His designs use inexpensive materials, and are extremely underpriced, but I

am not complaining. The AF4 plans I bought from him came quickly and seem

very complete. The drawings were large and easy to understand. There

were instructions and specifications, and there were also several pages of

invaluable discussion of materials and choices. I have bothered Jim

several times with questions before I chose his design, and he answered me

patiently and quickly.

My original question to Jim was whether or not the AF4 would handle the

rather rough chop in our coastal sounds. I mentioned to him that I had

many rather wet, miserable, and hair-raising experiences trying to get to the

barrier islands in a 17ft flatbottomed aluminum johnboat. His response was that

the AF4 was perhaps not the design for this purpose. He suggested that I

look at Kilburn Adams's Skiff

America. I took a look, and he was right,

for rough water, the Skiff America was obviously the better design. Plus

the boat was gorgeous. It was also designed to use smaller outboards, and had a

cabin much like the AF4. But the building method was obviously more

involved than the AF4 and then I read this statement, "The completed

boat with all necessary materials: motor, trailer, bimini, steering gear,

paints, epoxies, cushions, marine hardware, EVERYTHING, for the entire package

will cost $8,500 (at the time of building)." I understand that this is not unreasonable,

but it shocked me. I've got a trailer that will fit an 18ft flatbottom.

I've got an outboard barely sufficient to power the AF4, perhaps a little small for

Skiff America (an 8hp Johnson and a 3hp Sears for a kicker). I was thinking

about putting $500-600 into the boat itself, tops. Perhaps I could have

built a bare Skiff America for that, but I began to think not. I also

looked at the GP-16 by Jim Betts. It also would have met many of my

requirements, and been much more roomy for two campers. But again, it had

a very wide beam and would have required getting another trailer and

motor. Even as a relatively inexpensive boat to build, it still could not

compete with the AF4. Remote steering would have been required here, too. I looked

at the Harmonica too, but took Jim's words to heart. This was not the boat

for anything but small placid lakes. It was fodder for many pleasant

daydreams though.

So I chose the AF4. I liked its looks best of all the plans I

considered. I figure I might slowly sneak across the Sapello Sound on a

calm day in the AF4, to get from one river mouth to another, but mostly I will stay out of the wide water and keep to

the inland rivers and creeks. Besides, Jim says he might eventually do a

boat with AF4 capabilities but with a rough water hull. I'll be ready.

I think the AF4, by and large, fits this project very well. So there is

very little I need to do other than build it as designed.

One would think that Southeast Georgia would be

a likely place to find marine plywood, bronze screws & nails, fiberglass,

epoxy resin, etc. But I have not found that to be the case. My

search for plywood locally has led me to this conclusion. People here

don't build boats much, and when they do they slap them together with particle

board, poly-glass, ply sheathing, liquid nails, sheetrock screws, and the

like. They use them for work and scrap them after a season. Each

time I built a boat, I took a stab at finding marine ply. I never found

marine ply at sizes under 3/4". On my first boat I decided to use BC

pine from the lumberyard a mile from my home. It looked good, with few

knots or voids. I used it. I glassed the bottom and sides outside,

and just the bottom inside with a really lightweight cloth 3 oz and epoxy.

A month later the inside sides that I didn't cover with cloth began to check a

lot. The resulting cracks were so thin that it was difficult to get paint

into them. As soon as the paint would dry, the cracks would appear

again. I vowed to use better plywood on my second boat. On my second

boat, I used AC fir exterior. I shopped around to find a lumberyard that

carried it in a nearby town. When I got there I was astounded at the

knotty junk they loaded into my truck. I got it home and looked at it, and

decided that it was still lighter and once I filled the knots, would be better

than BC pine. I basically rebuilt the C face with Elmer's wood

filler. It wasn't until after I had built this boat that I read that the

only wood worse for checking than BC pine was AC fir. I didn't keep either

long enough to see how they held up. I built my third boat, a

Bolger Skimmer, of 1/4" Luaun. I did not glass anything but the

seams, I coated once inside and out with epoxy. I painted with exterior latex

semigloss. It has held up great after 1 1/2 seasons of heavy use, but I

don't like "skimming" at speed on a crunchable piece of luaun.

It makes me feel week in the spine.

So what will I build my AF4 out of. BC pine of course. I will

glass every last smidgin' of it inside and out with light cloth and epoxy to

avoid the checking. I will tape the outside chines, and I will use a

heavier (though not really heavy) 6 oz glass on the bottom. Therefore my

boat will be MUCH heavier and probably cost more than if I could find a more

expensive marine ply that would not check and just painted it. Because I am

basically sealing my boat inside and out with epoxy-glass, I will use epoxy as

glue for the rails, chines, butt blocks. But I will use either weldwood

plastic resin glue or PL Premium on the bulkheads and framing sticks. I

have some of both and intend to experiment a little. I recently read a

statement by Chuck Leinweiber who built the Caprice (another Michalak

boat). He said that epoxy on his boat released its bond when the wood it

was stuck to got wet. He said that apparently this was common knowledge

and was one of the reason's epoxy manufacturers recommended encapsulation.

Until I heard this, I had considered using epoxy for glue and chine taping, but

not encapsulating the wood at all, as this would be significantly cheaper.

But now if I took that route, I don't think I would use epoxy at all. But

I am going the other way. Here's why:

I'll be curious to see how Max's AF4 holds up by comparison. Maybe I'm

just another of those epoxy slatherin' idjuts who have more money than sense

(and I ain't got much money). If mine lasts a decade, I'll have got my

money's worth, even with all that epoxy.

So far I know of two other AF4 builders online, although there have

definitely been many more than that built. They are:

September 1, 2001

Drove all over Savannah, GA looking for boatbuilding plywood. Ended

up with BC pine exterior from Home Depot. It was nice looking wood

though, few to none knotholes on the C side. I waited on the 3/8 inch

sheets though. HD didn't have any but the Lowes next door did. But

as I was loading the 1/4 sheets it started to sprinkle. We've been getting

sudden severe thunderstorms daily, and I decided to hurry home instead.

Right now Brunswick HD has better looking 3/8 anyway. So I hope to pick

up the rest next weekend.

I have decided to stay with 3/8 inch ply, as in the original plans, rather

than switch to 1/2 (as later recommended by Jim), because I am going to glass

the bottom with at least a 6 oz glass.

September 8, 2001

Spent the rainy weekend indoors working on this website, surfing up ideas

for camping foodstuffs, and thinking about other project related

problems. No serious breakthroughs, but a few new dilemmas. For

example, how much fresh water will we need for a two week trip? and will we be

able to carry that much with us? and if not where will we be able to acquire

more en route? This might be easier to answer if I had decided on a

route already. This should be a primary consideration in choosing a

route. We simply must have a few places where we can stop and buy water

and fuel.

