|

Tuesday, 31 July 2018

Nano Tungsten Oxide Photocatalyst Paper-based Bamboo Curtain

Mood:

Nano Tungsten Oxide Photocatalyst Paper-based Bamboo Curtain

Mood:

a-ok

Topic: Nano Tungsten Oxide a-ok

Topic: Nano Tungsten Oxide

Due to the changes in life and work patterns, modern people spend more and more time in the indoor environment, and almost 90 percent of the time is spent indoors. As a result, the poor indoor air quality leads to a large number of “Sick Buildings”, and the number of people suffering from “Architectural Disease Syndrome” is increasing. The extensive use of new building materials, especially chemical synthetic building materials, has led to the continuous increase of harmful substances in the indoor air, which has led to a serious decline in indoor air quality. The photocatalyst is the general name of photocatalytic photo semiconductor material, which is represented by Nano titanium dioxide. It is one of the safest materials to control indoor environmental pollution in the world. Photocatalyst can produce photocatalytic reactions similar to photosynthesis and free hydroxyl and reactive oxygen species with strong oxidation capacity under light irradiation, which can oxidize and decompose various organic compounds and some inorganic substances, and destroy the cell membrane of bacteria and solidify the protein of virus, kill bacteria and decompose organic pollutants, as well as decompose organic pollutants into pollution-free water, carbon dioxide and other harmless substances. Therefore, it has a strong function of sterilization, deodorization, anti-mildew, anti-fouling, self-cleaning and purifying air.

Recently, scholars at home and abroad have achieved certain results in photocatalyst treatment of textile and bamboo materials. In fact, photocatalyst has different prospects in the decoration and furniture field with the general improvement of people's living health and environmental protection requirements, and the materials with the function of photocatalyst purification are more and more popular. Nano tungsten trioxide is an important type N semiconductor. Due to its good optical and electrical properties, it is widely used in lithium-ion batteries, electrochromic devices, gas sensors and photocatalysis, and its popularity is no less than titanium dioxide. For example, some enterprises have used Nano tungsten oxide to prepare a photocatalyst paper-based bamboo curtain in product innovation. The purification effect of the Nano tungsten oxide photocatalyst paper-based bamboo curtain is 10-20 times that of the existing titanium dioxide photocatalyst, according to the authoritative measurement, and it can produce strong light contact effect under the condition of ordinary visible light. The degradation of formaldehyde can reach more than 70% through the 24-hour room temperature test of white light, black light, and common paper-based bamboo curtain. In a word, its light conversion efficiency is higher, so it can degrade formaldehyde, harmful particles, peculiar smell, and pathogenic bacteria more effectively. Stanford Advanced Materials supplies high-quality tungsten products to meet our customers' R&D and production needs. Please visit http://www.samaterials.com for more information.

What are the uses of Tungsten Alloys Disc?

Mood:

What are the uses of Tungsten Alloys Disc?

Mood:

a-ok

Topic: Tungsten Alloys Disc a-ok

Topic: Tungsten Alloys Disc

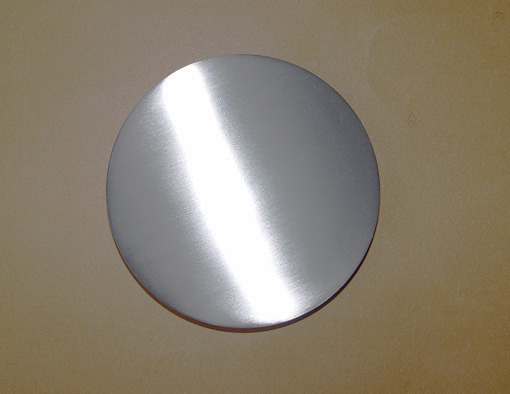

Tungsten alloys are alloys based on tungsten with other elements added, while tungsten alloy disc is made of tungsten-molybdenum alloy or tungsten thorium alloy or rare earth tungsten alloy or tungsten-rhenium alloy. Tungsten alloy disc is easy to process and has better performance than that of molybdenum disc, so it is commonly used as the substrate of electric semiconductor devices and electric vacuum devices. According to the material, tungsten alloy disc can be divided into the hard alloy, high specific gravity alloy, metal perspiration material, contact material, electron and electric light source material, etc. It has many excellent properties, such as high density, high hardness, high strength, high melting point, heat conduction, electric conduction and electron emission, which is widely used in aerospace, aviation, military, oil drilling, electrical instrumentation, medicine and other industries. The application of tungsten alloy disc in the mechanical industry is listed below.  It can be used to process ionic injection parts, make electric light sources and electric vacuum parts, and produce cover plates in a sapphire crystal growth furnace, and it can also be used in the hair tropics, connectors in the vacuum furnace, as well as plasma coating sputtering target materials and tungsten boat products;. It is suitable for making cast iron roll and high nickel chrome roll dressing and forming tool; It is applicable to manufacture discharge plate, punch die, punch die, punch die, electronic progressive die and other stamping dies; It can be used as tungsten steel liner; It is used to make wear-resistant parts; It can be used for processing high-density fiberboard, density board tungsten steel liner; It has a high cost performance. Besides that, hard alloy disc is used for cutting hard materials such as copper parts and stainless steel parts. The monolithic cemented carbide disc cutter is suitable for cutting or grooving of ordinary steel, alloy steel, quenched steel, copper, aluminum, stainless steel, titanium alloy and other metal materials and electronic printed circuit board, cement stone tile, wall tile, paper, adhesive paper, rubber, leather and other non-metallic materials. Stanford Advanced Materials supplies high-quality tungsten products to meet our customers' R&D and production needs. Please visit http://www.samaterials.com for more information.

Wednesday, 25 July 2018

What is the Single Crystal Blade?

Mood:

What is the Single Crystal Blade?

Mood:

a-ok

Topic: Single Crystal Blade a-ok

Topic: Single Crystal Blade

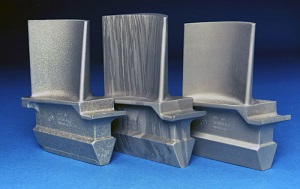

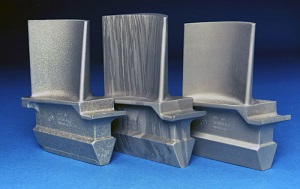

Single crystal blade is a casting blade with only one directional crystalline grain, which eliminates the lateral grain boundary sensitive to cavitation and cracks and makes all grain boundaries parallel to the stress axis, thus improving the performance of the alloy. Single crystal turbine blades have been crucial to the development of jet engines over the past 60 years and have been an important technology for the aerospace industry.  The main material used in aero-engines is nickel-based high-temperature alloy. Normally, nickel can bear the high temperature of 1000℃ or so, but it is easy to oxidation and deformation at high temperature. Therefore, other refractory metal elements need to be added to keep the nickel base high-temperature alloy blades strong and resistant to oxidation at extreme temperatures, which means that the nickel alloy blade material closest to the engine combustion chamber must be able to operate at temperatures well above its melting point and must be cooled to 80 to 90 percent of its melting temperature. As a result, the alloy material used in the engine blade is the key factor to determine the performance and life of an aero engine. The development of single crystal blades dates back to the 1950s when engineers in the United States went from concept to manufacturing for about 10 years. In 1966, American engineers created directional solidified columnar grain turbine blades, which are the first step toward single-crystal blades, and the nickel-based alloy contains carbon, boron, and zirconium. By the 1970s, American engineers had continued to build on the first generation of improvements to make a new alloy, which is the single-crystal castings called SX alloys that are still in service today. The SX alloy replaced carbon, boron, and zirconium with the new monocrystalline formula, which roughly includes nickel (59%), cobalt (10%), tantalum (9%), aluminum (6%), tungsten (6%) and other elements (10%). Among other elements, the most important material is rhenium (3%), which allows the final alloy to withstand higher temperatures before weakening and melting. The single crystal is a superalloy grown from a single crystal in a vacuum casting furnace. It can improve the efficiency and service life of a turbine while giving it unparalleled resistance to high-temperature creep and fatigue. In a jet engine, the relative life of a single crystal turbine blade has been shown to be up to nine times higher in terms of creep strength and heat resistance fatigue than that of an equiaxial crystal blade, and the corrosion resistance of the relative life more than three times.

Stanford Advanced Materials supplies high-quality metal products to meet our customers' R&D and production needs. Please visit http://www.samaterials.com for more information.

