

that

you can weld the new one in with the correct spacing between the door

bottom

and the threshold. This looks like the most complicated of the body

work

tasks I have ahead of me.The bumper mounts look rough too! Not sure

what bumper I will use yet, so I am leaving that alone for now. I can

go back

with the original rubber bumper (heavy and unattractive) or I can

convert

to the chrome bumper found on older MGs, or I can go bumper less with a

Sebring

front Valence (more modern look).

These are some photos I found on the net of an MGB with the Sebring

Valences:

Below is a photo of what the new dogleg panel I installed looks

like (I plan on cleaning it up a bit more before painting).

The engine shop has still not made much progress. The reason I already

painted the engine bay, was because I thought the engine would be

completed soon, Guess I was wrong. We had a really nice weather weekend

this past

weekend so I made a lot of progress. The rain has finally

stopped,

at least for a while. I hear April here is wet though ( I Just moved

here

this past summer).

March 30, 2003

The engine shop suddenly says that my motor may be ready this week.

Things

are starting to come together.

I decided to tackle the rusty threshold this afternoon. Below are

photos

of what the car looks like with the outer threshold piece cut off:

I didn't have time to start fitting the new one so I guess it will be

left

like this for now.

September 15,2003

I have painted the front rubber bumper to match the car color and I

would NOT reccomend that anyone else do this.

The process of getting the bumper to accept paint without bubbling up

was painful. This is what it looked like while I was preparing it.

Before

After

Before

After

Porsche style Boxster vents I decided not to use. They are for sale on

E-bay now!!!.....Well not any more, they sold.

Project

Project