September 15, 2001

Purchased the final pieces of BC pine plywood. At the last minute I decided

to buy 1/2 inch. I found myself staring at HD staring at the 3/8 stack

and the 1/2 inch stack side by side. The 3/8 looked a lot better, less

knots, thicker exterior plies etc. The 1/2 inch center plies were

complete junk of course, but the sanded side ply was extremely thin. On

one hand the 3/8 looked better and I knew I would be using a layer of glass

cloth on bottom. On the other hand, Jim Michalak says use 1/2 and that

it should be twice as stiff. I flexed the 3/8 then tried to flex the

1/2. Yep. Bought the 1/2 inch.

My workshop has a dirt floor. I am looking at building 18 inch high

sawhorses, or concrete blocks, or something.

October 8, 2001

Okay, this three day weekend I ran the Altamaha, from Champney River ramp

to the Altamaha Park in Everette City. More about that in the Camping

section. I also cleaned up my shed, added a new section of tin,

increasing the overhang on the "boat assembly area," and set up the

sawhorses and worktables like I wanted them. As usual, each step forward

was had several hitchhiker tasks. For example, adding the tin, required

setting up the ladder, which required clearing inconveniently placed

brush. Then when I got up top to fit and nail the tin, I discovered that

my shed roof was covered with leaves, acorns, and pine needles, so I wound up

carefully sweeping it. And I must say, the incline was plenty steep

enough. One would think the leaves would just slide off. The

lovely one came out to help me move the fiberglass boat, and wound up spending

a few hours raking my dirt floor, picking up scraps, tending the burn pile,

and bringing me cold water and bug spray. She also helped me with the

roof before going in to make a hot pot of chili for supper.

Anyway, late Monday afternoon, I finally began my first actual

cutting/construction task. I built temporary forms #6 and #13.

These are rather simple frames made from 1X4s. But it was good to

begin. Though I felt a pang when I realized that since these pieces will

not ultimately be a part of the finished boat, I haven't really made my first

"cut" yet. I hope to squeeze some time in after I get off

work. There are still some hours of daylight, though the days are

getting shorter.

October 13, 2001

I completed bulkhead 10 and bulkhead 2. I had some trouble with my

Weldwood plastic resin glue. It simply did not turn into glue when I

added water. I followed the instructions, read and reread them.

Mixed several batches. I noticed several things. First 2 parts water to

5 parts powder, did not even thoroughly wet out the glue. Second, adding

more water did little to help. When I finally got a "cream"

like consistency, I applied it to some test pieces. It responded like

wet sand. It looked liquid enough, but as soon as pressure was applied

or as it dried, nothing was left but a damp grainy powder with no adhesive

properties to speak of. Both containers were purchased from a local

hardware store, and they both acted the same way. I suspect they could

have been on the shelf since 1978, perhaps there is a shelf-life for this

product. I must check. I used PL Premium instead. I will use

Epoxy on the butts, the wales, and chines.

As I lay in bed, visions of bulkheads dancing in my head, I suddenly saw a

vision. In my mind I could see the plan drawing of bulkhead 10, its

topsides sloping downward from the center. But wait a minute, the

bulkhead I fashioned seemed to be flat across the top. Could I have made

such an error? I dug the plans out of their manilla envelope, and

looked. Yes there was a 3" rise from the top of the sides to the

top inside of the hatchway. Surely I cut them that way.

October 14, 2001

My first major goof. Somehow I totally goofed up the top of bulkhead

10. After some deliberation, I simply screwed and glued on a wedge

shaped 2X4 faced with 1/2 ply. I countersunk the screws deeply through

the top and used plenty of glue. The result was a rather Frankenstein looking

job. I filled the holes and sanded, I am facing it front and back with

fiberglass cloth, so I think it will be strong enough. It seems pretty

sturdy right now.

October 17, 2001

I just learned that Jim has completed the plans for the AF4 Grande.

It is a scaled up version of the AF4, though still flatbottomed. It is

21 feet long instead of 18, and the cockpit is 7 feet in length instead of

6. Now many times I have looked at the AF4, especially after I completed

my model and tried to lay down the to-scale paperdoll Rav in the cockpit, and

thought wistfully, if only it were just a little bigger. On the other

hand, I still have an 8 HP Johnson, and a trailer just barely (hopefully) big

enough for an 18 footer. And, after the big Rav and DP river trip, I

will most likely be camping solo for one or two nights tops. And even 18

foot of boat is bulky for some of the channels I'll be fishing and navigating.

So right now, I've sent Jim a check for the plans, and reserving ultimate

decision until I see them. I confess that I would like to be the first

to build and document a new Michalak design--even if it is a scale-up.

But it would mean almost a total start over on the plywood, and would set me

back a couple hundred. And I am a cheapskate.

October 19, 2001

I've decided to continue building while I await the AF4 Grande plans.

If I start over, the framing sticks, glue, fasteners, etc. I use this weekend

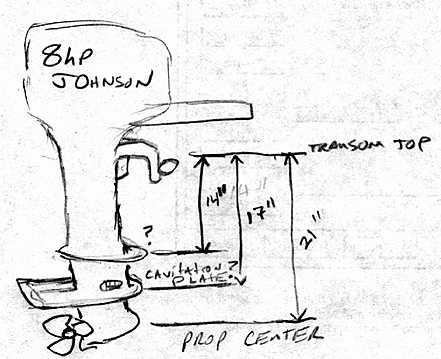

won't make much difference in cost loss anyway. I completed the transom

today. I added the motor mounting board because it was shown on the

construction drawing. Upon rereading the plans, I see it is one of the

last pieces added. This raises a question that I have never successfully

had answered. Just what is the proper transom depth for my motor. I have

been using it on the 15" transom on my john boat for years, but I am not

sure if the motor is considered long shaft, short shaft, standard or

what. The question is further complicated because this motor has two

cavitation type plates. I'll ask Max about it, as he has obviously seen

a few outboard motors.

October 20, 2001

Max says my motor is a short shaft model. This is a relief. I

plan to leave the transom as spec'd. I may monkey around with it after

the boat is tested. He also explained what the inlet at the top of the

cavitation plate is for, and gave me some good estimates of what I can expect

with an 8 hp motor, Rav & DP and gear. Thanks Max!

October 21, 2001

Today I did cleanup on the bulkheads. I filled holes, replaced

sheetrock screws with galvanized deck screws, bronze nails, etc. I cut

bulkhead 16. For some reason I kept screwing up the bevels and length of

the framing sticks. I wasted an entire 6ft 1X4. I cut the stem

from a pressure treated 2X4. Although I plan on sealing the frames with

epoxy and light cloth before assembly (just so much easier horizontal) and

possibly cutting my vent, I am technically done with the construction of all

frames, stem to transom. I must order epoxy and glass from Raka

soon. The quart or so I have left will not go far. The next big

move will be joining the 2 1/2 sheets of ply together and marking and cutting

the sides.