Tungsten-titanium Heterogeneous Structure & Intelligent Window Coating

Mood:

Tungsten-titanium Heterogeneous Structure & Intelligent Window Coating

Mood:

a-ok

Topic: Intelligent Window a-ok

Topic: Intelligent Window

Tungsten trioxide is both an N-type semiconductor material and a "D0" oxide, and the dual identity gives tungsten oxide catalytic, optical and electrical properties, which makes it the basis of industrial manufacturing such as smart windows, electronic packaging, secondary lithium batteries and gas sensors. From the mid-1970s to the early 1980s, most studies on the electrochromic properties of tungsten trioxide have focused on electronic display devices. However, due to the limitation of its low color conversion rate, the research gradually turned to the emerging fields such as smart windows. Although the latter requirement for the response time of color change is not as strict as that of the display device, it is still a widely concerned research focus until now.

However, membrane dissolution and ion residue will occur with the injection and extraction of ions during the use of WO3 thin films, and the electrochromic property will decline significantly, which limits the widespread use of electrochromic devices. So scientists are looking for new materials with extraordinary properties, but no perfect materials have entered the commercial market from the laboratory so far. Recently, scientists in the United States have linked titanium and tungsten, two materials with different crystal structures, to create a new material with a different structure, which was considered impossible in the past. But with advances in technology, scientists have been able to ensure that crystal bonds can last in everyday life and then be used in industry. A mixture of several metals is usually called an alloy, but other materials can also be alloying. In semiconductors, for example, nitride and oxide alloys have been used successfully for a long time to change the functional properties of materials, and the changes usually occur slowly and the properties of the substrate can still be easily identified. In contrast, heterogeneous structural alloys are formed when compounds with completely different crystalline structures are mixed together. In these types of alloys, the mix ratio based on the composition changes in the structure. Sometimes unexpected properties are formed, which is quite different from the properties of the underlying material. Scientists must understand both the properties of tungsten and titanium in the process of finding the materials needed, such as the electronic properties, structures, and long-term stability. In the laboratory, mixed oxides made of tungsten and titanium oxides are the primary focus of heterogeneous structural alloys that can be used in sensor technology, window coating or semiconductor technology.

Stanford Advanced Materials supplies high-quality tungsten products to meet our customers' R&D and production needs. Please visit http://www.samaterials.com for more information.

Monday, 16 July 2018

How to protect Metal Resources?

Mood:

How to protect Metal Resources?

Mood:

a-ok

Topic: Metal Resources a-ok

Topic: Metal Resources

Metallic materials are an important material basis for the development of human society, and most metallic elements exist in minerals in the form of compounds in nature. As a result, millions of tons of metal are extracted from metal minerals each year for industrial and agricultural purposes, the largest of which is iron.

The process of obtaining metal elements from metal minerals is called metal smelting. Different metal smelting methods are different, the more active the metal, the more difficult the smelting process. According to the metal activity sequence table, we can know that it is most difficult to smelt active metal potassium, calcium, sodium, magnesium, and aluminum. For these metals, electrolysis is used in the production in practice, and only when a metal compound is fused by electrolysis can a metal be obtained. The less active metals such as iron, molybdenum, tungsten, and copper are usually obtained by CO reductants and mineral reactions; mercury and silver metals are usually obtained by heating and decomposing their minerals; the most stable platinum and gold are found in nature in the form of a single substance, which can be obtained directly from the ore. This may explain why the history of human use of metals began in the Bronze Age, followed by the Iron Age, followed by aluminum products. However, the reserves of metal minerals are limited and cannot be recycled, so how to protect the metal resources has become an urgent problem. After analysis, we can solve the problem from the following aspects. First of all, control the centralized development of resources in the development process to avoid the waste of symbiotic metals due to limited development conditions. Secondly, it is important to do a good job in the use of metal corrosion prevention. It is reported that the world's annual corrosion of metal equipment and materials is equivalent to 20-40% of the annual output. Common anticorrosion methods include coating metal with plastic, painting, painting oil, enamel, plating more corrosion-resistant metals (such as copper, chrome, etc.), adding metal chromium and nickel to make stainless steel, etc. Finally, we should actively develop new materials to replace the original metal materials. Please visit http://www.samaterials.com for more information.

How to protect Metal Resources?

Mood:

How to protect Metal Resources?

