Online Tour

Page 2

CLEVELAND MILLFEST 2013 AT CLEVELAND ROLLER

MILL MUSEUM

Date: Saturday (August 31)

& Sunday (September 1) - Schedule

|

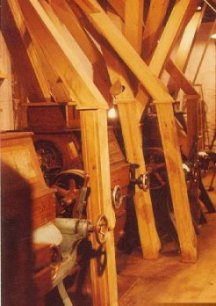

The wheat seed would begin the grinding

process by going through the first of the roller mill stands

(left). This mill stand contained the "break"

rolls (very rough) that would start the grinding process by "breaking"

the bran outer hull of the wheat and subsequent smoother rolls

would continue the grinding until all possible flour, bran, and

germ was extracted. The long vertical wooden items in the

foreground are gravity chutes, part of the semi-automatic transport

system used to move wheat and flour around the mill. Elevators,

consisting of continuous looped belts with small buckets, would

dump the product into the gravity chute, where it would slide

down to the next machine or bin. |

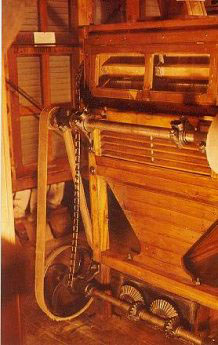

| The box like object in the background

is one of the huge sifters of the "four box sifter"

and contains large horizontal screens from top to bottom.

The boxes are suspended from an eccentric shaft and the motion

of the shaft when operating, causes the boxes to shake and sift

flour through their screens. The lower half of each box

contains controls to allow flour to cross the screens or bypass

them in order to process the specific grade of flour the miller

wanted. The machine in the foreground is a "plan sifter"

which, besides sifting, also contains a fan to blow off fine

dust. Some of the original belts used to run the mills

machines were made of leather and the museum still maintains

those leather belts that were left on the machines when the mill

ceased operating. |

|

|

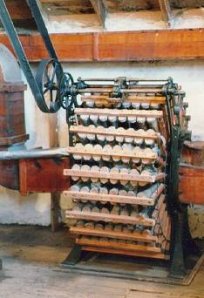

A strange looking machine indeed.

The sock duster had one duty only, to collect dust. Fine dust

from flour milling can be very hazardous, not only to the health

of people breathing it (it was common for early millers to have

lung congestion), but also because in quantity, dust is a deadly

explosive. Attached to the horizontal piece of wood on

each row was a series of eight cone shaped socks. Dust

was blown into the machine by the two shafts, one on each side

of the duster, and the small metal pipe on the left. The

dust would be trapped in the socks and then later extracted in

bulk and removed. |

| Back

| Home |

Copyright 2013 Historic

Mora Valley Foundation

|