Yella Terra Roller Rocker Installation Jeep 4.0L Engine

By Dino SavvaRoller rockers are infinitely stronger than stock stamped steel rocker arms and are more resistant to bending and breakage under high spring pressures at high rpm. Stock pressed steel rocker arms are prone to failure in high performance applications. A high rate of fulcrum wear, flexing, cracking, splitting and breakage are common problems that will result in power loss or possible piston failure due to detonation of the incoming air/fuel charge. The traditional metal tip on standard rockers literally drags across the valve tip as the rocker opens and closes causing high side loading on the valve. This inside force leads to irregular and rapid valve, valve guide, and valve seat wear in many engines. The roller tip on roller rockers eliminates this side loading action.

The use of needle roller bearings at the rocker fulcrum combined with a roller tip at the valve greatly reduces horsepower robbing friction in the valve train to provide a measurable power increase over standard rocker systems. The reduction in friction with roller rockers has additional benefits of reducing the operating temperature and foaming effect of engine oil to provide a cooler running engine.

Unlike stock stamped steel rockers, roller rockers maintain a constant indicated rocker arm ratio throughout the full valve lift because the center line of the roller stays constant and only its contact with the valve stem center line changes.

Stud-mounted roller rockers can rotate on their axis (the studs) and therefore require pushrod guideplates to maintain valvetrain stability plus hardened pushrods that won't wear in the guideplates. Shaft-mounted roller rockers like the Yella Terra units are inherently more stable because they cannot rotate axially, so these applications don't require pushrod guideplates.

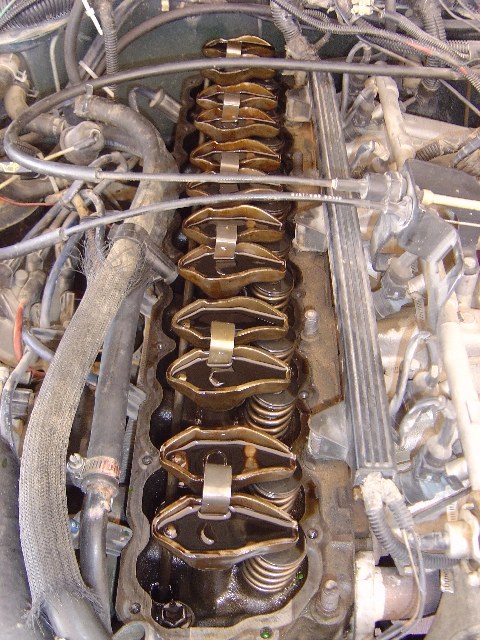

Stock Stamped Steel Rockers

Stock Stamped Steel Rockers

After running my 4.6L stroker engine for over 30,000 miles with the stock stamped steel rocker arms, the engine started to make a noticeable ticking noise especially from idle to 2500rpm. Using a stethoscope, it was obvious that the noise was coming directly from under the valve cover and it sounded homogenious. There were no localizing signs.

Time to pull off the valve cover and explore. Sure enough, the rocker arms on the no.2 and no.6 cylinders had significant sideplay and most of the others also seemed sloppy. The pushrods and valve stems looked perfect and the lifters seemed solid, but there was significant wear in the rocker arm fulcrums. This was not surprising since I'd installed heavier duty Mopar valve springs when I'd built the engine.

I reinstalled the valve cover and ordered a set of Yella Terra roller rockers in anticipation that these would cure the valvetrain noise but as you'll read further down the page, it wasn't as simple as that.

Roller Rocker Kit

Roller Rocker Kit

I bought the aluminium shaft-mounted Yella Terra 1.6 ratio roller rocker arm (YT6627) kit directly from Australia for a reasonable $364. The kit includes 5/16" capscrews, pedestal spacers, and shims to correct lifter preload.

I also elected to install new Crower chromemoly hardened pushrods (70158-12) at the same time to complete the valvetrain upgrade.

Ten days after I ordered the parts, both the Crower pushrods and the Yella Terra roller rockers arrived in the post. Like a kid at Christmas I couldn't wait to open the packages, inspect the new parts, and install them in my engine.

Installation

Installation

This was very easy except for one "small" problem. All I had to do was follow the simple instructions that came with the roller rockers. Eleven out of twelve rocker arm capscrews torqued to 25lbft at about a 3/4 turn (lifter preload 0.047") from the "zero play point", so the spacer shims that were included in the roller rocker kit weren't needed to correct lifter preload. Unfortunately the exhaust valve lifter on no.6 cylinder wouldn't preload at all on the camshaft base circle when the capscrew was torqued down and the pushrod could be moved up and down. Since the pushrod was new, that implied that the lifter was either worn or collapsed. Oh no!

The cylinder head was pulled off and, to my horror, the no.6 exhaust valve lifter had completely collapsed and the spring had popped out but there was no lifter wear. The worst news was that the no.6 intake valve lifter was severely worn and was cupped underneath, flattening the corresponding cam lobe so the Crane 260/272 degree camshaft was no longer serviceable.

Luckily I'd kept my good original stock camshaft and stock valve springs/retainers as spares so I reused them together with new lifters, new gaskets, the aforementioned Crower hardened pushrods, and the Yella Terra roller rockers to rebuild the valvetrain.

Happily the engine ran sweetly after the rebuild and the valvetrain was whisper quiet. The Yella Terra rockers do look sexy so it's a shame that you can't see them under the valve cover. Time to have a clear perspex valve cover made!