PUBLICATIONS : P C Adkins & K P Adkins

Publications

Pat Adkins' obituary

Pat Adkins' Saxon iron smelting site excavation

Birch Airfield - by Neil Cowling

ARCHAEOLOGY NORTH OF THE RIVER BLACKWATER

Introduction

The river Blackwater is in mid Essex, England UK. The Blackwater starts as a small spring fed stream (known by its early name the river Pant) meandering some 25 km towards the North Sea coast. Many tiny tributaries help to slowly increase its volume to that of a small freshwater river. It is joined by the river Chelmer, changing from fresh to saline before reaching the town of Maldon. The river widens vastly and continues a further few km to its estuary. This tidal part is the subject of my archaeological excavations.

It is difficult to imagine our early ancestors settling by the river Blackwater without taking advantage of the hill where now stands the town of Maldon. Archaeologists, in particular members of the Maldon Archaeological Group have worked diligently to piece together the jigsaw of the town’s origins.

Evidence gained from excavations and aerial photography indicates that the site of Maldon has been a major settlement over many millennia. If one accepts that Maldon has always been the predominant settlement along the river one would expect to find from either excavation or survey, evidence of supporting settlements, farmsteads and industries in the surrounding area together with inter- linking track ways, roads and trade routs.

Since 1981 I have excavated a number of sites along the North Bank of the river Blackwater. Much of this work remains to be published. However, this summary with reference to already published material will hopefully give the reader a useful indication of the archaeology of the area.

My own background is in general building, boat building and fire fighting. My first job was as a Woodman’s assistant on the Birch Hall estate. It was this experience together with growing up in a very rural part of the county which probably helped me to understand how man was able to work in harmony with nature. For example using the sustainable practices of hedge laying, coppicing, charcoal making etc.

I have been able to call upon this first-hand experience in interpreting the archaeology from my excavations.

The prehistoric environment

The North bank of the river Blackwater is formed mainly of Boulder Clay lightly covered with layers of `Maldon Till’ and/or Blue London clay. The gravel terraces were formed from glacial out wash of successive ice ages. Carried within the huge glaciers, ground rocks pushed down from the north to as far as Tiptree. As the ice retreated out-wash transported gravels which built up along the banks of the river. Following the last few ice ages melt water deposited fine silts across the plains of Totham covering the gravels sloping away from the terrace. This overburden layer of deposits is known as brick-earth. Brick-earth is a rich soil for agriculture. It has also been used for the making of pottery since prehistoric times. After the ice receded these free-draining gravel terraces became ideal places for man to settle.

Evidence from recent archaeological excavations indicates that in prehistoric times the valley topography was of lush marsh land rising onto free draining gravel terraces before opening out to the lightly wooded plain beyond. Fresh water spring-fed tributaries ran into the saline estuary.

Multi-period occupation sites are abundant along the valley and the life style of the people dwelling there in could have been a relatively relaxed one. This now fertile valley would produce sufficient food for a very high populace. Fish, salt, kelp and shellfish would have been harvested from the sea. Wild fowl, small animals and samphire from the marshes. The plains could have provided larger animals and birds as well as fruit, honey and grass cereals. There would have been ample timber and reeds for building. There was also local flint for tools and weapons.

There was ample opportunity to trade along the saline rivers and waterways around the Blackwater. It is almost certain that this area played a major role in early continental trade with larger vessels unloading their wares at small ports on both banks of the saline part of the river and as far inland as Maldon and Heybridge.

There would have the opportunity to transfer cargoes of metals such as bronze, silver etc. and ores of lead, copper and iron to smaller vessels which could navigate further inland to wharfs or landing stages at places such as Beighliegh, Tollesbury, Salcot and possibly up the river Chelmer to Chelmsford.

Aerial photography shows evidence of inland trade in the form of ancient trackways visible as cropmarks reaching out along the valley. The tracks would have served many puroses for example as drove ways, salt routes and track ways from the forested areas to settlements for transporting timber for building, wood fuel for fires and charcoal for kilns, smithing hearths and smelting furnaces.

Many of the early track ways could well have been routes used by smelters and smiths serving local communities. A travelling Bronze Smith would visit each settlement in rotation setting up his forge and building temporary furnaces in order to melt bronze to cast into new tools, weapons or implements

He may have bartered his produce in exchange for local commodities (grain, fish, meat, pottery, skins etc). The smith would also have part exchanged new for old broken or worn out bronze tools. He was likely to have obtained the pack mules he used for carrying his stock of metals and equipment by bartering with the local people. In the event of having too heavy a stock of broken bronze implements or ingots the Bronze Smith would hide the surplus by burying it in "hoards" in an easily recognisable spot so that he could pick it up the next time he visited the area. This way he could travel lighter to the next village.

