|

|

|

| Replace piston engines & inefficient turbines -- globally -- with a low-cost, low-pollution turbine engine. | Replace gasoline & diesel fuel with biodiesel, alcohol fuels from biomass, and hydrogen | Use catalytic technologies to separate carbon from the fuel prior to combustion. |

|

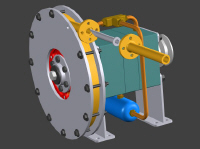

Phase I completion: 01/01/03 -- PNGinc has completed Phase I of the Phoenix Environmental Remediation Plan. We have done our part in the development of boundary layer turbines as a viable replacement for piston engines, and our KE Drive™ (Kinetic Energy) project is underway. For more information on these developments, visit the PNGinc site. |

The Phoenix Environmental Remediation Plan is the only practical approach to the serious global pollution problem. While there are many proposals from other sources, none have attacked the problem as completely -- to include factors such as implementation costs, ease of transition, and time-to-market. In contrast, we view the problem in its entirety, taking all of the major factors into account and deriving the best, most cost-effective solution for global execution. This is the only plan that outlines reclamation of greenhouse gases from the environment. Phase I: Replacement of Highly-Polluting EnginesJust in case nobody has made it clear yet, I will state it here:

It is absolutely necessary to immediately replace all piston-type engines with an alternative. Gas turbines produce only 50% of the toxic emissions of piston engines, even when using the same fuels. By implementing next-generation designs such as the Phoenix Kinetic Energy Drive & boundary layer Turbines, efficiencies increase, pollution decreases further, and low manufacturing costs allow widespread economical use. Turbines are the only high-horsepower alternative engines presently available. Pulling power, which is the key to maintaining a trucking-based economy, must weigh heavily in the solution. Truckers, fleet operators, environmentalists, politicians, the general public -- even truck manufacturers -- will be satisfied with the results of our piston engine replacement plan. Phase II: Replacement of Fossil FuelsThe problem with burning fossil fuels (coal, gasoline, diesel, etc.) is that the net gain of greenhouse gases upsets the naturally-balanced ecosystem. The continuously climbing rate of CO2 production has exceeded the global plant-life conversion process. The results have suddenly become catastrophic:

We have reached the point of a total ecosystem meltdown in which the oxygen production centers of the planet (forests, jungles, etc.) are collapsing. Within 20 years, all animal life will be competing for dwindling oxygen reserves. In Phase II of our program, we eliminate the cause of CO2 net gains -- fossil fuels. In place of these fuels we use a natural-state-liquid fuel in order to continue using the fuel distribution system now in place. The only fuel now available that can satisfy energy demands without disrupting the fuel distribution infrastructure is alcohol. Methanol is cheaper to produce than gasoline, and is cleaner burning. Ultimately ethanol is the fuel of choice to replace gasoline & diesel. Since it is a bio-fuel, made from plant material, ethanol fuel combustion results in no net gain in greenhouse gases. Global use of alcohol will reduce pollution when used as a motor fuel, and will eliminate toxic emissions in fossil fuel production. Phase III: Air Quality Improvement ProcessAccording to environmental experts, even if all combustion were to cease immediately, 50% of air pollutants will remain in the atmosphere for another 100 years. In Phase III of our plan, we have devised a practical and economic means of rolling back greenhouse gas content. The best low-cost method of reclaiming CO2 from the environment is to use plant life. Plants convert CO2 into fiber; the fiber is turned into ethanol fuel. Once the fuel is pumped into the vehicle, a catalytic separator will remove all carbon from the alcohol chain, liberating pure hydrogen and oxygen for 100% pollution-free combustion. This cycle will dynamically draw carbon from the ecosphere, never to be re-introduced. So where will we get this futuristic molecular scrubber? Phoenix Navigation & Guidance Inc. has the designs & development is underway! Ken Rieli, Chairman |

Last modified October 16, 2003 12:42 PM