Mood:

a-ok a-ok

Metallic materials are an important material basis for the development of human society, and most metallic elements exist in minerals in the form of compounds in nature. As a result, millions of tons of metal are extracted from metal minerals each year for industrial and agricultural purposes, the largest of which is iron.

The process of obtaining metal elements from metal minerals is called metal smelting. Different metal smelting methods are different, the more active the metal, the more difficult the smelting process. According to the metal activity sequence table, we can know that it is most difficult to smelt active metal potassium, calcium, sodium, magnesium, and aluminum. For these metals, electrolysis is used in the production in practice, and only when a metal compound is fused by electrolysis can a metal be obtained. The less active metals such as iron, molybdenum, tungsten, and copper are usually obtained by CO reductants and mineral reactions; mercury and silver metals are usually obtained by heating and decomposing their minerals; the most stable platinum and gold are found in nature in the form of a single substance, which can be obtained directly from the ore. This may explain why the history of human use of metals began in the Bronze Age, followed by the Iron Age, followed by aluminum products. However, the reserves of metal minerals are limited and cannot be recycled, so how to protect the metal resources has become an urgent problem. After analysis, we can solve the problem from the following aspects. First of all, control the centralized development of resources in the development process to avoid the waste of symbiotic metals due to limited development conditions. Secondly, it is important to do a good job in the use of metal corrosion prevention. It is reported that the world's annual corrosion of metal equipment and materials is equivalent to 20-40% of the annual output. Common anticorrosion methods include coating metal with plastic, painting, painting oil, enamel, plating more corrosion-resistant metals (such as copper, chrome, etc.), adding metal chromium and nickel to make stainless steel, etc. Finally, we should actively develop new materials to replace the original metal materials. Please visit http://www.samaterials.com for more information.

Why is the Back Cover of Zirconium Oxide Ceramic difficult to popularize at present?

Mood:

Why is the Back Cover of Zirconium Oxide Ceramic difficult to popularize at present?

Mood:

a-ok

Topic: Back Cover of Phones a-ok

Topic: Back Cover of Phones

With the development of smartphones, more and more demands have been placed on mobile phone materials. The back cover of zirconium oxide ceramics is popular because of its excellent performance, but it is difficult to popularize because of its high cost and low production capacity. The following are some reasons why zirconia cell phone covers are difficult to be popularized at this stage. Zirconia ceramics have the highest cost in terms of cost, followed by metal, and glass is the cheapest. A piece of zirconium oxide back cover is expected to cost about $30, and a piece of 2.5-d glass costs about $4. In terms of production capacity, zirconia ceramics are currently subject to the production capacity restrictions of powders, resulting in the limited capacity of the back cover, which cannot meet the demand of hundreds of millions of mobile phones.

The back cover of zirconia ceramics adopts precision ceramic processing technology, and its material production and processing technology are complicated, which usually consists of dozens of processes control and material control, mainly including upstream powder materials, mid-stream molding/sintering, and post-processing, and there are countless options at each stage. After sintering, the finishing grinding treatment can only improve the surface performance. In order to ensure the size and precision of finished products, the shrinkage and consistency of materials, raw porcelain and sintering should be considered, and repeated experiments and improvements should be made, the technical know-how presented in which constitutes a huge threshold for the manufacture of zirconia ceramic cover. Material process Doped and modified with rare earth elements on the basis of advanced nano-zirconium oxide powders, chemical adhesives and other materials are added to form a viscous solution with the organic solvent as a carrier. Sintering process The control of the temperature curve and the atmosphere is the key to product quality. In the post-sintering process, the finished porcelain is grinded and modified according to the different products to ensure the consistency of its performance and physical structure. Please visit http://www.samaterials.com for more information.

Tuesday, 10 July 2018

What are the Excellent Properties of Tantalum Capacitors?

Mood:

What are the Excellent Properties of Tantalum Capacitors?