Bronze Age Smiths Hoards including a copper ingot hoard have been found along the valley. At Rook Hall a hoard was found close to a henge? / ring ditch. One small pit contained a fragment of bronze socketed axe in the midst of probable funeral vessels and cremated bone. A well of the same period was found nearby.

A section through a timber post/ladder found at the base of the well has been dated by dendrochronology to 900 BC.

This ties in with the pottery and bronze implements found in features on the site.

Iron was produced locally from as early as the Roman period. Furnace remains have been found on sites at Chapel Farm and Rook Hall Farm. Further evidence of iron working has been found at Little Totham and at Broad Street Green in the form of smithies forges and foundries.

In more recent times the foundries of the `Maldon Iron Works’ moved the three miles from their original site at Broad Street Green to benefit from the railway to Witham when it was first constructed.

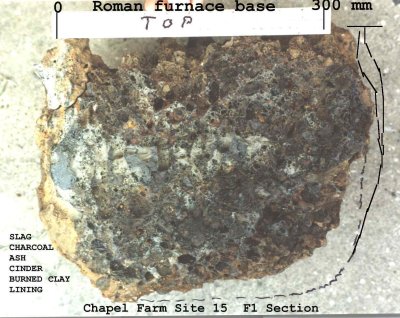

At Chapel Farm evidence of Roman iron smelting was found in the form of the total "residue base" of a small sunken pit furnace. Charcoal extracted from the residue had an RC date of around 250 AD.

Site 2 Rook Hall produced evidence of a large scale iron working industry. TL and RC dating confirmed an early Saxon date around 600 AD.

Several types of furnace were recorded as were smithing hearths Finds included furnace debris, roasted ore charcoal and a metal object from within one of the smiths hearths.

The production of salt at "Red Hills" along the river would have supplied inland communities, villages and `towns’.

From aerial photography and on ground excavation a very straight ancient `metalled road at Heybridge has been traced a distance of some 7 km across fields at Lofts Farm, Slough House Farm, Rook Hall Farm and Chapel Farm towards a cluster of Red Hills at Salcot. This could well have been one of the major `Salt Routes’ for collection and distribution to inland settlements.

An offshoot from the production of salt is that the very high temperatures sometimes achieved from the evaporation process resulted in the formation of a crude `Salt glazing’ type of material from which delicate ceramic artefacts could be made. It is common to find `chunks’ up to 130mm dia. in excavations along the river

A tiny Saxon bead believed to be made from such material was found during excavations along the valley.

Charcoal was the main fuel and reducing agent used in furnaces for smelting iron, bronze or any other metals. As the demand for iron grew, furnaces became larger and used enormous quantities of fuel. It would have been impossible for the furnace men and smiths to make their own charcoal on such a large scale and charcoal making became a separate industry .In the Black Forest in Germany during the early 15th century a single Medieval ironworks would require 500 wagons of charcoal annually. It is estimated that 48 wagons of good Beech wood is required to produce 6 wagons of charcoal per pile (one kilning) This meant felling around 125 hectares of Beech forest each year. The trees had to be at least 20 years old to produce good quality charcoal needed for the furnaces.

Charcoal was used in large quantities as fuel for the maltings and oast houses. The charcoal makers supplying fuel for these premises were known as "Reevers" and at Malting Green, in the nearby village of Layer De La Haye, The cottage near the Maltings building in Field Farm Lane is still known as "Reeves" cottage.

Site 2. Rook Hall, Little Totham. (1982-89)

Mid-East Essex, Approximately two kilometres north of the wider portion of the saline head of the river Blackwater. TL 878093

It lies on the level known locally as the Totham Plains and is part of Rook Hall farm. Being only one or two meters above sea level the site has always been vulnerable to flooding and this may have created conditions such that it was necessary for the local population to move to higher ground during some of these tidal surges.

The earliest evidence of animal activity is what appears to be the tusk of a wild boar preserved in the moist gravel conditions approximately 3 metres below the present surface.

Mesolithic

Located on one particular part of the site was a large collection of raw flint nodules or irregular shaped stones approximately 120mm dia.

Stratified crudely napped pebble tools were found during excavation of the `work surfaces’ in the early occupation levels.

There is much evidence of human occupation over the site since early pre historic times. Neolithic features containing finds of more skilfully worked flint and pot sherds were recorded in three separate occupation areas.

Bronze Age

From the earliest Bronze age through to middle Iron Age the local people were very active on the site. Excavations on the site revealed evidence of;- Enclosures, Dwellings, Well’s, Kilns, Pottery, Worked flint, Metal tools, Cremations and features in the form of a possible Henge with nearby pits containing funereal vessels and a fragment of bronze socketed axe thatcould have had ritual significance.

Iron Age

Large number of early Iron age features were recognised and many pottery finds made. Later Iron Age and Early Roman occupation was less evident with few finds of local hand made and imported pottery in some features.

