| So how did I do that?

I started with several trips to the hardware store. Home Depot had a

good selection I thought, but that is before I discovered that Ace

Hardware has a much larger selection. The allen cap head bolts are

made with head ridges and are unpolished. First the ridges have to be

ground out, without putting deep score marks in the head. I performed

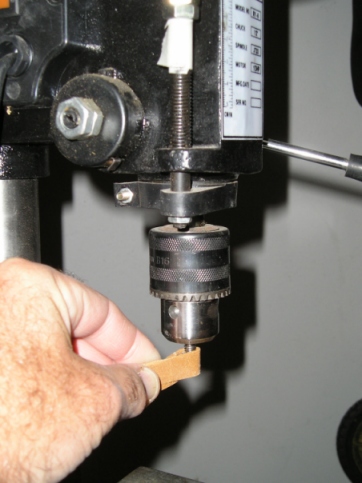

all my bolt operations by chucking the new bolts up in my drill press.

I suppose you could use a hand drill, and maybe clamping the hand

drill into a vise, but it would be difficult. Quite a bit of pressure

is applied to the head during polishing, and the bolt has to stay in

place.

Assuming a drill press is used, chuck up the new bolt. Start with a

grind stone, whet stone, or course grit sandpaper to grind out the

ridges.

Next apply a grit of about 100 to further smooth the head.

Last grit should be 330, things should look shiney at this point.

Finish with a metal polish in a cloth (or Stainless Steel buffing

cake). I've tried both because I have both, and the results are the

same.

That's it. Stainless Steel fasteners that hold up to the

environment much better than anything with a chromey price tag.

"Chops" polished SS on the left...........................chrome on

the right.

|