|

| Introduction to Ecorun |

|

What is "Ecorun"?

|

"Ecorun" stands for the words "ecology" and "running". It is also called the "mileage marathon" since the car that consumes gasoline the least will eventually run the longest distance. It is quite a big competition in Japan since protecting the environment by limiting modern automobile gas consumption is becoming an important public issue. Hence, all the major Japanese carmakers, including Aisin Seiki, are participating and hoping that finishing among the first will show some ecology conscientiousness. A little more than 500 cars, all from different companies, universities and even high schools are participating every year in October at the Suzuka Formula 1 Grand Prix circuit in the Mie prefecture. All motors are 50cc (equivalent of the motor of a scooter) and using the same type of gasoline. The driver must complete 8 laps before returning to the gas station where the tank is taken and the volume of gasoline is measured accurately. Prices are also given for artistic and engineering creativity. Qualifications are held on Saturday and the actual race on Sunday. The qualifications are relatively easy. They consist of a series of tests to prove the reliability of the car of the racetrack. Most importantly, officials check breaks and engine.

|

Aisin Seiki, which is an automobile parts maker mostly for Toyota, has been running for the last 6 years. Nevertheless, it is not what is called a "top team" (that can run more than a 1000 km with only 1-Liter of gasoline!). They hardly make it to the first 200th positions running at approximately 300 km. However, it regards the competition much more as an excellent learning experience for its employees and a way to consolidate interrelations between different engineering sections inside the company. There are six cars from Aisin Seiki, among which, two are from the materials department. These two are simply called Aiming 2 and Aiming 3. The first one driven by Hiratsuka and the second, by Enya.

Before the competition

|

We are about 10 people working every Wednesday since August (and more and more frequently during the last weeks before the race). Since these two cars have been running last year, most of the frame and the engine parts were already in place. Therefore, the workload was concentrated in improving the general performance of the two cars. The shape of the pistons was studied and compared with actual pistons from automobiles. A special mechanical device was also developed to stop the entry of gasoline to the motor rapidly. This enables to cut the gas consumption during descent and at the finish (it is actually the secret part of the car!). It is also extremely important to give the best aerodynamic aspect to the shape of the body and the wheels. Finally, the wheels must generate the least friction possible.

To the right: is Enya working on a new "home made" piston. The upper holes have been polished and the center part slighted elevated to give an optimum explosion distribution inside the engine.

|

|

|

During the last week before the race, we were working until midnight almost everyday and getting more and more tired. But the friendship was getting stronger and the learning experience more valuable everyday. Hiratsuka who weighted 58 kg in August brought it down to 51 kg on the day of the race. He is actually the hero of the whole story. He has been running for 5 years at the mileage marathon and is a great fan of Formula 1 which he attends every year. You can imagine the feeling of watching Hakkinen and Schumaher fighting of the same track you have been racing just a few weeks before! He was working on Aiming 2 even during the weekends in order to improve every little aspects of his car such as to know every little problem that might occur during the race.

To the left: Is Hiratsuka giving a smile while working deep inside the motor? He is the inventor the top-secret apparatus that will make his car save a lot of fuel during descent and finish. His little electronic device is very ingenious! Of course, no photo of it were allowed to be displayed here...

This picture also gives an inside look to the metallurgy laboratory where I am working most of the time. This is also where I am currently constructing this homepage.

|

|

A lot of work was simple, for example, oiling parts and taping the different sheets of the body. However, other work demanded a lot of brainstorming. Particularly, the body of Aiming 3 made a fiberglass needed urgent repairs and a simple but safe way to connect the hood and the bottom frame of the car. The body of Aiming 2 as well, made of plastic sheets, was difficult to design because of the aerodynamic shape of the car.

Everybody was working more or less together, such as, sometimes there would not much work to do. There was no real coordination, and this I guess is a characteristic of any club. Nevertheless, the work was getting done and we were ready for October 4 just on time.

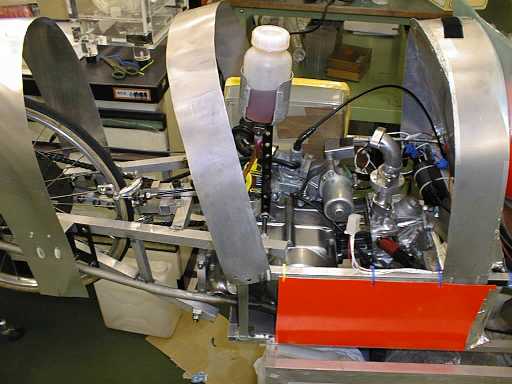

To the right: is Enya and Yamamoto working together on Aiming 3. This picture was taken a week before the event. Things had to speed up fairly rapidly around that time. Note the engine is wide open and connected to the different electronic devices and the battery.

|

|

|