Roman

The site was probably used for agriculture during the main Roman period as only the odd sherd of pot or scrap of Tegula and brick were discovered there. Two long straight and narrow ditches could well have been connected with the Roman agricultural allotment system known as "centuriation"

Saxon

The Saxons certainly occupied sites on both sides of the river Blackwater. At the Rook Hall site evidence was found of domestic buildings and of large scale iron working from the Early Saxon period. The source of the raw iron ore has not yet been located but several samples of purple coloured semi-roasted ore were taken from features in the iron working area. There is some evidence of small scale charcoal making and storing on site but if the fuel for the furnaces was produced locally in charcoal pits it would have required an enormous amount of raw timber to be taken to the site and one would expect to have found evidence of well formed track ways to and from the forested areas.

On the other hand if the charcoal was being produced in or close to the forests only one eighth of the bulk (and less than one twentieth of the weight) would need to be transported and the remains of these track ways would be less obvious in modern day observation from the air.

Smithing hearths or forges were evident, some of which had layers of smithies scale around them, produced by metal sparks flying of the worked bloom. Only one actual iron object was found. This was one half of a pair of tongs probably used by the smith to handle the red hot bloom. The top `spring’ end loop appeared to be encased in clay which had been partly fired, possibly from the heat of the forge, or maybe as a deliberate form of insulation?.

Raw timber was used for domestic fires out of doors, Once well alight a mixture of the hot ashes and charred dry wood could be taken inside the timber and thatch houses for winter warmth, and for cooking purposes. Almost total crushed remains of four grass tempered domestic `Bag’ pots were found, One of which was still on the remains of the fire used to heat it and it’s contents. Raw timber was also used as a fuel to heat Domestic ovens and to fire Grain dryers and larger Pottery Kilns.

The features Site 2. Rook Hall

.Structures: Dwellings, and industrial buildings.

Round houses, Rectangular huts, Spiralled entranced huts, Four posted and multi-posted buildings (granaries ?), Sunken floored structures (Grubenhausen) Industrial huts Smithing foundries, Smelting/furnace -mans hut, Potters shed?. Henge? And Small Square "temple" or Mortuary House.

Wells, Watering Holes, Deep Pits and ponds etc.

Nine wells were found at Rook Hall Site. They varied in diameter and depth from 0.7m - 10.0m diam. and 1.8m - 3.9m depth.

Four were certainly used for water. Two contained `waste’ in the form of ash, broken pot & daub? The remaining three contained a mixture of clean clay and what appeared to be lime or chalk?. Bone was found in two of the wells. Some of the Wells were lined with interwoven panels.

A well ladder was excavated from one well (dated to 900BC). Stakes to support well linings (F661), were taken to County Archaeology Department for processing.Two parallel rows of small post holes spaced about one meter apart indicated there had been a posted "walk way" from a nearby road to the well.

The remaining pit features had been used for the purposes of drinking water, cooking, watering of animals and for industry pottery making, washing and dying of woven cloth and for quenching in the process of iron working. Furnace debris was found in many.

A vast number of uses were proposed for these features. Pits for underground storage of grain and other commodities, charcoal making and storing. Many were later used as middens etc. Crushed pottery mixed with clay was found in one pit close to a kiln.

Ditches, Dykes, Gullies and Drains

Apart from the obvious draining of land for agriculture these were used to help keep the surface dry under foot, or collecting water from springs and streams. Also for demarcating boundaries, enclosing stock and defensive purposes.

Clay and Gravel Quarries

For example, supplying the raw materials in the making of pottery & brick, for material for road building and repairs & searching for suitable flint to work into tools etc.

Fires, Kilns, Bonfire kilns, ovens, and corn dryers etc.

A very large number of features had been subjected to severe heat and most were easily identified for what purpose they had been used. The odd one or two were a little perplexing in that they had been used for several purposes such as bonfire kilning parallel with use as a pyre for cremations. The ashes then being collected and buried in small cremation pits, scores of which were found on the site.

Several features contained evidence of heat crackled flint used for tempering of pottery. Grog?, grass and grit were also used as a form of tempering.

There was also evidence of buildings suffering destruction by fire. It is not clear whether this was the result of accidental burning of buildings or sacking during invasions / battles.

Kiln finds

Kiln wasters, vessel handles, loom weights were recovered. Huge quantities of sherds of pottery decorated in various forms and types of design., finger tip, pinched, smoothed and burnished, or marked by implement. Square "biscuits" of perforated kiln furniture.

This feature may be the key to unlocking the answers to many questions relating to how the bonfire kiln developed towards the enclosed modern day kiln. The site having had the top soil removed earlier, had been exposed to the hot summer elements for about three months.

When I discovered F 1. all that was visible was a small area of brick red clay speckled with fragments of charcoal, charred twigs and ash showing through the pale orange brown parched natural clay.

On the advice of County Archaeologist David Buckley I attempted to remove a fine layer around the feature in order to expose its limits. This turned out to be too difficult due to the concrete like overburden and I abandoned the task until the weather changed.