October 23, 2001

Today I bought Fiberglass and Epoxy from Raka

Marine. I bought:

- 6 yds of 6oz (T) 50" cloth @ $5/yd =$30.00

- 21yds of 1.5oz 40" cloth @ $2.75/yd = $57.75

- 1 roll of 6oz 3" fiberglass tape = $24.75

- 3 gals epoxy (2gals resin + 1gal slow hard) = $118.00

- 4 mixing pots 16oz = $2.00

- 5lbs pine wood flour = $10.00

Total = $254.91

I can't help it. It doesn't matter that I am building a boat, that

Raka epoxy is cheap, that I am getting my money's worth. When that kind

of money leaves my wallet I gotta cry a little. Whaaaaaaaaaa . . aaahhh.

I'll be okay again by the time the order arrives. I think.

October 26, 2001

The Raka order is here! After a seeming hour of distracting errands,

I get out to the boatshed with my new supplies. Maybe I'll coat a few

frames, cloth bulkhead 2, or the transom, while I still have them

horizontal. But I have forgotten something essential. Cheapo

paintbrushes. Bah, It will have to wait until morning. Plus, dp

calls on Friday nights. Ah, It's time right now. gotta go.

October 28, 2001

I have decided to continue to build the AF4 and save the AF4 Grande for

next time. One day I will buy a 15hp Honda 4 stroke and a new galvanized

trailer, but not this year. And what better practice for building an AF4

Grande than building the AF4! I can make all my mistakes, work out all

my modifications and customizations on this boat, and then implement them on

the next one. Plus I am such a slow builder, I'd be kidding myself to

think I would be first to complete the AF4 Grande. A side note though, I

was just reading a book called Tidecraft by Rusty Fleetwood. In it are a

lot of photos and sketches of boats used in the Carolinas and Georgia coastal

waters. There were two boats used in Fernandina, FL as shrimping

trawlers, the Rene Goddard and the Sebastiana G, which had raised decks and

lines amazingly similar to the AF4. Their LOA was not given but the Rene

Goddard looks to be easily twice the length of the AF4. It was designed and

built in St Marys, GA by Alex Mcdonnell, circa 1915.

October 29, 30, 31, 2001

Ah the fall is here, and the harvest has begun. But now I have once

again snagged myself. I have ordered Raka epoxy and Very Slow Hardener

as I always do, and up until now it has been a good idea. I work in

small increments, and I have been perfectly willing to suffer longer curing

times in order to have a mix with a longer pot life. I work slowly and

carefully, and it is such a feeling of waste when the epoxy kicks off in the

pan before you can get it applied. And up until this project, I have

always been working in temperatures ranging from 80 to 90 degrees

Fahrenheit. But this project is different. I am going to use Epoxy

as glue for my butts, scarfs, and chines. I am also planning to

epoxy/glass all surfaces inside and out. But early in the week, we got a

cold blast and the nighttime temperature dropped down to the mid 30s.

Now the "user manual" that Larry sends out says I should maintain

temperatures above 70 F for a strong cure. On the other hand, the System

3 guy and others say that low temperature may slow down a cure, but that the

cure will merely resume as soon as the temperature rises. So this week

started out as an experiment and has been going well. Monday the

temperature was at it's lowest point, and has been rising slowly each

day. I have been applying epoxy and glass to the frames in the evening

by flourescent light. By morning, the epoxy is still tacky, but no

longer wet. I then move the frames out to a spot that will be sunny most

of the day, and by the time I get home from work the cure is hard enough to

handle and even lightly sand off the bugletts. I have had some trouble with

air bubbles, but nothing major. I am using the wet on wet method for the

first time on these frames. I find I actually use less epoxy this

way. The last time I tried this method, I waited too long, the epoxy was

too sticky and the cloth too light. Also rolling the cloth out

myself. I wound up with a bunch of ruined cloth firmly stuck here and

there with lots of wrinkles and ripples which could not be smoothed out.

I had to struggle to peel it back off, let the first layer cure to hardness,

and then lay new cloth over it. But with the smaller pieces of glass I

am using for the frames, and with the cooler night air, I have plenty of time

to place the cloth and smooth it before the first coat becomes sticky and

unmanageable. I sliced through my gloves into my fingers tonight on a

bit of hardened glass that I didn't trim flush with the edge of the

frame. Gotta watch that stuff--it's like a getting a papercut only the

edge slices much deeper much more quickly. I have coated every surface

of every frame with epoxy. I have glassed every plywood face of every

frame inside and out, exept the outside of the transom. I am going to

use the overlap from the heavier 6oz glass for the bottom to cover the transom

exterior. I felt a little blush on the surface today, and I think this

has something to do with the inordinate amount of fog/dew present during the

night/morning. Whereas I didn't get any earlier in the week when it was

colder. This seems to be a pattern with Raka epoxy. It blushes more from

humidity than from low temperature.

click

above to see Bill Sandifer's Crawdad at his minimalist boater website. This is

like a tadpole AF4!

November 4, 2001

The sides are cut and butt blocked. There was quite a bit of work in

marking and measuring, and it all occurred at ground level. So my knees

took a lot of abuse, my back hurts, and I have a massive headache. Still

it is wonderful to have those two sides laying flat in the "assembly

area" of the shed. I have been fortunate to be enjoying days in the

70s and no rain. I need about 5 more days of this to finish my epoxy

work--full days--not necessarily consecutive days. Hell, I wish it was

March already.

November 18, 2001

This weekend I finally went 3-D. I attached all the preglassed, epoxy

coated sides and frames. And Voila, she looks like a boat. It is

funny how no picture, no model, no shape drawn out on the dirt with a stick,

can entirely communicate the the reality of the boat shape. Or perhaps

that is a personal limitation of my visualization abilities. But in any

case, the boat appears "fatter" and less sleek than I

imagined. From what I can see now that it will be perfect for solo

onboard camping, and a very realistic hull for hauling camping gear and two

large adults. I am glad now that I did not build the AF4 Grande.

This will be plenty boat for my purposes. It is still small enough so

that I wouldn't hesitate to take it on a solo fishing trip, but with as much

room for gear and crew as I will ever need. If the lovely one develops a

new interest in onboard camping, and I get financially able to buy a larger

motor and trailer, I'll take another look at the AF4 Grande. I hope

someone else does before then, and takes some pictures with people in it for

scale.

