In 1957 the US Navy requested industry responses for the design of a low-altitude strike fighter. John Stack of NASA Langely briefed senior Navy managers that a proposed British low-altitude strike fighter, the NA-39, would be much more advanced than the Navy aircraft. He also suggested the application of variable sweep to leapfrog the capabilities of the NA-39. Following briefings by Langley personnel to the Navy, the mission specifications for the new Navy fighter were expanded to include multimission capability with a requirement that variable-sweep applications be studied. The request for proposals went to industry in early December 1959 and set the stage for what would ultimately become the Tactical Fighter Experimental (TFX) Program.

Meanwhile, the Air Force Tactical Air Command (TAC) Requirements Division at Langley Air Force Base (adjacent to the NASA Langley Research Center) was attempting to define a replacement for the F-105 fighter-bomber aircraft. TAC was interested in an aircraft that could carry nuclear weapons internally, fly transatlantic routes without refueling, operate from semiprepared fields in Europe, have a top speed of Mach number of 2.5 at high altitudes, and fly at high subsonic speeds at low altitudes. The aircraft would perform a “low-low-high” mission, wherein it would cruise into the vicinity of the target at low altitudes and subsonic speeds, perform a low-altitude dash to the target at high subsonic speeds, and perform a high-altitude, long-range cruise back to base at subsonic speeds. The Mach number of 2.5 capability would be used for high-altitude engagements against enemy fighters. Initial analysis by industry of the request indicated that a fixed-sweep aircraft capable of meeting the requirements would weigh in excess of 100,000 lb (too heavy for unprepared fields) and demand the attributes of low sweep for transatlantic flight, but high sweep for the high-speed requirements. TAC was therefore in a stalemate without a viable design approach to its requirements. John Stack approached the TAC planners in 1959 with the benefits of variable sweep to enable an aircraft to meet the requirements. The extended ferry range that is provided by variable sweep was of prime importance to TAC, since estimates indicated that transat-lantic range might be possible. Together with the commander of TAC, Stack laid out a realistic set of aircraft performance requirements that included the desired low-altitude dash capability at high subsonic speeds. Unfortunately, as the requirements went through the TAC system for approval, the final specifications called for a 210-n-mi, sea level dash at a speed that had increased from a Mach number of 0.9 to a Mach number of 1.2. Upon learning of the supersonic low-altitude speed requirement, NASA Langley quickly informed the Air Force that this capability was impossible to meet for the range specified. Nonetheless, TAC was committed to the unrealistic specification. (In flight tests of the F-111A in 1969, the actual low-altitude supersonic dash performance of the aircraft was only 30 n mi.)

In 1961, Secretary of Defense Robert S. McNamara initiated the Tactical Fighter Experimental (TFX) program for the US Navy and Air Force. McNamara believed that Navy and Air Force requirements for a new tactical fighter could best be met by development of a common aircraft. McNamara defined the basic mission requirements when the Air Force and Navy could not agree, and in October 1961, a request for proposals (RFP) was issued to industry.

In 1961, Secretary of Defense Robert S. McNamara initiated the Tactical Fighter Experimental (TFX) program for the US Navy and Air Force. McNamara believed that Navy and Air Force requirements for a new tactical fighter could best be met by development of a common aircraft. McNamara defined the basic mission requirements when the Air Force and Navy could not agree, and in October 1961, a request for proposals (RFP) was issued to industry.

Boeing won all four stages of the competition that followed, but McNamara overruled the source selection board. After extensive study of the recommendations of a joint Air Force-Navy evaluation board, McNamara decreed on 24 November 1962, that the General Dynamics and Grumman Team would build the TFX. In 1963, political turmoil surfaced as a special Senate subcommittee chaired by Senator McClellan of Arkansas held hearings on the award of the TFX Program. The decision, based on cost-effectiveness and efficiency considerations, irritated the chief of naval operations and the Air Force chief of staff, both of whom preferred separate new fighters for their services and Boeing as the contractor. Under the new management policies of Defense Secretary Robert McNamara and the "flexible response" military strategy of Joint Chiefs of Staff chairman Gen Maxwell D. Taylor, Air Force Chielf of Staff Curtis E. LeMay found himself at constant odds. In his four years as chief, LeMay argued strenuously for new air weapons like the Skybolt missile and B-70 bomber, and against the swingwing "fighter" plane, the General Dynamics TFX. He lost all these battles.

