Figure 1 Initial Version of Amplifier with Differential Negative Feedback.

Daily Activities Log.

This page last updated Tuesday, November 16, 2021.

in, Remote sensing negative feedback.

What Happened to the Vacuum Tube Curve Tracer?

The long article which has been on this page for some time has now been turned into an equipment review. See the "NEW!" box on the front page.Case Closed.

The equalizers Article.

This article will soon be removed from this page. A condensed version has been added to the equalizers article. The parametric equalizer which was breadboarded will remain on the breadboard for a few more days in case anyone would like to see some additional measurements. Now is the time to ask because the breadboard will soon be disassembled and the article on this page will be deleted.Case soon to be closed.

This is my daily log page. It is what web users in their never ending assault on the English language have named a blog. I hate that word and that's the last time you will see it on my site. Instead of taking up bandwidth on the email list I will post my activities here so those who are interested can keep up and those who don't care don't have to be exposed to my more mundane writings, ravings, and rantings. I will report on things I am doing that may or may not become a part of the permanent site. Entries older than a certain number of weeks or months will be deleted. I haven't decided as yet on how long things will last here.I often run projects in parallel so I won't jump from one to the other. At the beginning of each project there will be a centered heading with the title of the project followed by left justified dates for each entry concerning that project. The centered headings will help you jump from one project to the next. The date below the centered title will be the date I start a project. I will enter the entire project under that date in order going forward in time. When a project becomes mature it will either be given a page of its own on this site, or will be deleted as not important enough to warrant that honor.

HOME.

Remote sensing differential feedback.

Tuesday, November 16, 2021.

I am intrigued by the idea of remote sensing differential feedback in an audio amplifier. The idea is nothing new to me because I have known about power supplies in which provisions have been made to allow the feedback control circuits in the regulator to sense the voltage at the load rather than at the power supply terminals. I suspect applying this concept to audio amplifiers may be fraught with unexpected problems particularly as the speaker leads get longer. But I feel compelled to do some testing. My first step is to simulate the circuit. The schematic diagram below is one I developed in LTspice to test the concept.

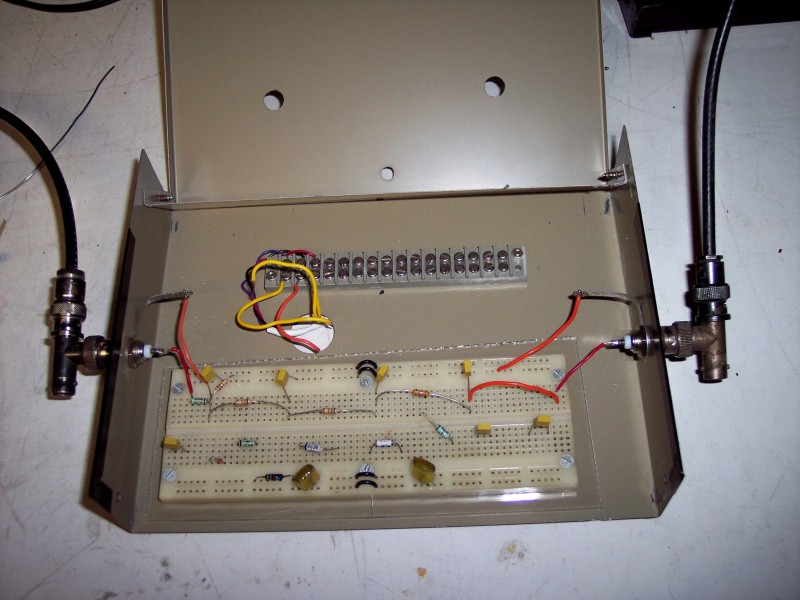

Figure 1 Initial Version of Amplifier with Differential Negative Feedback.

Figure 2 Time Domain Response of the amplifier to a 1 kHz Sine Wave..

About the Voltages.

Using tube manual voltages I couldn't get tube manual output power. Since this is a simulation I can increase the voltages without fear of burning out anything. The 6550 model must not be exactly right.As shown the amplifier requires 20 volts RMS for 50 watts output into 8 ohms. For high accuracy of gain it needs to be driven from a source with an output resistance of 1 or 2 k ohms. An amplifier with a low output impedance and a gain of 20 or so would do the job. If I were to build such an amplifier I might pare it with a preamp that will output 20 volts RMS without appreciable distortion. That means I could build the power amplifier as shown.

To Be Continued.

Finishing up the Equalizers Article.

Thursday, July 22, 2021.

When we last left our story King and Sargent Preston were searching for the lost little boy. Oops? That's something completely different. Now let's see. Where was I? Oh yes, I remember now.I was designing a high gain amplifier that is required to make an equalizer work. That would be simple if this were the Fun With Transistors site. Even if I were restricted to discrete transistors it still wouldn't be all that a big deal. But I consider ICs to be just a different way of packaging transistors so there is no need to start a fun with integrated circuits website. However this is the Fun With Tubes site so the amplifier has to be constructed around vacuum tubes.

Note: After this section is finished, an edited version of it will be appended to the equalizers page thus completing it.

Friday, July 23, 2021. The Amplifier Designed by Circuit Simulation.

LT spice won't give you circuits out of the blue. You have to have some idea of what you want to do and I did.

- Even though it would be AC coupled it had to behave like an op amp so a differential input was a must.

- It had to have as much gain as possible with the minimum of tubes.

- Not only did it need high gain but bandwidth that would cover the audio band with a little to spare on each end.

- It had to be stable with feedback down to unity gain and even below.

- It must have a relatively low output impedance.