I got the first lamination of the sheer wales on, and scarfed the pieces

for the deck clamps. But sadly I ran out of pine 1X4s before I ran out

of sunlight and good weather. I must acquire more tomorrow after

work. The 70° days and 50° nights are supposed to drop to 60 and 30 by

Wednesday. Drat it. I also need to get one of those round plastic

access ports for my vent in bulkhead 2. I've decided that that will work

well enough. I am still puzzling over how I can have windows that

OPEN. I really want this feature. On the other hand I am not

paying $100 each at a marine supplier for them.

So I am epoxying while I can. Next the deck clamps, cockpit coaming,

and final sheer wale lamination. Then the hinged door for the

compartment under the motor well. Then the deck beam. There was a snafu with

the pictures. The lab lost some of my negatives and didn't include

prints of others. And then the ones I do have are darker than I

wanted. I'll get a pix page up once it gets too cold to

glue.

November 22-25, 2001

Completed cockpit coamings, deck clamps, sheer wale, and added deck beam

and bow deck. I also flipped the boat by myself (a hairy moment that

was), and attached the chine logs with epoxy and screws.

November 29, 2001

Attached bottom with butt blocks with epoxy and screws. Yes!

Saturday, I will bevel the chines and glass the bottom.

November 30, 2001

Glassed bottom this evening, will second coat Saturday a.m.

December 1&2, 2001

Taped seams, second coat to fill weave of glass cloth. Sanded tape

edges. Bottom now ready for skids. Once again I am out of

lumber. Plus the holidays (and the lovely one) demand I snap out of my

obsession for a week or so.

December 9, 2001

My buddy, dp, suffered a setback, and his participation in our adventure is

now less certain. I hope he can overcome his pitfall, seize his

opportunity, and still make it to Georgia by next Fall.

December 26, 2001

The weather has finally turned. Tonight it is supposed to be in the

lower to mid 20's here. Today the high was 57°. I spent a little

time cutting out air bubbles, sanding, etc. The skids are epoxied on and

have been coated once (which was absorbed by the wood). Will have to

wait a while for warmer weather. I may spend a little time getting the

trailer in shape.

March 16, 2002

Somewhere in January I painted the bottom of the boat. I bought Behr

acrylic latex primer and paint. And applied it with roller. Now I bought

a 3 inch roller handle, but I had some longer rollers in the shed. So I

cut one down to fit, thinking to save a few bucks. Bad Idea. It

turns out that the fuzzies on the cut edge of the roller, came loose and

imbedded in the paint as I applied it. Not noticeable at first, but when

checking the dried paint I realized I had bumps and squigglies all over the

surface of my finish. First I picked at them, leaving exposed pocks in

the paint, revealing the primer underneath. Then I tried sanding them,

but in some cases, the fuzzies remained even after the surrounding protruding

paint was sanded away. What a mess. Ultimately I sanded the finish

nearly off and started over using the brush. Now it looks fine, but the

finish is not very hard yet. I am hoping that a few weeks of sunny days

in the 80's will take care of that. In the meantime, I have developed a

plan for revamping my trailer. I definitely want a board down the

center for walking on. I also have to add bunks and chisel off the

rusted split rollers that are on the trailer now. I have a lumber list

for the supplies. I am slightly worried because the wheels are 15 inch

truck tires, and the bunks will have to be higher than usual because the AF4

has such a wide flat bottom. The john boat fit between the tires, and

the v-bottom that came with it had enough deadrise to ride well over the

tires.

Also, I purchased a marine toilet. I bought a Thetford, bottom of the

line. It looks good. I haven't tried it out yet, though I did sit

on it in the store. The friend who was with me suddenly forgot she knew

me and vanished down another aisle. I get it home and I am showing the

lovely one. I demonstrate it's flushing, with some water and toilet

paper. It is all I can do not to take it for a real spin. I'm just not

used to spending so much for a toy I can't play with when I get it home.

The lovely one and I decided that for the boat, the 15ft cabin tent we have

is much too large and heavy. So we bought a 4 person (which is really

only a 2 person) dome tent. It is extremely light but is still large

enough for two air mattresses and gear. And it only cost $30 at WalMart.

I am very happy with this buy.

I have also purchased the plans for Michalak's Piragua 18. I think I

can cartop it for when the lovely one and I camp at state parks. I like

Jim's electric motor idea, but will get to that later. Just need

something light, easy to paddle, and big enough for two. I recently saw

an undecked Larsboat pictured on Jim's site, and it made me think some more.

But in the end, I still think the Piragua 18 will suit my needs

perfectly. It's not that I couldn't build a multi-chine hull if I wanted

to. I just haven't found the right one. I am hoping one day to

find a design nearly as simple as the AF4, but about 20' with some vee in the

hull. If not, I may actually take a stab at modifying the AF4 Grande

hull myself. But that is far in the future when I can afford a 25hp 4

stroke. Or who knows, the AF4 may handle the chop in the sound better

than I think. I do plan to try Max's idea about filling the anchor well

with water. With enough weight in the boat, I might just plow through a

rough chop at low speed. Probably not, but I'm gonna try it.

March 17, 2002

Okay, one more thing is bothering me. I painted only the very bottom

and chine logs, not the sides of the boat, because the sides still have screws

in them holding in the temporary frames. I want to leave the temporary

frames fixed in place until after I flip the boat and put on the decks.

But this will slow down my finishing, because I will have to fill the screw

holes with epoxy, then prime and paint the sides later. I guess this

doesn't matter that much. But there seems like there might be a shortcut

here, if I were smart enough to figure it out. Several great boating

weekends have already passed me by and I have still not flipped the boat

over. I must get my butt in gear. The gnats are gnawing, and the

yellow powdery tree pollen is dusting everthing, including my freshly painted

boat bottom.

March 22, 2002

Well, Me, Lovely, and a friend of ours (a young lady) from up the road

flipped the boat. We didn't have enough muscle between us, so we wound up

grinding one chine against the floor as we simultaneously turned the boat one

direction and slid it back the other way. It scraped through the paint

and the primer and slightly into the epoxy, but the fiberglass tape held up.

The boat cushion I put under the edge to protect it slipped out past our point

of no return. So I just listened to it grate and kept encouraging the

girls. Not a big deal, I'll touch that right up, etc. They WERE a great

help.

Next weekend I am going to see dp at his home in Tennessee. He is

converting to Catholicism and joining the Church. I'll drive up Friday,

stay the weekend, and drive back on Monday. It's an important

moment in his life (understandably) and he asked me to come, so. It'll

be good to visit him, even for two days. So this weekend is BOAT BUILDING

MANIA MADNESS. I'm puttin on my fiberglass proof mask and leotards and

kickin some serious boatbuildin butt. Come see what the Rav is cookin!!