After a period of heavy rain I returned to F 1. having by that time discovered and recorded a further dozen features.This time I was able to expose the limits of the obvious parts including the "stoke hole" , fire tunnel and kiln pit proper of the feature. Unfortunately, a heat wave again dried out the overburden and it became almost impossible to define the extent of the remainder of the feature for some time to come. Knowing that the site was in danger of being destroyed by quarrying I decided to excavate that part of the feature which was obvious to the eye. Where it became impossible to use a trowel I resorted to forking out as large a sample of cross-section as I could. These samples were bagged and labelled and transported home for later processing. This method turned out to be quite useful as some ten years later I was able to refresh my memory from time to time by inspecting the finds in my store. Some time later I was able to locate the full extent of the feature including two associated pits within the confines of the feature boundaries.

Apart from evidence of kiln failures in the form of wasters, broken or badly fired ceramics, there was also an area where clay had apparently been mixed with crushed pottery perhaps to make grog for tempering the clay prior to firing.

The main purpose of this feature was that of a well / watering hole in use from around the early bronze age period (1500 BC). It appears to have fallen into disuse during the middle to late Bronze age and after the collapse of the surrounding soil filling in the lower levels the remaining bowl shaped upper section was use as a watering hole with log steps leading down to the central deeper part. It later became a place for dumping of domestic rubbish until it was filled in around 1,000 BC.

The feature was then used for the purpose of both bonfire kiln and as a crematorium. There is evidence of several firings of bonfires / kilns over the nine meter diameter hollow by way of charcoal, ash, pottery burned clay and crushed pottery mixed with clay and "vegetation?" like material.

The small scatterings of burnt bone, charcoal and ash from the central "fire" seem to indicate that this feature had been used for at least one cremation and was probably a place of the ritual pyre prior to burial of many of the numerous cremations in small pits scattered over the site.

Jewellery

A "shale"? finger ring.

A decorated bronze strap end.

A tiny blue/green "glass" bead from a probable Saxon feature.

A fragment of entwined snake decorated bronze disk brooch.

A plain bronze buckle or strap end.

Weapons, Tools and Implements

These can be divided into categories of materials used.( Wood, Flint, Bronze and Iron).

Wood:

A Bow arrow shaft of hazel wood, Shafts for socked axe`s Wooden ladder into well, Posts and stakes for fencing etc.

Flint:

Flint spear heads, arrow tips, axes, skin scrapers. Borers, knives and blades, hammer heads and micro tools.

Bronze:

Three bronze age implement and weapon hoards were found in the vicinity. One hoard also contained approx 7 kg of copper ingots. Bronze socketed axe blades, Carps tongue swords, daggers and spear heads. Tools included chisels and gouges and one fragment of a lynch Pin.

Iron:

Few iron objects survived in the acid soil and salt air over the valley. It is probable also that being scarce most iron objects would have been recycled.

Professor M S Baxter Bsc Phd CChem FRSC

Radiocarbon Dating Laboratory Scottish Universities Research & Reactor Centre East Kilbride. Glasgow. G75OQU

GU-2151 Little Totham Site 2 Sample F1911 BP1380 +/- 60 s 13C = -24.71 % o

(Cal) AD 620 - 675 @ 68% confidence level

(Cal) AD 560 - 760 @ 95% confidence level. (7th Century Early Saxon.

Charcoal Species id by Rowena Gale (Maple & Oak) Interpretation by A J Clark Phd FSA Royal Arch; Institute 24th February 1987.Financed by Lloyd’s Bank Archaeological Awards 1986.

Janet Ambers.Research Laboratory. THE BRITISH MUSEUM London WC1 3DG. BM-2668 Little Totham Site Chapel Farm F1 BP1740 +/- 50 (Cal) AD 235 - 350 @ 1 sigma or

(Cal) AD 365 - 370 @ 68% confidence level

(Cal) AD 145 - 170 @ 2 sigma or

(Cal) AD 175 - 405 @ 95% confidence level.

2nd to 3rd Century AD ROMAN.

Calib dates in Mook (1986)

Result form in Stuiver & Polach (1977)

Control Material = Irish Oak

Charcoal sample = Oak

Financed by Historical Metallurgical Society.

Fragment of tuyere from F1911 Site 2 Rook Hall

Ian Bailiff. & Iain Watson TL Research Laboratory. University of Durham. DH1 3HP DUA

- TL 90 - 1AS 530 AD +/- 290 accuracy.

Financed by Historical Metallurgy Society.

Slice of Wood Post base from Well F2307 Rook Hall Site 2.

Miss Jennifer Hillam. FSA MIFA. & Miss C M Groves. Dendrochronology Laboratory. University of Sheffield. Tree ring sample - Span = 1264 - 1106 BC.

From large Oak. (Poss 10 sap rings missing) Tree was felled or died some time after 1096 BC Financed by British Archaeological Awards Scheme.