As a result of a poorly thought-out development specification, both the Navy and Air Force had become committed, much against their will, to the civilian-inspired TFX program. The program was designed to save $1 billion in development costs by using a common airframe to fulfill the Navy's fleet air-defense fighter requirement and the Air Force's long range nuclear and conventional tactical fighter requirement. In retrospect, this was impossible to achieve, especially since planners placed priority upon the Air Force requirement, and then tried to tailor this heavy landplane to the constraints of carrier-based naval operations.

On December 19, 1962, representatives of General Dynamics and Grumman visited NASA Langley for discussions of the supersonic performance of the F-111. The manufacturers were informed that the supersonic trim drag of the aircraft could be significantly reduced and maneuverability increased by selecting a more favorable outboard wing-pivot location. Unfortunately, the manufacturers did not act on this recommendation, and it was subsequently widely recognized that the F-111 wing pivots were too far inboard. (It should be noted that the F-14 designers, aware of this shortcoming, designed the F-14 with a more outboard pivot location.) The F-111 subsequently exhibited very high levels of trim drag at supersonic speeds during its operational lifetime.

The first F-111A flew in December 1964, and the first F-111B flew in May 1965. The most positive result from early flight evaluations was the very satisfactory behavior of the variable-sweep wing system. However, the aircraft were judged to be sluggish and underpowered. Furthermore, the engines exhibited violent stalling and surging characteristics.

The first F-111A flew in December 1964, and the first F-111B flew in May 1965. The most positive result from early flight evaluations was the very satisfactory behavior of the variable-sweep wing system. However, the aircraft were judged to be sluggish and underpowered. Furthermore, the engines exhibited violent stalling and surging characteristics.

As concern over the aerodynamic performance of the F-111 increased in 1964, it was also suggested that the wing with the longer span of the Navy aircraft be used on the Air Force aircraft. During 1965 Grumman discussed methods of improving the acceleration and maneuverability of the Navy F-111B. Modifications considered by Grumman included modified wing and pivot location, a straightened tailpipe, and an improved interengine fairing. In addition, Grumman examined a modified horizontal tail, alternate missile arrangements, and an aft-fuselage modification. Although these modifications never came to fruition for the F-111B, the discussions had a large impact on the later design of the F-14 by Grumman, which became an outstanding Navy aircraft.

Unfortunately, the naval F-111B configuration was too long to met the requirements for aircraft carrier elevator spotting (compatibility of the aircraft dimensions with the elevator on the aircraft carrier that transports aircraft to and from the flight deck and the lower hangar area).

The early F-111A exhibited numerous engine problems, including compressor surge and stalls. NASA was a participant in finding solutions to these problems, as its pilots and engineers flew test flights of the aircraft to determine inlet pressure fluctuations (dynamics) that led to these events. Eventually, as a result of NASA, Air Force, and General Dynamics studies, the engine problems were solved by a major inlet redesign.

Because of high cost overruns, trouble in meeting performance objectives, flight test crashes, and difficulties in adapting the plane to Navy use, the TFX's future became more and more uncertain. In 1968, the Navy TFX program was canceled due to the test aircraft's poor performance and incompatibility with carrier operations. After 1968, the Air Force was left with a TFX design that was compromised by McNamara's original commonality requirement. Ultimately, the Air Force fielded the TFX as different variants of the F-111 at five times the planned unit cost per airframe. The aircraft never developed all the performance capabilities proposed in the original program. The problems with the TFX can be directly attributed to the restrictions and requirements imposed by the common development program. Some of McNamara's critics in the services and Congress labeled the TFX a failure, but versions of the F-111 remained in Air Force service two decades after McNamara decided to produce them.

