|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Final Installations

|

|

|

|

|

|

|

|

|

|

|

|

|

I am assuming that you have reached this step after achieving the proper wear

pattern and backlash previously. As a result, the pinion bearing should

already

be installed onto the pinion gear with shim between the head and the bearing

and the carrier shims already selected.

|

|

|

|

|

|

|

|

|

|

|

|

|

- Slip the crush sleeve over the pinion gear.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The crush sleeve placed on the pinion gear. Notice the splines on the

top of the gear.

|

|

|

|

|

|

|

|

|

|

- Slide the pinion gear through the housing from the rear. Install the pinion yoke over the end of

the pinion gear.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sliding the yoke over the splined end of the pinion gear.

|

|

|

|

|

|

|

|

|

|

During your initial installation of the pinion gear you should have "practiced" setting the bearing preload

so this should be easy the second time

around.

|

|

|

|

|

|

|

|

- Install the pinion nut on the end of the pinion gear and slowly tighten it down until it is hand tight. At

this point there should still be front to rear

play in the pinion bearing.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tightening down the pinion nut. Notice that in order to keep

the pinion and yoke from spinning with the turns of the pinion

nut.

|

|

|

|

|

|

|

|

|

|

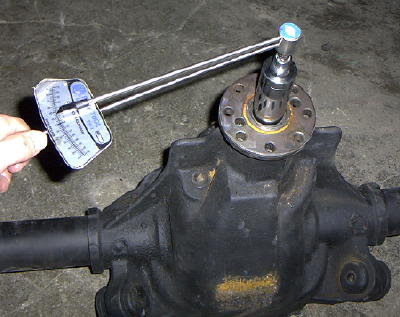

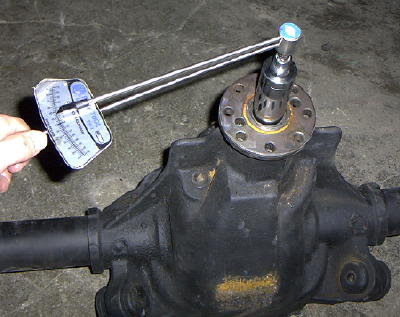

- Slowly turn the pinion nut which should be fairly hard to tighten because to tighten is to compress

the crush sleeve. The torque necessary should be

well over 100 ft./lbs. Turn the pinion nut about

1/8 of a turn, then use your torque wrench to check the bearing preload as was done previously.

Continue to

alternate between a 1/8 turn and a check of the bearing preload until a reading of 10

- 14 in./lbs. (if reusing old pinion bearings) or 18 - 28 in./lbs. (if using new

pinion bearings) is reached.

|

|

|

|

|

|

|

|

|

|

|

|

Do this very slowly and very carefully because if you reach a preload over the spec. you should not loosen

the pinion nut to reduce the preload. Once you go

over the spec. you must use a new crush sleeve (which

will be a pain in the ass if you don't have another handy.) You must sneak up on the bearing preload

specification.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Using the 1/4" torque wrench to read bearing preload. It

is not very noticeable from the picture but the in./lb. torque

wrench is 1/4" drive and the

pinion nut commands using

a socket which is 1 1/16". This socket is 1/2" drive. I needed

two adaptors: one to go from 1/4" to 3/8" and the second

to go from 3/8" to

1/2".

|

|

|

|

|

|

|

|

- Next install the carrier into the housing. Start by applying a small amount of gear lube to the carrier

bearings. The best order to proceed from my

perspective is to first place the carrier into the housing

with carrier races on the ends but without carrier shims. Then, on each side, slide the thinnest shims

in

place (as these cannot be tapped into place because they are too thin.) Finally, install the largest

shims on each side tapping them into place when

necessary.

|

|

|

|

|

|

|

|

- Install the bearing caps and bolts on the same sides they were removed from during disassembly.

Torque the bolts down to 85 ft./lbs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

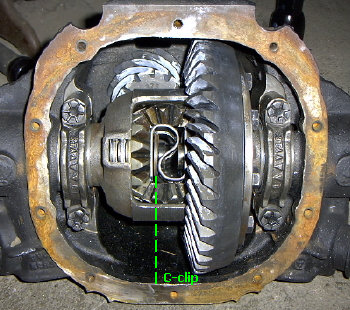

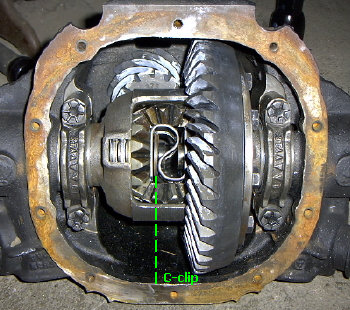

- Slide the axles into the axle tubes and through the splined side gears of the differential. Using a magnet

or needle nosed pliers install the C-clips

on the end of the axles. Then, push the axles outward to their

final resting place.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Look directly into the middle of the differential and

you will see the S-spring. The axle has been pushed

into the housing and on the end you can see that

the

C-clip has been slid onto it.

|

|

|

|

|

|

|

|

|

|

|

- Slide the pinion shaft bolt through the pinion gears. Install the pinion shaft retaining bolt and torque

to 333333333.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Push the pinion shaft retaining bolt through the pinion

gears. In the picture there is gear marking compound

on the ring and pinion: AT THIS POINT YOU

SHOULD HAVE

ALREADY CLEANED OFF THE GEAR MARKING COMPOUND.

(this picture was taken out of sequence.)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Install the pinion shaft retaining bolt.

|

|

|

|

|

|

|

- The final step is to install the cover. Your choice is to either use a gasket or RTV gasket maker. My gasket

came with the Ratech kit but looked to be

little more than a piece of a brown paper bag that was cut to

fit. I decided to use both the gasket and RTV.

|

|

|

|

|

- Using a 3/8" drive extension and ratchet remove the gear oil fill plug. Fill the rear with friction modifier

and three quarts of gear oil. Reinstall

the fill plug.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Back to Contents

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Next

|