Analysis by Professor R T Tylecote. Institute of Metals. Oxford University.

Virgin Copper Hoard with two fragments of Implements. Dated to around Early Late Bronze Age Period.

Financed by Institute of Metals./ Hist Metlgy Society.

Recent discussion with Chris Salter reveals that the

hoards were actually worked on by himself on behalf of

Peter Northover although they were handled via Ronnie Tylecote.

SAXON IRON WORKING AT ROOK HALL, LITTLE TOTHAM. ESSEX.

Pat Adkins

A seven year archaeological watching brief combined with salvage/rescue excavations on a gravel extraction site at Rook Hall, Chigborough Road, Little Totham, Essex, (GR. TL /878092) has produced evidence for an extensive Early Saxon Iron Working Industry.

Remains of various types of smelting furnaces have been recorded.

Furnaces of the slag-tapping type from the main site have been dated (by radiocarbon and thermoluminescence) to the 7th century AD. Evidence was also obtained for the ancillary processes of charcoal making and ore roasting. Smithing hearths excavated within Grubenhaus type sunken floored buildings indicate that the iron was being worked on site.

The site lies approximately 1.5km from the north bank of the estuary of the river Blackwater. These gravel terraces generally provide conditions conducive to cropmark formation (Fig 2).

A number of sites originally discovered from cropmarks in recent years (Ref 1.) provide evidence for continuous occupation of the area from the Neolithic period (Fig 2.) to Saxon period. However, in the case of the Rook Hall site overburden with a high clay content minimised the effects of summer drought and cropmark development. Consequently no evidence for the intensive industrial activities was obtained until the plough soil had been removed in advance of gravel extraction.

A vigilant watching brief was maintained by Pat Adkins during topsoil stripping and gravel extraction.

Over a six year period (1982-1988) more than 3000 prehistoric features from 25 hectare site were recorded, many of which were of easily recognisable form eg. wells, enclosure ditches etc.

In the autumn of 1983 many fragments of iron slag were found during topsoil stripping. these were originally thought to have come from nearby Victorian iron works at Maldon. In the spring of 1984 the gravel company temporarily changed methods 0f removing the overburden from box-scrapers to hydraulic arm bucket grab type machines. These machines left a vertical `face' every 5m as they traversed the site. One such `face' cut through a large feature (see Fig 4) revealing large quantities of slag and furnace rubble in situ.

Again the iron slag was initially thought to have been dumped from the Maldon works , although the reasons for removing slag some 3km from the Victorian works were perplexing. On October 22nd 1985, after the gravel company reverted to using box-scrapers, features were uncovered which were to confirm that iron had been smelted on site. Fig 5 shows a section north-south .

By Friday 25th October an area of iron working features had been uncovered extending over 5,000 square meters. Throughout the next month new features relating to iron working were discovered almost every `turnaround'of the box scraper.

In order to record these features it was necessary for me to extend my working time to well over 15 hours each day including weekends when I was assisted by my son Kelvin.

With the co-operation from the gravel company opportunity was provided for advanced salvage excavations to be carried out over the main smelting area. Features from this area and a separate find of a furnace bottom from a neighbouring farm are discussed below.

A plan of the remains of the smelting furnaces and slag tapping pits can be seen (Fig 6) together with pits associated with ore pre-roasting and iron forging/smithing processes.

This feature (F1911) was sectioned in many places. This proved to be no mean task since successive layers of slag, cinder and rubble had fused together to form a very hard conglomerate

In (Fig7) can be seen phases of use of the furnaces -ie; latest phases = (C-D),(E-F),(L-M) and the upper levels of (H-I). All other sections shown are those recorded after each "cut" of the box scraper across points (H-I). This was done by quickly digging into the feature (one spit depth) across line H-I between each successive turnaround of the box-scraper.(A method too dangerous to recommend without full co-operation from the machine driver who in my case often obligingly diverted the machine to allow me to record the feature).

Figs 8(a,and b) illustrate details of F1911 across section (J-K). Fig 8a. illustrates two phases of the smelting furnaces (ie. superimposed furnace bottoms. While Fig 8b shows a section across part of the feature which appears to have been used as a dump-pit for furnace rubble or may possibly represent a furnace which had collapsed inwards. The pit then being reused for other purposes perhaps ore roasting. This would explain the lenses of orange-red baked clay and account for the large quantities of roast ore. The slag was of the usual high density bloomery type, some pieces measuring 0.29m X 0.23m X 0.07m thick with sharp edges clearly showing that they had been broken off even larger slabs. The pit contained large quantities of other furnace debris including vitrified porous furnace wall and bottom fragments, large lumps of cinder with unburnt charcoal, ore and ash fused together. Much loose charcoal, ash, and crushed smithing hearth debris was also present. Finds also included many fragments of clay tuyeres (some with slag and vitrified clay attached),and a few nodules of iron encased in thick rust and clay.