(deteriorates into bad pro wrestling rap)

March 23, 2002

I got up around 9 am and made coffee and breakfast while Lovely slept

in. Then mosied out to the boat to survey the situation. First I

removed all the bracing sticks I temporarily screwed on before flipping the

bottomless hull upside down. Then there was some cleaning up to

do--there were COBWEBS I am ashamed to say. I spent a lot of time just going

over the corners and assessing the glue drips, etc. Then I removed the

drywall screws which were holding the skids on until the epoxy set, and I

replaced them with bronze ring nails. The instructions said that my next

move was to make glue putty fillets all around the inside where the sides and

bulkheads meet the bottom. I wanted to use fiberglass tape on the seams,

because it makes it easier to have a smooth fillet, but I had a problem.

The temporary forms were in the way. The instructions mentioned removing

the forms after the decks were temporarily in place. But could I get

away with removing them now? I decided that I would try to screw the top

board of the forward form to the plywood sides and then remove the bottom and

sides of the form, leaving the top crossmember in place. I began removing the

screws from one side of the form, thinking that the inward compression of the

gunwales would hold the form in place. But I was wrong, the form was not

in compression, after all, but in tension. When I removed the last screw

on the starboard side, the side popped away from the form about 1/2

inch. I was surprised, but I looked the shape over, and it seemed to

still have a nice smooth curve. So I removed the form entirely. It

looked good. So I sanded all the bumps and drips, vacuumed, mixed up a

batch of epoxy, and filleted the cabin all around. The taped seams

looked really good, and I decided that my skills had really sharpened since I

built the pirogue in 1998. Then the Lovely One came out to see what I

was doing, and to remind me that I was taking her to the grocery store.

So I cleaned up and went in. Going to the store, returning, cooking

supper, etc. used up the rest of the daylight. Somewhere around 8pm I

decided that I would go out and gaze at my beautiful boat again. I

reached up to throw the switch on the overhead shop light when the flourescent

tube suddenly fell out onto the cabin floor. I switched on the drop

light and looked. There in the sticky, yet-uncured epoxy fillets were a

million tiny fragments of broken glass. I mean millions and I mean tiny.

Each piece being between 1/8 and 1/4 inch square (well not really square, but

it gives you an idea of size). To pick them out of the goo would take

hours and tweezers. I spent about an hour doing just that. I had

some success scraping with pieces of cardboard and tongue depressors, but it

was a major bite. I finally gave up and went inside, thinking I would

figure out a way to deal with the remaining imbedded fragments after the

cure. I decided I could maybe pulverize them with a round stone, or use

grinder on the dremel tool or something. Anyway I was a little

discouraged and done for the day.

March 24, 2002

This morning I started at about 9am and began by making a list of things I

would do, in chronological order. Then I did them all 1. I vacuumed out the

cabin, and picked out most of the remaining glass fragments (the cure being

more advanced actually made it easier to pick out the pieces without taking up

a lot of gooey glue with them. 2. I sanded the bumps and drips off of

the cockpit sides and floor, and removed the temporary form in the cockpit. 3.

I filleted and taped the seams in the cockpit and ran a finger fillet all

around the butt blocks. 4. I mounted, marked, and cut the decks.

Then temporarily screwed them in place. 5. I removed the cross brace on the

deck . . er, coaming? and cut the extensions off flush. 6. I marked and

cut the circular hole for the vent in bulkhead 2 (I am using a plastic access

port for this). 6. I rounded the gunwales at the bow with the belt

sander. 7. I sanded the top of the sheer wales, to remove drips and

smooth any differences the between the two 3/4 inch laminations. 8. Then I

vacuumed out the anchor well and vacuumed the sheer wales and the top of the

chine logs. 9. Then I filleted and taped around the bottom of the anchor well;

this was a bit difficult to reach down in the tall narrow space, but I managed

by hanging over the side being careful not to get stuck. 10. I used the

remaining epoxy to seal a few remaining cracks between the chine log and the

sides, running a finger fillet down the hole length.

Everything looks great. Still left to do: Seal floors, glass decks,

paint exterior sides, paint interior, make and attach deck clamps, install

motor well deck, cut and install windows, add bow and transom U-bolts, Kleats,

plugs. Is that all? I am getting close to

finishing!!

March 25, 2002

Today I did get a half hour to look the boat over and check the status of

the epoxy cure from yesterday. I looked at the deck tops again, and I

just can't help myself. I know they are going to check, and I can't live

with it. I'm ordering 6 more yards of cloth from Raka to glass the

cockpit floor and the decks. These are areas which will take the most

abuse from the sun. Plus the glass weave on the cockpit floor, without

fairing will provide a strong nonskid surface (maybe). Especially as I may

wind up storing this boat outside. This will add a couple of weeks to my

building schedule, but will be worth it in the long run. I just reread

my skimmer page, and I am reminded that I need to take a Saturday to go

fishing sometime soon.

March 27, 2002

This afternoon, I had little daylight time to accomplish anything (the

breaking of the fluorescent bulb having crippled my previously inadequate

lighting), so I just wound up hanging out with the boat and thinking ahead. I

put a few milk crates in the cabin to approximate the battery, supplies, and

toilet, and then lay down. First thing I notice is that there is JUST

enough space for me to stretch out comfortably, another person sleeping in the

cabin would not practical. It could be done, but all the gear would need

to be moved into the cockpit, and it would still be "cozy" to say

the least. And as Lovely will testify (and as evidenced by her

collection of earplugs) I snore horribly. Good news is that the much

discussed "sharpie slap" should be a distant drowned-out second in

nighttime distractions aboard my boat. So I think IF Lovely comes with

me, and IF we wind up sleeping aboard instead of tenting ashore, THEN I might

sleep in the cockpit. Now I am a few inches longer than the cockpit, but

it is plenty spacious and I can do a slight fetal curl and sleep in reasonable

comfort--I think. Second thing I noticed was the butt block in the cabin

seemed to get larger and sharper the longer I lay there. I flashed on my

"princess and the pea" camping experiences, where I wake up bruised

and battered, break down camp and tent looking for that monstrous, spiky

meteoroid I slept on--only to find an acorn. And my experience has been

that no reasonable amount of foam (of thickness one might haul a-camping

anyway) will not significantly deaden the feel of a root or other irregularity

under your sleeping bag. In fact, until recently when Lovely and I camp

tested our first set of air mattresses, we didn't know what we were

missing. Lovely slept great which is unusual for her. I always

sleep like a log, but this time I woke up feeling refreshed and rested instead

of abused, in fact I actually went back to sleep for another hour. So

some type of air mattress will be a MUST for sleeping across those butt

blocks. The ones we have are "twin," but they are still way

too large for sleeping aboard. We'll have to seek out an inflatable

float of the right proportions.

