Mustang 65mm TB on Jeep 4.0L engine

By Dino Savva

I wanted to use a larger throttle body than the bored 62mm unit that I had on the 4.6L stroker engine in my 1992 Jeep Cherokee, but I didn't want to pay 365USD for the 66mm or 68mm Flometrics F&B billet aluminium units. Boring out the existing TB beyond 62mm wasn't an option either because there wasn't enough material left in order to do that safely. The only choice left was to find a larger TB from another vehicle that also had an idle air bypass and used a throttle position sensor (TPS).

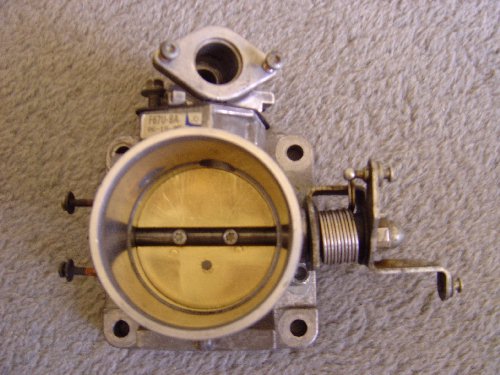

The most suitable candidate seemed to be the 86-93 Ford Mustang 65mm TB since it was the only TB that looked similar enough to the Jeep TB to be of any use. New Ford Racing 65mm TB's for the 86-93 Mustang 5.0 cost ~250USD, but I knew that I could find one much more cheaply on e-bay. Sure enough, I found one (part no. F67U-BA) from e-bay for just 79USD, stripped it down to the bare bones, and modified it for use in my Jeep.

It certainly wasn't a straight bolt-on swap by any means. The only Mustang parts that I used were the throttle body itself and the throttle plate. I sourced the throttle shaft, IAC housing, IAC module, and TPS from a spare Jeep TB that I had lying around.

Two new holes had to be drilled in the Mustang throttle plate in order to screw it to the Jeep throttle shaft, and the slit in the throttle shaft needed to be widened to accomodate the oversize plate. The plate also had to be reversed from its normal position in the TB so that it would turn counterclockwise instead of clockwise when viewed from the front. I also created a new throttle stop to prevent the throttle blade from travelling beyond WOT, and created a stop to hold one end of the throttle shaft spring so that the appropriate tension was maintained. I cut off the original throttle stop with spring and screw from the side of the TB.

I removed the angled vacuum tube from the TB and plugged the hole with J-B Weld. The Jeep MAP sensor is mounted on the firewall and the vacuum tube is connected to the intake manifold so the tube on the TB isn't necessary.

I modified the Jeep IAC housing by plugging the slits with steel epoxy, leaving only two square openings. The IAC cavities in the TB were also plugged with steel epoxy leaving just the two round holes for the air to bypass the TB bore. This enabled me to align the holes in the IAC housing with the holes in the TB, and bolt the housing in place using the Ford gasket.

The Jeep IAC module could now be used. The wiring to the IAC module needed to be extended since it is now on the opposite side to where it would normally be on the Jeep TB. The Jeep TPS is a direct fit and doesn't need to be modified.

Note from the photo how puny the Jeep TB looks in comparison to the Mustang TB. The Mustang TB is also 1" taller.

Since the Mustang TB has a wider base and the bolt holes are much further apart than on the Jeep TB (88mm v 64mm), the only challenge left was how to bolt the Mustang TB onto the Jeep intake manifold. No problem there. I just drilled new holes in the base of the Mustang TB that were 64mm apart and used the Jeep TB gasket to make sure the holes were correctly placed. I needed to trim two corners of the base of the TB to clear the throttle cable support bracket and the vacuum tube for the crankcase ventilation system.

Now the TB was ready to install. The installation itself was a breeze. It took me less than an hour to remove the old TB, bolt on the new one, and attach everything to it. I left the inlet diameter of the intake manifold and the TB spacer bore at 62mm since increasing these to 65mm would have a minimal effect on performance.

The engine started instantaneously after the TB installation and it settled at a smooth 750rpm idle. The whistle that was previously present under light throttle at 1500-2500rpm has gone and throttle response is pin sharp. Chalk another one up in the win column!