Below the base of this pit feature was found a layer of fine grey soil covering a lining of charcoal/black silt mixture. Maybe the remains of an earlier charcoal pit ?.

Charcoal from this area gave the following C-14 date:-607 +/- 60 AD (Ref.SUR&RC. GU-2151.)

TL.date of the Tuyere from the layer above 530 AD +/- 290 (Ref.DurTL 90-1AS.).

Underneath all this was a 0.35m thick layer of almost clean "stone- free" sand/clay mixture. It appeared the pit had originally been dug out of the overburden then refilled with approximately one foot (0.3m) of stone free soil before using it for whatever purpose. In Fig 8a. there appears to be the bases of two furnaces super-imposed one upon the other no doubt relating to different phases. The position of the tuyere (see Fig 10) and some of the iron nodules is shown and may be in their original positions. Whilst section J-K runs east-west across F1911, In Fig 9, can be seen another section (X-XX) which runs north-south across this feature. Hearth bottoms are clearly visible showing that several phases of smithing or similar activities had taken place. Again, the large quantity of roasted ore in the pit indicates pre-roasting was being carried out close by.

Professor R F Tylecote (Department of Archaeology London.Uni) kindly offered to examine finds from the site and his report and comments are published below. (Ref.RFT 1 and RFT 2)

RFT 1. Within one grubenhaus type hut feature (F2014) was found the remains of a large hearth used for smithing. The floor was covered with specks of rust "corroded iron scale" from the Smiths forge. There was one piece of iron in the form of a bar 10cm long encased in rust and clay. There were a large number of small "nodules" about 3 cm diam. which turned out to be pieces of high carbon iron encased in rust and clay. From the whole site the nodules found fell into two groups. Those from F2456 had a lower SG = 2.0 g/cc and seemed to be mostly iron pan. The second group from F2014 and F1911 had a higher density =2.6g/cc and after the clay-rust envelopes were removed were shown to be pieces of metal. Metallography showed one to be a piece of cast steel rapidly cooled with a columnar grain structure of pearlite with a little ferrite with hardness of 276 HV1. Slag was absent. These are probably "grompie" ie. pieces of highly reduced iron held in the upper levels of the smelting furnace and not oxidised like the bulk of the product lower down.

If the smith were making steel rather than iron it is possible for them to be pieces of steel knocked off the bloom but this is less likely.

The tuyeres (see Fig 10) were D-shaped in section with very straight bores. They had been prefabricated in "blocks" which had been inserted into the furnace as it was built. As the remains are relatively short we have little idea how far they went into the furnaces. The ends are slagged only a short distance and this would suggest that they were only inserted a short distance into the furnace. (RTF2 end)

600 metres to the east of the central area was found a single furnace bottom of a type familiar in Saxon migration context in Northern Europe (see Fig 11) This object was found in September 1987 when Farm worker Mr M Sayer, using a tractor towing mole-draining implement unearthed what was at first thought to be a huge `lump' of ironstone (pan). Farm manager Mr P Sayer informed Pat Adkins of the find and with permission from the Farmer Mr T Howe they rescued it from the farm rubble dump.

RFT 2. This is clearly a furnace bottom from an early iron smelting furnace . It measures 46 cm diam. and is 38cm high and has a weight of 66 kg after removal of loose fragments. While it appeared to be in its original position there were no signs of metallurgical activity around it merely a few fragments of slag, iron nails and a knapped flint.

This is unusual as these objects normally occur in `fields' as a result of smelting in which each furnace bottom represents the remains of one smelt of about 10 – 20 kg of rough iron. However, it does agree with that found by Mrs M Jones at Mucking near Tilbury, Essex.

These slag `lumps' form at the base of a shaft furnace where a pit is dug and the walls of the shaft are built up around it (Fig 12). The pit will be at first full of straw, chaff or charcoal while a good fire is got going in the shaft urged eventually by bellows directed through one or more tuyeres in the side. After the temperature of the fire has reached 1200 degrees C. ore and more charcoal are charged through the top for 6 hours or so in the right proportions. Slag and metal will form at the bottom below the tuyere. In order to seperate them, the fuel in the pit is burned out (according to the Poles, by blowing in air through an auxiliary tuyere directed into the pit.) This creates a void into which the slag can fall leaving the bloom of metal resting upon the solidified slag. We do not know whether the slag lumps represent more than one smelt, But it is clear that the shaft can be moved sideways like a chimney pot, over a new pit, and the whole operation started again. Sooner or later the shaft will need to be renewed completely. Such a system is now called the "slag-pit furnace" and seems to have been common in Northern Europe from the 2nd Century BC to the 8th Century AD. It has affinities with a type found in Nigeria and the Sahara originally of the same date but carried on into recent times. (RFT 2 End)

Tap slag

List of Illustrations (some to follow)

Fig 1.(a & b) Location maps.