Because of high cost overruns, trouble in meeting performance objectives, flight test crashes, and difficulties in adapting the plane to Navy use, the TFX's future became more and more uncertain. In 1968, the Navy TFX program was canceled due to the test aircraft's poor performance and incompatibility with carrier operations. After 1968, the Air Force was left with a TFX design that was compromised by McNamara's original commonality requirement. Ultimately, the Air Force fielded the TFX as different variants of the F-111 at five times the planned unit cost per airframe. The aircraft never developed all the performance capabilities proposed in the original program. The problems with the TFX can be directly attributed to the restrictions and requirements imposed by the common development program. Some of McNamara's critics in the services and Congress labeled the TFX a failure, but versions of the F-111 remained in Air Force service two decades after McNamara decided to produce them.

By far the most sophisticated design of its time, the F-111 pushed the state of the art and, in doing so, it opened up a Pandora's box of surprises. For example, integrating all of those new little black boxes, in a "fly-fix-fly" fashion, proved to be an extremely laborious and, more important, time-consuming process. And this was only one of many problems encountered in the program.

As F-111 operations expanded within the Air Force in the late 1960’s, a rash of incidents involving unexpected departures from controlled flight during maneuvers at high angles of attack occurred. The F-111 had been designed with a g-command flight control system that provided g-forces in direct pro-portion to the deflection of the pilot control stick. However, in providing the pilot with the level of g-force, the system would increase the angle of attack of the aircraft. Unless the pilot was monitoring the angle of attack, the aircraft could enter a range of high angles of attack where a loss of directional stability resulted in an unintentional yaw departure and spin entry. These findings led to an Air Force program in 1973 to develop a stall inhibitor system (SIS) for the F-111. Several F-111 aircraft were lost in spin accidents during fleet operations; however, the subsequent implementation of the SIS prevented stalls and eliminated spins as an operational concern.

The F-111 airframe utilized a significant amount of high-strength D6ac steel in the wing carry-through structure. This component was heat treated to a tensile strength of 220,000 psi and designed for -3g to 7.33g with design flight life goals of 4,000 hr and 10 years of service. However, a full-scale static test program that was conducted over a 6-year period encountered several failures, including a failure at the wing-pivot fitting. Various modifications, including the first use of an advanced boron-reinforced composite doubler to reduce stress levels, coupled with an extension of the structural tests to 40,000 hr, were believed to have provided for 10,000 hr of safe operations. In December 1969, an F-111 experienced a catastrophic wing failure during a pull-up from a simulated bombing run at Nellis Air Force Base. This aircraft only had about 100 hr of flight time when the wing failed. The failure originated from a fatigue crack, which had emanated from a sharp-edged forging defect in the wing-pivot fitting. As a result of the accident, the Air Force convened several special committees to investigate the failure and recommend a recovery program. The original material had low fracture toughness due to the heat-treatment process. The heat-treatment process was corrected to provide improved toughness for the D6ac material.

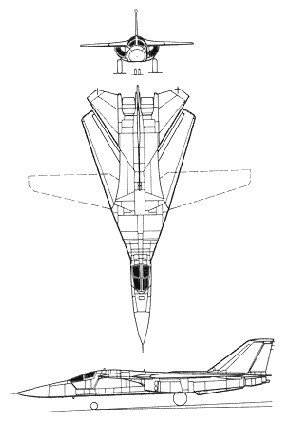

Manufacturer: Grumman/General Dynamics (now Lockheed Martin)

Manufacturer: Grumman/General Dynamics (now Lockheed Martin)

Powerplant: Two Pratt & Whitney TF30-100/111/111+ afterburning turbofans

Thrust: 50,200 lb (223.3 kN) with afterburner

Length: 73.50 ft (22.40 m)

Wingspan unswept: 63.00 ft (19.20 m)

Wingspan swept: 31.96 ft (9.74 m)

Height: 17.12 ft (5.22 m)

Wing Area: 525 ft (48.79 m)

Weight empty: 47,481 lb (21,537 kg)

Max. takeoff: 100,000 lb (45,360 kg)

Fuel capacity: unknown

Max. payload: 31,500 lb (14,228 kg)