I also got to thinking about the lighting, battery power, etc. I am

sorely tempted to just skip the whole electric thing and use two lanterns for

cabin and anchor lighting. Pro's were: Via cigarette lighter socket a

Recharging source for mobile phone; Electric cabin lights; Electric

anchor light; Power for small fan (it gets hot in South GA) and other small

appliances; Battery weight forward for better trim. Cons: Battery weight

increases overall weight, Battery takes up space in cabin, any wiring

performed by me will look less than aesthetic. I don't know what the

downside of propane or liquid fuel lanterns might have as cabin or anchor

lights, but I think I will try them first before messing around with

batteries. My phone holds a charge for at least a week as I only turn it

on to make short calls and immediately turn it off again, and I can recharge

it anywhere with shore power or a 12v battery. Weather radio, cassette

player, and small reading light, can be powered using conventional

batteries. The fan may not be a necessity if I have good ventilation, or

it might not make a difference on a hot night anyway--yet to be

determined. I think I'll have to give it a go without electric for a

while and see what I think.

I checked the store for the AF4 building photos today, the day they told me

they would be ready. They didn't have them back yet, got defensive, and

insisted that I was there a "day early". I was nice and didn't

argue, but I'm nervous since they lost my negatives last time. I gotta

go digital or find a better photo lab.

Leave for dp's the day after tomorrow.

April 2, 2002

Back from dp's. No time for the boat until this weekend. But

daylight savings should make more weekday work possible starting next week.

April 6, 2002

Today I accomplished quite a bit. The sloping top of bulkhead 10

meets the sides about 1/4 inch high, so I ground the corners down with the

belt sander. I also used the jigsaw and the belt sander to trim the

slightly oversized deck panels to fit. I measured and cut the window

openings, marking them first on the outside, then, using a small bit, drilled

holes at the critical points. Then I went inside with a pencil and

straight edge and connected the dots. I like the looks of the square

windows per Jim's plans, rather than round or oval ports. But I did

round the corners well to help prevent water collection. Then I sanded the

openings, a few epoxy burrs I missed here and there, and the epoxy filler I

put over the nail heads in the floor. As I had removed drywall screws and

replaced with nails, most of the heads were set below the surface and needed

filling over. I measured and cut the deck beams. I took a 1X4 the

same width as the 2X4 and screwed it flat to the back end of the deck

beam. Then I went to the front end of the deck beam and raised the

unscrewed end of the 1X4 an inch and screwing it in place. Then I just

set my table saw fence at 3 1/4" and tilted the blade 6 degrees (for the

bevel) and ripped it through. Remove the screws and the 1X4 and

Viola. The deck beam 2 1/4" in front and 3 1/4" in back with a

6 degree bevel. It was easier than I thought. I dry fitted the

deck beams and decks, then removed them and glued the beams to the decks with

PL premium and drywall screws. I used a tube I had still in the gun

since November--it was still good much to my surprise. I had simply

wrapped a little piece of duct tape over the tip. I had to push a little

hard piece in the tip back into the tube with a bamboo skewer.

Afterwards I epoxied 6 oz. cloth onto the deck tops. I vacuumed the tracked in

sawdust and dirt from the floor of the cabin cockpit and motor well. I

rolled out and cut cloth for the cockpit floor. Then I painted a coat of

epoxy only on the cabin floor and motor well, epoxy and glass in the

cockpit. I had wanted to glue the kleats that support the motor well

deck, and cut the deck pieces, but I had to drive the lovely one to the

grocery and eat a barbeque sandwich with slaw. Plus my knees and back

were killing me. I slipped on rain slicked concrete and fell on my hands

and knees at dp's, and I'm still not quite right. I've been a flatlander

for so long now, I forget the importance of a good shoe tread.

I am so close to finishing now, I am beginning to think in terms of

"what is left to do" rather than "what is next." Tomorrow

will be largely interrupted by a trip to Wal-Mart, Home Depot, and buying my

father's Oldsmobile. But I should be able to get a few hours in before

and after.

April 7, 2002

Got less done today than planned. I installed the sticks (or

"flanges" on which the motor well deck will rest. I got a

little confused about the measuring of the motor well deck. The plans

show this part (put together from two) in the nesting drawing cut from the end

of piece of 1/2" ply, but no dimensions. The piece is cut into

using a diagonal across the center of unknown angle. I guess Jim figured

this was too elementary to detail, and likely to be a cut-to-fit operation

anyway. But it sort of threw me. Sometimes my brain trips over

even the simplest steps (like whether or not setting your clock back takes

away or adds time to the day). When this happens the more I think, the

more tangled and obsessed I get. This is what happened with the motor

well deck. I understood that the diagonal cut was a way of having a the

deck wider than the 48" sheet forward and less aft. My brain choked more

on the angle of the cut. I went inside did something else, then sat down

with a pad and ruler to approach the problem earnestly. First the width

at front was 49 1/4" and the width at the transom (without the corners

chopped out) would be about 46". So erring on the side of

caution--I can always trim down-- I decided that I needed to slope my cut to

decrease 1 1/2" over the 20". So I settled on 24 3/4" and 23

1/4" from both ends. These will be much easier to fit and trim BEFORE

joining the two halves.

I rolled another coat of epoxy on the cabin, cockpit, and motorwell floors,

more on the topside of the decks as well to fill the weave. Mixed a

little leftover epoxy with wood flour and filled any cracks where the flanges

joined the motor well. The Lovely One promises to put the decks in the

sun tomorrow midday. I wish I could roll the whole boat out, as the

epoxy cures so much quicker in the sun. But I can't yet. Max suggested

how to get the boat on the trailer (once I get the trailer ready) and it seems

so simple now.

The trailer's previous owner installed auto tires and wheels, on the hubs,

which is why I am having to build the bunks up so much, but I am thinking I

might save some trouble if I can just switch back to smaller wheels.

We'll see if the lugs are too rusted, etc. and compare the cost. My list of

Things Yet Undone shortens. My father suggested a boat name today which

is the best one yet, but still . . . I continue to search for the perfect

swamp-boy-river-boat name.

April 8, 2002

Daylight SAVINGS!! I LOVE IT!!! It seems like I had 3 extra

hours to work this afternoon. I cut the motor well deck according to my

measurements and it fit more or less. I only had to cut out the corners

and shave 1/2" out of the middle. I connected the two halves with a

1X4 and PL Premium, and epoxied the underside (tomorrow I'll flip and do the

topside). I also epoxied the underside of the cabin decks. When I glue

the decks in place, there will be a little sanding of edges and some sunken

screw or nail heads. This will require a little epoxy touch up.