Fig 2.Plan of local cropmarks from aerial photography.

Fig 3. Plan of Main Iron Working Features.

Fig 4. Section of Features F956 and F957.as seen in quarry face.

Fig 5. Section north - south across main area .All features contained evidence of iron working.

Fig 6. Plan of The Main Furnace, F1911. (Sections marked).

Fig 7. Superimposed sections of furnace F1911.

Fig 8. Detailed section (J-K) across furnace F1911. (east-west)

Fig 9. Detailed section (X-XX) across F1911. (north-south)

Fig 10. Illustration of tuyer from F1911.

Fig 11. Furnace from Chapel Farm, Lt Totham.

Fig 12. Impression of possible furnace types on the site.

Other sites along the Blackwater valley.

Site 8. Tolleshunt D’arcy.

This site is part of Hill Farm situated on a gravel mound on the north bank of the Blackwater valley approximately four kilometres east of the Rook Hall site.

Gravel extraction and the construction of an agricultural water reservoir gave opportunity to investigate the archaeology of this site and excavations were carried out under salvage rescue conditions. Bulldozers towing 35 cubic meter box scrapers were used to remove the top soil and a shallow layer of sub soil. This revealed most of the important features which were hastily plotted, drawn up and then partially excavated.

Features dated as far back as the Neolithic and Bronze age periods and many originated during the Late Iron age period. The majority of features were in use during the Early Roman period.

The predominant use of the excavated area was that of a Romano-British Farmstead. Features included round houses, ditched enclosures, granaries and a corn mill. Kilns were making domestic pottery and for vessels and furniture used in the production of salt at the "Red Hills" just one kilometre away by the waters edge.

Close to the corn mill was a pit containing approximately one cubic meter of charred grain.A large portion of grinding wheel dated to the early Roman period was located in a shallow trench which appeared to be part of the foundations of the mill.

One of the round houses had an additional entrance hall extending around the main doorway. There was evidence of a hearth within the building being used for kilning or for pre-heating pottery and ceramic implements such as spindle whorls, triangular loom weights and what appear to be pedestal feet perhaps part of pillars used to support the evaporating pans used in the extraction of salt from brine.

The detailed study of this round house with a hearth used for kilning or pre-heating clay objects gives an insight to the way of life at that time.

It appears that apart from the run of the mill domestic chores during the winter or in rough weather it is likely that the occupiers worked inside preparing the clay with tempering and making the various supplies of ceramics and kiln ware required for the coming year.

These could then be pre-heated on the indoor hearth and stored ready for the main kilning when the weather was suitable.

In some instances the hearth was of high enough temperature to actually fire the items placed upon it.

This reduced the need for further firing in the external kiln.

The main kiln.

A more sophisticated kiln was located near to the round house at Hill Farm, and this may have been the successor to the hearth kiln.

The clay kiln lining walls and the stoke hole tunnel had been strengthened using broken used fire bars and other broken kiln wall rubble placed at regular spacings.

It has been suggested that this feature was used for corn drying. There was certainly a corn mill nearby with evidence from a broken corn grinding wheel and burned corn in a large pit close to the mill.

As yet I have seen no evidence of perforated floor plates usually associated with corn drying ovens. In contrast there was ample evidence of broken pottery and wasters being dumped in the drainage ditch from the stoke hole.

It is possible the kiln was being used for both purposes. From observation of and assistance with the excavation it was obvious the kiln was empty in its final stage when it had collapsed inwards filling the lower levels with wall rubble, or had been deliberately destroyed dumping the rubble into the base of the kiln.

A single inverted pot was located centrally on the ground below the suspended floor of the kiln. This was probably used to support the fire bars.

There also is evidence at Hill farm site Tolleshunt Major of wooden and timber objects. Hurdles, windbreaks made from interwoven rush or hazel twigs, baskets, An interwoven Tray or Water well filter,? or maybe a well wall retainer.

Tollesbury.

This quiet riverside village was at one time reliant on the sea for its survival. It is situated on a peninsula at the Estuary where the river Blackwater meets the North Sea

A salt water creek running right up to the village was the life line to this Marine community.

There has long been suspected that a Roman Villa exists at Tollesbury. Some of the evidence coming from the finding of a quantity of small pavement tiles in the foundation trenches of a new building in North Road.

From the field belonging to Carringtons Farm, backing onto the houses in North Road Mr. Scot the farmer tells me that many sherds of Roman pottery have been identified.

Aerial photography by P C & K P Adkins during 1987 provided evidence of early activity in and around the same field and in a wider area multi-period occupation including a possible Roman Fortification or Marching Camp Between Bone Hall farm and Prentice Hall farm.

The site would have been a vantage point commanding a view over the North Bank of the River Blackwater Estuary. Other local strategically placed defences include the Roman fort at Bradwell on Sea on the opposite side of the river, defences of the same period at Mersea Island, and the Roman fortifications on both banks of the River Colne. This network would have defended any invasion from the North Sea and controled shipping up the river Colne to the Roman town of Colchester.