Mood:

blue

Now Playing: Tantalum Capacitors

Topic: Tantalum Capacitors blue

Now Playing: Tantalum Capacitors

Topic: Tantalum Capacitors

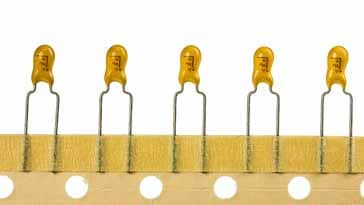

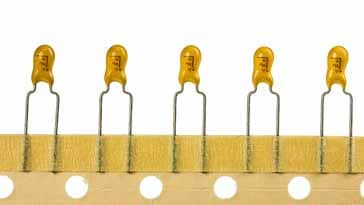

Tantalum capacitors have many excellent properties and are widely used in military communications, aerospace, industrial control, film and television equipment, communication instruments and other industries.  Tantalum capacitors are a kind of electrolytic capacitors, and they use metal tantalum as a medium instead of electrolyte as common electrolytic capacitors. Tantalum capacitors do not need to be wrapped in aluminum-coated capacitors like ordinary electrolytic capacitors, and tantalum capacitors themselves have little inductance, which limits their capacity. The working medium of tantalum capacitor is a thin layer of tantalum peroxide film formed on the surface of tantalum metal, which is integrated with one end electrode of the capacitor and cannot exist alone. Therefore, tantalum capacitors have very high working electric field intensity in unit volume, and their electric capacity is especially large, so it is especially suitable for miniaturization. Tantalum capacitors have excellent performance. They are small capacitors with large capacity, which has few competitors in power filtering, ac bypass, and other applications. Tantalum electrolytic capacitors have the properties of storing electricity, charging and discharging, and are mainly used in filtering, energy storage and conversion, marked bypass, coupling and decoupling, and as the time constant components. Attention should be paid to its performance characteristics in the application, which include measures such as the working environment of the product and its heating temperature, as well as the use of reduced volume. Proper use will help to give full play to its functions; otherwise, it will affect the working life of the product. The tantalum capacitor has the function of repairing or isolating the defects in the oxide film, which enables the oxide film medium to be reinforced at any time and restored its due insulation capacity without continuous cumulative damage. This unique self-healing performance ensures its long life and reliability advantages. Please visit http://www.samaterials.com for more information.

Tuesday, 10 July 2018

How far are we from the Space War?

Mood:

How far are we from the Space War?

Mood:

blue

Topic: Space War blue

Topic: Space War

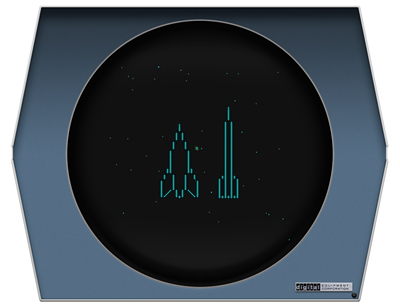

Warnings of an imminent space war have been ringing up in recent years. David Goldfein, the U.S. Air Force Chief, said that the space war between the superpowers could begin in a few years' time in February 2018, while space weapons are the No.1 weapon in Russia's hypothetical Third World War. The New Global Threat Assessment Report, released by the office of the director of National Intelligence, also warns of the growing possibility of space wars.

Much of the pessimism about the space war has been driven by the sudden spurt of the world's great powers in space and the implicit militarisation of the latest space technology. The use of space for peaceful purposes is widely recognized around the world. In recent years, Russia has submitted draft resolution “No First Deployment of Weapons in Space” to the United Nations general assembly every year, and the hope is that a legally binding agreement will set a credible obstacle to an arms race in space. By 2017, 130 countries had voted for the draft resolution. Of course, the Outer Space Treaty signed in 1967 is still in force. The treaty obligates all parties not to use weapons of mass destruction in space, and more than 100 countries have signed and complied with the document. Over the past 50 years since its implementation, the treaty has largely regulated the space activities of all countries in the world. Some space missions that violate the treaty still exist, but at least they are less blatant. From the purely military perspective of defeating the enemy, deploying weapons in space is tempting to any country because it offers the infinite possibility of destroying the enemy, as Russia's Internet.com commentary says, such as destroying the enemy's "eyes and ears" (satellites used for communications and reconnaissance) at the beginning of a war, as well as the currently disclosed space laser guns, aircraft robotic arms, suicide satellites, etc., all of which are capable of anti-satellite missions. The deployment of weapons systems in space would also make it easier for ideas such as the U.S. Military's "Prompt Global Strike" to materialize. As we've seen in science fiction movies, dropping non-nuclear kinetic weapons, such as refractory tungsten rods, out of orbit would leave the air defense system helpless, and it would do as much damage as nuclear weapons. Please visit http://www.samaterials.com for more information.

Newer | Latest | Older

|