But other than that I will be through with the epoxy on this boat. When

I'm finished I will have used four gallons total (yerk!). I think

building in cooler weather was partially to blame; I notice getting a lot more

mileage out of a pint of epoxy not that the weather is warm. On the

other hand, the wood seems to soak up more now too. I don't know. I've

never used more than 6 quarts on a boat before, but this is a bigger boat by

far than any I've built, with a lot more surface area.

Still no name...

April 14, 2002

Epoxying is officially finished (well except for swabbing the Motorwell

drain holes and maybe some fairing where the angled 1/4" side decks meet

the flat 1/2" front deck). The recent epoxy application has been on

decks, so I commenced to prime the inside and outside of the boat. I

painted the sides up to the sheer wales. But I was out of paint.

Now why didn't I buy the light color for the inside when I bought the hunter

green? I'll get it tomorrow. Still no name...

April 15, 2002

Bought paint today. $23 a gallon. Now I remember why I didn't

buy both gallons at once. I bought some stainless u-bolt bow eye thingys

for the bow and transom eyes (I'm hoping they are substantial enough for the

lift at the marina). I bought some cheapo bow chocks, too. I discovered

a "boaters world" near home depot. I was both entranced by the

stuff and repelled by the prices. The guy in front of me in line was

special ordering some fishhooks out of the catalogue. While the inept

clerk went for help, the guy calls a buddy on a cell phone to tell him this

kind of hook can be had. Then they finally get back and ring him

up. "That'll be $86.95, sir." "Will they mail them

to my home or will I have to come back here to pick them up?"

"They'll be mailed here, sir," taking the signed slip and giving him

the receipt. "Just bring this with you when you come to pick them

up. It'll be about two weeks." Suddenly the clerk's attention

turns to me and my plastic chocks and u-bolts. I realize my mouth is

hanging open. I hear you can take a safety pin and bend it to make a

nice fishhook in a pinch. I've seen barbed twigs and bones in Native

American museum displays.

Still no name . . .

April 26, 2002

I absolutely hate painting. I generally suck at it too. You

could hand a typical 10 year old a paintbrush and let them have at it and the

results would be superior to my best efforts. If I use a brush, it takes

me 4 or 5 coats to get a good coverage. I don't even want to talk about

what happens when I use rollers, foam, etc.. Until I began building

boats, I had managed to avoid painting anything for a decade or so other than

spray painting some patio furniture.

This boat has really soaked up some paint. I have now applied 1 1/2

gals of primer and 2 gals of paint and I'm still not done.

I have started on the trailer, and have spent nearly half the cost of a new

trailer already. Lumber, rollers, galvanized hardware, wire, carpet,

glue, etc.. I finally have the kinks out of my plan, and am short only a

few bolts of having all the materials I need for realizing it. I should

complete it this weekend.

I have a few other things to do on the boat. I still don't have the

motor well deck screwed and caulked in. I don't have the window glass

cut or installed. I don't have the round access port that I am using for

a vent installed, nor have I installed the handle and chain on the

inside. I haven't finished painting the decks, one more coat there, in

the cockpit and the anchor well. I haven't drilled and installed the bow

eyes and transom eyes, cleats, and other hardware. I haven't installed

the door over to the storage area under the motorwell. I haven't built a

tiller extension, and I am back to square one on the bimini top--the freebie

from my friend didn't materialize.

May 3, 2002

Okay, so the trailer is being a real pain in the butt, but it is more or

less complete short of tacking on the carpeting. I finally got the bunks

mounted, thanks to some advice and photos from Max and others at the Michalak

e-group. Also, some valuable information was acquired by pulling over to

look at boat trailers parked in yards, the ones at the local marina were less

instructive, because they were all nearly new and built for the vee

hulls sitting on them. Next time I will consider a new trailer part of

the required expense for building a boat.

Today I saw a 1992 15 hp Yamaha in "excellent condition" for sale

in the paper for $650. I called the guy from my job and made

arrangements to see it after 5 pm, but I was pretty much decided on buying

it--I even called the Lovely One to warn her that her boat crazy husband would

be coming home poorer and happier. When I called him at a quarter 'til for

directions, he told me he had sold it already. I was soooo

disappointed. I could kick myself for not cutting work and running right

over there, but I had fairly critical things going on at work today.

Damn, I'm still having a hard time letting go. I have been checking the

classifieds without fail for over a year now for just such a deal. When

I saw it, I thought "that's my motor, just in time!" But it

turns out that it was someone else's. Oh well.

I received the $11.14 u-bolts from McMaster-Carr today (total $27.85 with

shipping), and drilled the holes through the motor mount board and the 2X4

transom framing. Way too expensive, but now I don't have to flash on

Max's splitting 2X4 nightmare scenario every time I launch. Sometimes I have a

real internal struggle between being smart and being cheap. I like it

best when I can do both at once.

I have screwed and caulked the motor well, and painted the perimeter.

I have cut and installed the window plastic. I cracked it so many times

I began to fear getting two window sized pieces out of the 36 X 48 sheet I

bought. The drill cracked it, the sabersaw cracked it, the grip clamp

cracked it. Argh! The window framing on the inside was also a

disaster, and I missed the shear wale and drove a screw right out through the

outside of the hull. But with filler and glue, I have managed to hide

most of my errors. I suspect the cause for my difficulty was the

thickness of the plexiglass (Home Depot did not have the specified thickness

except in large untinted sheets priced at over $60). I installed the

access port in the ventilation hole. I still haven't found a small

galvanized handle for opening from the inside and attaching a small chain.

Decks have been painted. I may give the cockpit one more coat, now that

I have little further reason for climbing in and out of it. Have yet to

install the bow eye (am thinking of waiting until I get it on the trailer) the

stern storage area door, and cleats.

Still no name.

May 7, 2002

A few days ago, I attempted to get the boat trailered using Max's method of

raising up the front end, blocking it back at the midpoint, and winching the

trailer under the boat. Right away, I had a problem. The skids I

had measured at the transom as being 31 inches wide from outside to outside

were 31 3/4 inches wide at the bow. Some measuring of the bunks revealed

that somehow in my tightening and adjusting I had managed to decrease the

width between the bunks to be something just a hair under 31 inches. The

story gets stupid where I didn't really believe my own eyes, because I had

measured so many times and just knew it would fit. So I continued with

the lunacy of trying to load the boat long enough to scrape paint of the skids

and imbed carpet fibers into the paint. I am concerned about losing the

paint. True I put it under extreme duress, but I suspect some might have

rubbed off anyway, and the way the fibers from the carpet stick into the

surface leaves a fuzzy nasty surface to paint over. And this particular

paint is now over four months old! Next time I do this I will paint the

boat using thin multiple coats, with a roller, not a brush. I will paint

it in the 90 degree sunshine and let it bake on.

