| Center Section Disassembly | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In the photo to the left I only have 2 cover bolts installed. I took the photo in about the middle of the install, but obviously you know where to find the other eight bolts. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

I started at the top and worked my way down hoping the fluid would drain neater but it did not work.

The way to do this so you are the neatest would be to take

all bolts off except for the very top bolt. The

cover should still be sealed against the housing. Then just pry out on the bottom of the housing and

the fluid

will come out the bottom. Take a good look at the fluid's condition as it drains. (I bought the rear end that I rebuilt used and the fluid looked like mud.) I think it just makes sense that if the fluid is in bad condition, you may want to replace all of the bearings (on the carrier, the pinion, and in the axle tubes.) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Remove the pinion shaft retaining bolt. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| One side note right here is that the pinion shaft retaining bolt can break off and still be inside the pinion shaft, which will hold the pinion shaft in place. I didn't hit this roadblock, luckily. Just use some care when you loosen the retaining bolt. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Notice my pinion shaft retaining bolt was badly bent vs. the new one on the bottom. I just barely lucked out on this one. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Slide out the pinion shaft from the carrier. I've heard that the shaft slides right out, but in my case it did not. If it does slide right out and is not stuck, just push the shaft in about ½", then rotate the carrier and pull it out the other side. It may be a good idea to push in on the side that does not have a hole for the pinion shaft retaining bolt, this way you can use a hook or an awl in that hole to pull out with. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Push the pinion shaft in partway, rotate the differential housing, then remove the pinion shaft. You can use a pick or an awl by placing it through the retaining bolt hole and pulling out. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| My pinion shaft was stuck in the carrier and I had to pound it out with a large punch and small sledgehammer. I had to hit this thing very, very hard. Once I had it part way out I could not rotate the carrier because the shaft was hitting the back of the housing. I then had to break off the S-spring, push the axles inward, and remove the C-clips. After removing the axle shafts I rotated the carrier out of the housing. With it out and the room to punch the shaft all the way out I hammered it out. Hopefully that shaft will slide right out. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| On the left is the pinion shaft I removed from the rear end. Notice how it is dinged up around the top and bottom. On the right is a new pinion shaft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

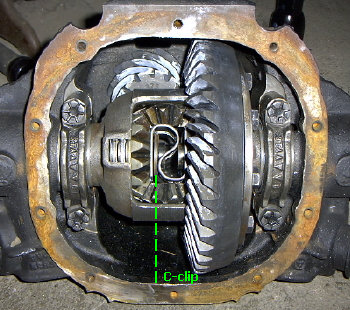

| Out at the end of the axle tubes; push in on the axles toward the center of the housing. Once you do this you'll be able to look inside the carrier and see the C-clips attached on the inside end of the axles. Remove these C-clips (by hand, with a magnet, or with needle nosed pliers,) which will allow you to remove the axles from the assembly. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Reach in with a pair of needle nose pliers or a magnet and remove the C-clip. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| I think all you should need to do is tap it lightly with a hammer which should pop it right out. You could also use a pry bar and GENTLY pry it out. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

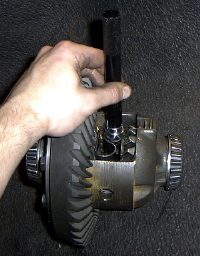

| The pictures that I have taken regarding the actual disassembly of the differential show the disassembly with the carrier out of the housing and on my work bench. I did take the carrier out first, then disassemble the Traction Lok and you may do the same. However I did have some trouble steadying the carrier on the bench and if I had it to do over I would have tried to disassemble the differential while it was still in the axle housing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| To get the S-spring out of the carrier I used a bearing bushing driver and a hammer to tap it out. If you don't have a bearing and bushing driver kit you can use just about anything to drive the spring out. Just be carefull that the side and pinion gears do not get the impact of your blows. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Once the S-spring has been driven out part way it will catch on the ring gear. I used a pry bar to prop it up over the ring gear and lightly tapped the S-spring from behind. A few light taps later the S-spring popped right out of the carrier. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| As I rotated the side gear the pinion gears started to rotate right out of the housing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Once rotated to the point where the pinion gears could be removed I pulled them out with my hand. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| With the pinion gears out of the housing the side gears will fall down toward the center of the housing. Remove them and all clutch discs. Keep track of which side the pieces have come off from. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| It may be a good idea to buy a set of metal stamps so that you can mark "left" and "right." I got a set from Harbor Freight Tools for five dollars, which you can't beat. It would be fine if you used a small punch and made one punch for left and two for right, or you could just set them on the ground on the side that they are removed from. Just do whatever it takes to keep the caps and side gears so that when you put them in they go in on the sides they were removed from. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Page 2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||