The main thing I wanted to accomplish

at first was to get the power supply connected and tested out. I

did my first power-up without the tubes installed to see if my power

indicator light would come on, and it did (without smoke and bad

popping noises that let you know that you are probably finished with a

project such as this). I double-checked the connections to the

tube sockets and checked the filament voltages before installing the

tubes. I wanted to see that warm orange glow from the tube

filaments, so I popped them all in their sockets. The filament in

the power amp tube began to glow (see the out of focus picture) but the

pre-amp tubes did not have the same visible glow, but they did get

warm. I don't know if I should be able to see the filament in

those tubes, but I was satisfied that they did get warm at the

top. At the time I took these pictures I did not have any of the

signal lines connected to the tube sockets.

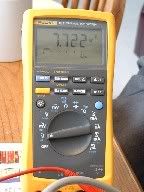

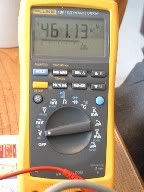

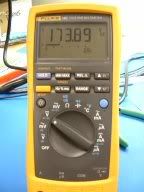

The power transformer has two outputs

on it. One is rated at 6.3V which powers the indicator lamp and

the filaments only. The other is a 190V output, but what is shown

on the meter below is the AC measurement between primary taps.

This is about the no-load AC range I expect. The no-load DC

measurement at the power supply filter output measures about

213V. So far it looks good. I hope to finish the chassis

wiring this coming weekend to pump some sound through it for the first

time.

[April 29, 2004]

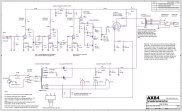

During the final stages of wiring, I realized that the output

transformer (OT) designations on the High-Octane schematic are for a

different transformer than what is in the attached

bill-of-material. The schematic itself does not make this clear

as it mentions a Hammond 125E in a note, but does not designate what

the OT on the schematic really is. Apparantly what it refers to

is the recommended OT for the P1 design (Aikens/Delft OT-5SE is

designated on the P1 schematic), but the one in the High-Octane

bill-of-material is an alternate OT, the Hammond 125E. This is

the OT that I am using. The schematic shows the input at pins

1&2 and the output on pins 3-6. The 125E has pins 1-6

markings on the output, but on the input side there are 3 pins that are

unmarked. I looked over the information at the Hammond web site

and searched the ax84.com forum postings for clues about how it should

really be connected.

Hammond

125E info

Hammond 125

series impedance chart

The outer two pins on the input side are to be used in place of OT

1&2 on the schematic. The center pin is to be left

open. I am not using an impedance selector switch since I am not

making this as a head unit. It will be connected directly to an 8

Ohm speaker; therefore, according to the impedance selection chart, I

use pins 2&6 on the output side for a 4K Ohm input. After the

fact, I realized that the P1 construction guide addresses this in

section 2.5. I should have paid closer attention to this part of

the document.

I finished the wiring over a week ago and after a final checkout, I

plugged it in and turned it on and it worked! I plugged in my

guitar and heard the first sounds out of it. There were two

problems with it: it had a very noticeable 60Hz buzz and when the

gain is turned up high enough, it squealed very loud. At lower

gain levels, the amplified sound was sharp and clear (except for the

induced buzz). I found an old chopstick laying around the house

and began poking on the wires inside to see if moving any of them had

any effect on either of the problems. I soon found a wire that

was not soldered in very well. When I corrected that, the 60Hz

buzz was reduced significantly, to more of a hum, but still very

noticeable; I could still hear it while playing.

I have spent some time over the last week trying to eliminate the

problems. I believe that I have the 60Hz hum corrected, but I

have not yet been able to eliminate the squeal at high gain.

After reading over the P1 construction guide again, I realized that the

two problems that I have are the most common with this amp

design. I pored over the forum postings on the ax84.com web site

looking for clues.

My first thought was that the fields generated by the transformers

could be inducing problems in each other or in the tubes, as they are

all in close proximity on the small chassis that I used. I

wrapped aluminum foil around the tubes as a shield to see if that would

have any effect. It did nothing, but I had to try as it was such

a simple thing to do before I got into anything more involved. I

was suspect of the filament wires thinking that they may be too close

to something in the critical path. I let the tubes warm up for a

while and then I disconnected the filament wiring from the power

transformer for a few seconds. This had no effect. I

decided that the filament wiring is good.