Anyway I had to take the boat back off the trailer ( a whole 'nother

crisis), take the trailer back apart, drill new holes in the galvanized frame,

and reconstruct the bunks and the separating frames. I busted more

knuckles, etc. This weekend I should have time to retrailer the

boat and get it out in the light to take some decent pictures.

May 12, 2002

Yesterday I retrailered the boat and got it out into the sun. I shot

a roll of film on it from every conceivable angle (trying not to get too much

redneck yard junk in the background). But I still have a problem with

the way the boat sits on the trailer. Because it rides so high, to clear

the auto sized tires, the bow is nearly 17 inches above the trailer

frame. Plus it lacks support up front, so it rocks forward raising the

transom off the bunks nearly 5 inches. The rollers forward I raised as

high as they will go, barely make contact now, when raising the bow up so the

transom is flat on the bunks, the rollers are nearly 4 inches below the bottom

of the boat. I stuck a little stool (actually it is one of those

carpeted cardboard cylinders sold as Kitty Condos which I have been using as a

stool) under there, just to get a look at where I need to be. I finally

decided to do something simple and build up a solid chunk of wood from 2 X 8

scrap ends, then affix angled bunks on each side, and just wedge the sucker in

there This also allows me a little adjustment should I choose to adjust the

bunks a little lower later on. I got the chunk with bunks built, but I

need to round the forward ends, tack on the carpet, and build a small platform

across the front of the trailer frame to set it on. I think I will tack

some 1X2 around chunk, so I can lift it out, but once in place it will not

slide around.

Other things I've done but failed to mention. Bow eye, mailed off

boat registration (could have done that months ago), patched a place on one of

the skids where a nail punched out a chunk of wood after I flipped the boat

over and was nailing from the inside. I didn't see it until I was trying

to get the bow up high enough to get the trailer started under it. Installed

the cover over the rear compartment. Yeah, that's about it.

Still no name.

May 14, 2002

Okay, the trailer is done. I still don't have the kleats, slot top,

and tiller extension done. So the boat is pretty bare looking, but I

will launch regardless this Saturday. In the light of day, one can see

my lack of spit and polish finishing, but I just squint and step back a few

paces, and she's a beauty. My new PC doesn't work with my old flatbed

scanner, so I won't be able to post pix until after the launch. I'm

giving up on the name until one suggests itself strongly, perhaps during an

excursion. I must acquire tie downs, etc. There is a certain

untouched beauty to it now, without gear and the necessary screw eyes, hooks,

and bungies. But already I have tracked up the floor with footprints,

etc. My primary concern regarding the launch is the drain holes and

plugs. They are the obvious place for leakage if there is to be

any. Also I worry about loading and unloading. But I have picked a

freshwater location for the splashdown, and have decided that I will submerge

the axle if necessary to get the boat off and on without scraping or

damage. Gotta get the motor ready. Nothing much else to report

until after the big event. Wish dp were here to see it.

May 15, 2002

This afternoon purchased tie-downs, etc. for the transom, bow and a strap

across the middle. Looks extremely secure to me. I forgot to buy

PVC, DOUGH! I need larger than the 1 1/4 inch PVC I have now.

Saturday looms closer.

May 18th, 2002

Thunder and lightning from noon on. If I believe the weather forcast,

I will not launch at all this weekend.

May 26th, 2002

IT FLOATS! She is an incredible craft! Being somewhat socially

awkward I found myself a little overwhelmed answering questions

about the boat at the overcrowded ramp and park. People on the water

even shouted questions and compliments at me as I chugged past. The 8HP

is plenty of power for my intended use, but I could not get her to plane.

Except for a 15lb river anchor forward, the hull was more or less bare, but I

had some friends and family show up and I never had less than three people on

board. I had rigged a tiller extension, but I didn't need it with all

the passengers wanting to ride standing in the slot. I wanted to try her solo,

but I ran out of time. Plus the water was insanely crowded with holiday

boaters.

But later that evening, in the solitude of my back yard, I loaded my tent,

porta-potty, lanterns, camp-stove, air mattress ($1 kid float from Dollar

General), sleeping bag, jug of water, cooler, etc. on board. I tied a tarp

over the slot. Then I snagged my copy of "The Esoteric World of Madame

Blavatsky" and crawled in for the night. The cabin would not sleep two of

my size in any but the most desperate (or perhaps intimate) conditions--and

only if all the gear were set outside in the cockpit, even then. But two

people could easily sit comfortably inside for an hour or two waiting for some

bad weather to pass. One of the miniature kerosene lanterns (burning lamp oil)

I bought at Fred's was plenty light to read by. I slept comfortably, but awoke

feeling a little rough about 7am. The boat was tilted up much higher in the

bow than would be normal on water, and there was no gentle rocking, soft

slapping of water on the bottom, or crisp sea breeze. So I had to use my

imagination.

Anyway, I plan to experience the real thing soon, perhaps this weekend. I

finished a proper cover for the slot top (which required sewing, cutting PVC,

and application of velcro. I still need to find 1/4" bolts long enough

for the stern kleats. I installed the USCG required fire extinguisher and air

horn. I wait for my registration numbers to come in the mail any day.

June 3, 2002

I forgot to mention, the boat has a name. It will be called the Jubal

Edisto. It's an inside story, but I think it suits just fine. I am dying

to go overnighting, but I have major household construction in my immediate

future, and doubt to have more than a day trip in the next 4

weeks.

Launch Pix still in development.

Back to Top

Because I am a big guy who snores, because my buddy is also, uh, big for his

height, and because the AF4 cabin is, in Jim's words, "Cozy," we will

not want to share the cabin space for sleeping if we can avoid it. We will still

want to respect each other in the morning. The alternatives are to tent camp

ashore whenever possible, and to develop a tent or cover for the cockpit.

Now in these parts we are plagued by a variety of gnat which gnaw you to death

in short order, and also, like much of the South, are subject to large mosquito

populations. Plus, it gets downright muggy at night. So i am looking

into several possibilites.

One is to buy a bimini top and drape with mosquito netting and/or polytarp at

night.

Two is to design some type of quickly erected structure with a polytarp,

cover which can be disassembled and stowed when not in use. I have toyed

with several of these. Select below to see rough sketches

Again I have taken Jim's advice seriously, and will develop a polytarp cover

for the cabin slot using the PVC bows he describes in his essay

on hatches and vents.

My friend with the Whaler got a different boat. She's giving me the

bimini from her Whaler. It may well be too wide, 59 inches, but hopefully

I will be able to do something with it. I found exactly what I need, were I to

buy new for $119 mail order--basically a two frame budget bimini made for your

typical aluminum john boat. Either way, acquiring a commercial top should

be within my grasp. Then I can see what I can do with some tarp and some

mosquito netting for closing the cockpit in entirely.