In the mid 1970`s, Whilst flying over the northern terraces of the river Kelvin and his father Pat photographed and recorded several complex crop mark sites. When they compared their results with black and white photographs of the same area taken a few years earlier on behalf of the Sites and Monuments Records Office they realised they had new evidence of additional crop marks spread along the valley. Again in 1980 they recorded new sites and during an on ground follow up visit to Chigborough Farm, Little Totham they were given the opportunity by the farmer Mr L P Sampson to survey and excavate one of the sites.

It is intended after processing is completed, to report the remaining sites and finds along the north bank of the river recorded by P C & K P Adkins ( Hopefully in future editions of CAG or MAG Bulletins). These include the Rookhall Excavations 1982-1989, Further reports on Hill Farm Tolleshunt D’arcy 1983 and some of the other minor excavations, Aerial archaeological surveys and Metal detecting / Field walking surveys.

From the results of these excavations an assessment has been made of the inhabitants way of life at the time of occupation.

Since writing the above introduction to the archaeology along the north bank of the river Blackwater, I (Patrick Adkins) have suffered a heart leaving me with heart conditions and more recently have been diagnosed as suffering from Mesothelioma (Cancer) which has effectively halted my work on archaeology.

A plea for help on the internet led to English Heritage contacting Essex County Archaeology department to offer to store the finds with a view to later publication of a report.

I have given all the finds from most of the sites and all the archive materials including 8 site books, plans and drawings of the sites, a very large quantity of notes, drawings, sketches and photographs etc. to be initially be stored at Colchester Museum stores.

This includes aproximately 7 tonnes of finds most of which are the contents of features involving iron working.

I have also given a copy of this introduction to my work together with scanned photos of the area and some of the features and finds from the sites , Also a file/folder containing detailed drawings notes and processing results of around the first 200 features (F1 to F200). from Rookhall Site 2.

Interim/summary reports of the excavations are recorded under the following titles .

"A Neolithic cooking pit at Chigborough Farm, Little Totham". Colchester Archaeological Group Bulletin. (CAG Bull) VOL. 27. p 33-44.

"Saxon loom weights and Roman Pottery from Chigborough Farm, Little Totham". CAG Bull; VOL. 28. p 44-56.

"A Neolithic settlement on the North Bank of the River Blackwater". CAG Bull; VOL. 34. p 15-28.

"Three Late Bronze Age Smiths’ Hoards" CAG Bull; VOL. 29 p27

" A Corn-grinding wheel from Tolleshunt D’arcy. CAG Bull; VOL 26. p13-16.

Essex Archaeology & History, Vol 18. 1987 107 - 108

Current Archaeology (1989) 115 Vol X, No 8, 262 - 263

Mr. Luke Sampson and Mr. D Western. Hill Farm.

Mr. and Mrs. French and family. Rook Hall.

Audrey and Charles Blick

Charles a professional expert on Ancient Metallurgy guided me along the correct path and put me in touch with all the right people. Without his help and the continuous help from bulldozer driver Robert Davies the whole task would have been almost impossible.

To members of Essex County Archaeology Section,

Especially, Nigel Brown, David Buckley, Susan Tyler, Deborah Priddy and the illustrators at the archaeology section.

Paul Brown, members of MAG and CAG who helped.

Peter Murphy, Peter Northover,

The Late Professor Ronald Tylecote gave me professional advice and expert interpretation of many of the features related to iron working.

Student Metallurgists at British Museum and Oxford University, Historical Metallurgy Society paid for T/L Dating of a Tuyere fragment.

Lloyd’s Bank who provided funds for dating of charcoal from the furnace.

Mr. Ian Bailiff - University of Durham (T/L Date)

Justine Bailey - The Historical Metallurgy Society Limited

Dr. S G E Bowman - British Museum, Jannet Ambers, Radio carbon dating charcoal from slag (F1 Chapel Farm)

Henry Clear, Rod Clough, Miss Effie Photos,

Prof M S Baxter East Kilbride -Glasgow University - C 14 dating charcoal F1911 Rook Hall.

Tony Clark - Royal Archaeological Institute

Jennifer Hillam - Dendrochronology - University of Sheffield.

Hall Aggregates (Eastern Counties) and staff. Mr. P Samms, Mr. D Boon, Mr. J Milner, Mr. D Day and Chris Dunn. Gowdey Bros and staff. In particular Robert Davis the bulldozer driver.

Mr. T Howe Chapel Farm, Paul Sayer, Paul Brown. James Fawn. Owen Bedwin.

To my son Kelvin for his academic skills and help on site and at home.

Last but not least my wife Betty for her understanding and tolerance of the muddy floors, cluttered rooms and late meals!

ILLUSTRATIONS TO FOLLOW

Email pcadkins@yahoo.com