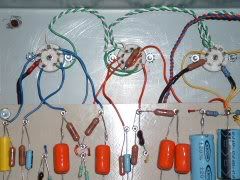

The next thing I did was to replace the input line with shielded cable,

grounding the shield at one end. This did help reduce the 60Hz

hum, but not enough. I then moved the rectifier diodes further

away from the first stage tube, V1. I have since realized that a

fundamental layout design goal is to keep the power supply section away

from the preamp section. Moving the diodes reduced the hum enough

to where it is no longer a problem. It is still present, but at

such a low level that it is not worth any more effort at this time.

I have not been able to move enough wires around to eliminate the

squeal, although I do believe that it is isolated to the preamp

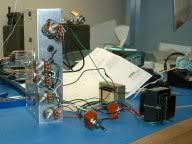

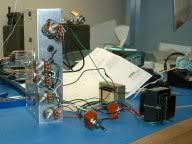

section, possibly V1. I had to know if either transformer could

be inducing the feedback (more likely the OT), so I removed them both

from the chassis to the bench, and reconnected the wiring with added

length to be able to displace them at least 10 or 12 inches from

anything else. I also tried to position all leads to the

transformers away from any other components. This did nothing to

reduce the squeal or to

further reduce the hum. Here's what it looks like today:

Short of a new layout, I am still

trying to modify what can be reasonably done to resolve this

problem. I put shielded wires on the GAIN-1 potentiometer; still

no change. Whenever I move the signal in wire at V1-2 (connected

through R10) it changes the pitch of the squeal. Moving C5 &

R6 have this affect also; they are positioned very close to R10 at the

V1A grid. These components can only be moved around so much and I

cannot get them into a position to completely eliminate the

feedback. My theory at this point is that the output of the

PREAMP STAGE 2 is too close to the input and this is the source of the

feedback. I don't know if I can expect the preamp signal to

create enough of a field to cause this feedback, but I will next try to

relocate C5 & R6 to see what I get.

I did a spot check on some of the

voltages at various points that were accessible to compare with the

SPICE circuit simulation values noted on the schematic:

V3-9 (236V)

C1 (227V)

C14

(250V)

[May 31, 2004]

I finally gave up on trying to debug

the amp. I could not move the wires and other stuff around enough

to make any difference towards eliminating the feedback squeal.

Plus I was in constant fear that having so many things loosened up to

move around I would eventually let two exposed parts touch that

shouldn't and then I'd be sinking more money into replacement parts

that I had destroyed. Also, I did get shocked a couple of times

in the process and I didn't want any more of that. Finally, the

60Hz AC hum had come back and I could not eliminate (or minimize) it

again at this point. I decided it

was time for plan B.....a totally new layout design. I scrapped

the chassis and wiring diagram that I had put so much time into.

I decided that the next one would be laid out on a turret board and

everything would be mounted to a properly sized chassis.

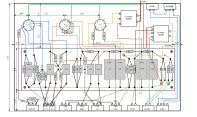

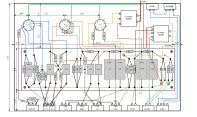

This time I decided to model my layout after one that was known to

work. I took the layout from the

silvatone

site listed below in the links and for the most part did a mirror-image

of the layout because I still want to make mine a combo unit and mount

the head in the chassis upside down. Here's my layout:

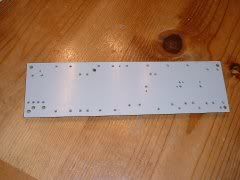

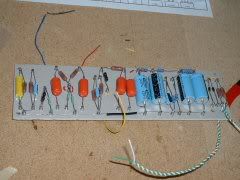

New parts had to be ordered and I cannibalized the old amp to move

all components to the new one. I bought a 12"x24"x1/8" sheet of

Garolite (G-10/FR4) from

McMaster-Carr to use for the turret board. I

also bought 50 turrets and a turret staking tool from

Hoffman Amplifiers.

This turned out to be a real nice way to mount components. I have

enough of the Garolite left over to build 5 or 6 more amps (this should

be enought for my lifetime).