The roller table is installed under the balance wheel against the hub using the staking set. If the roller is a single roller, you must select a hole punch with a notch on the side for the roller jewel. This watch has a double roller, however. You must align the roller jewel with the marking you made on the balance wheel earlier. After staking on the roller table, you must check the poise (weight distribution) of the balance assembly, without the hairspring:

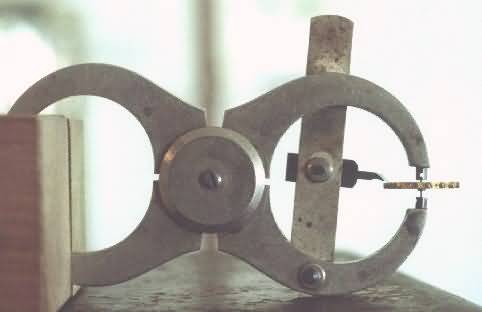

The poising tool must be absolutely level for this test. This poising tool has a bubble level built into it, which makes leveling it easy. If the balance wheel were out of poise, the heavier side would consistently rotate to the low side because of gravity. Weight could be added or removed by using timing washers or by undercutting one or more screws on the balance rim. Note that while you want to alter the weight distribution to poise the balance, you do not want to alter of overall weight of the balance or you would experience timekeeping problems.

Mount the hairspring onto the balance by pushing the hairspring collet onto the staff, using a flat-faced hole punch and the staking block (to keep the punch in a vertical position). The watch must be cleaned, repaired, assembled and lubricated prior to testing on the timing machine. Here is a photo of the watch with all the gears and other parts, but without the pillar plates, in order to show the gear train:

Please note that this essay is intended to introduce readers to a method for replacing a balance staff for a pocket watch or clock. This essay is not an adequate substitute for proper instruction from a qualified watchmaker. In other words, you could not go out and successfully replace a staff by just reading this essay: you must have appropriate instruction and guidance from an experienced watchmaker looking over your shoulder as you learn. There is no substitute for experience, just as there is no substitute for proper instruction.

Clock Repair Main Page

Escapements in Motion

Links Page

Tributes Page