To satisfy number 1 a long tail pair with a current source in the cathodes seemed to be a natural. Especially since I have had plenty of experience with that particular configuration. A 12AX7 seemed to be the first choice because high gain was needed here.

To satisfy 2 and 3 a cascode amplifier came to mind. It can have more gain than a pentode without the division noise and with very little miller effect. In a cascode transconductance is where it's at and of all the 12A_7 tubes a 12AV7 has the highest.

The fewer stages an amplifier block has the easier it is to compensate on the high end. On the low end compensation gets easier if the number of RC coupling networks is kept to a minimum. I decided to try direct coupling from the long tail pair to the cascode amplifier.

Number 5 is easy, a cathode follower. Because the top plate of a cascode amplifier is at a higher voltage than the heater to cathode breakdown of most tubes, an RC coupler would have to be inserted here. For the follower I decided to round up the usual suspect and use a 12AU7. The other triode can be used in the other channel.

As it turned out I had to limit the gain to get enough bandwidth. This was done by reducing the resistance of the cascode's plate load. That gave me a good gain and bandwidth both of which I could live with.

Here is my starting version of the amplifier with the parametric circuit connected.

Figure 18 Initial Version of Parametric EQ with Tube Amplifier.

Saturday, July 24, 2021. The Optimized Circuit.

The initial version worked in simulation but there was a nasty 9 dB peak at about 2.5 Hz. A peak in this frequency range can greatly amplify turntable rumble and lead to a rather unpleasant sound. Even if you have sold or given away your LPs and turntable you probably have some tapes of some much loved LPs that were never released on CD. They will have rumble recorded into them and the last thing you want to do is boost it. The infrasonic peak had to go.The simplest way to find component values that make an amplifier stable down into the infrasonic region is to make all coupling circuits time constants, except one, ridiculously long and the exception very short. Then you adjust the short one to get the frequency response you want. Next you work on each of the long time constants, one at a time, and make each one as short as possible without significantly affecting the overall frequency response. The long time constant circuits to be adjusted are C4 x R8, C5 x R5, and C10 x R25, or C10 x R11, but not both. All of this is much easier in a simulation than it is on the breadboard. (Note: When feedback is applied R25 is changed to 1 megohm and the feedback resistor is 10 k ohms. This resistor looks like a load to the amplifier and must be taken into account during the design process.) The one short time constant is C1 x (the effective resistance of R9). The effective resistance of R9 will be about 8 times its actual value of 100 k ohms. This is explained in the textbook and also on other pages on this site. Below you will find the updated schematic diagram of the amplifier alone with a plot of its open loop frequency response with the main points of interest called out in the table following the graph.

Figure 18 Final Version of Tube Amplifier.

The graph and table below can be obtained without slinging any solder.

Figure 19 Open Loop Gain vs Frequency of Figure 18.

Points of interest as picked from above graph using the cursor. Point Name Frequency (Hz) Gain (dB) Phase (°) Lower Gain Margin 0.2882 -16.67 0.0 Lower Phase Margin 0.9115 0.0 -47 Lower Half Power 365.8 52.10 -134.9 Peak Gain 948.4 55.12 -179.7 Upper Half Power 2.492 k 52.10 +134.7 Upper Phase Margin 1.610 Meg 0.0 +90.87 Upper Gain Margin 48.98 Meg -33.90 0.0 Monday, July 26, 2021. Adding negative feedback.

Many audiophiles would either laugh or cry at the frequency response curve. This even though the amplifier they love to listen to probably has a similar open loop response. What matters is the closed loop response, that is with negative feedback connected. So let's connect some up and see how it simulates. The easiest to understand is unity gain which is 0 dB. Here are the schematic and frequency graph.

Figure 20 Graph and Schematic of Tube Amplifier Set To Unity Gain.

Mid Band Gain = -0.03 dB.

Lower Half Power, f1 = 776.2 millihertz.

Upper Half Power, f2 = 743.3 kilohertz.

Minimum Gain at Low End = -9.24 dB @ 295.1 millihertz.

LTspice provides a means by which feedback can be connected without drawing a line half way around the circuit. The two points which are labeled "OUTPUT" are treated as connected together. Note that R25 is now 1 megohm and the load now consists of R11.

The extreme low frequency gain going back up to near zero can be accounted for. As the open loop gain drops off at the low end there isn't enough to support unity gain and the closed loop gain begins to fall. The open loop gain eventually gets so low that the amplifier becomes irrelevant. Signal is passed from the generator through R12 then R11 to the output. At frequencies lower than shown on the graph this becomes unity.

Wednesday, July 28, 2021.

We see in figure 18 that the peaks at mid band and high band go from -12 to +12 dB. Let's test our amplifier at plus and minus 10 dB and 20 dB to see how well it is likely to support the parametric circuit.

Figure 20A Closed Loop Frequency Response of Tube Amplifier.

Mid Band Gain = 9.94 dB.

Lower Half Power f1 = 2.238 Hz.

Upper Half Power f2 = 239.9 kHz.

Minimum Gain = 6.60 dB @ 295.1 millihertz.

Figure 20B Closed Loop Frequency Response of Tube Amplifier.

Mid Band Gain = -10.01 dB.

Half Power f1 = 436.5 millihertz.

Half Power f2 = 1.514 Megahertz.

Low End Peak = -8.45 dB @ 1.000 Hz.

Low End Minimum = -14.65 @ 288.4 millihertz.

Figure 20C Closed Loop Frequency Response of Tube Amplifier.

Mid Band Gain = 19.83 dB.

Half Power f1 = 7.244 Hz.

Half Power f2 = 95.50 kilohertz.

Low End Minimum = -5.62 dB @ 301.00 millihertz.

Figure 20D Closed Loop Frequency Response of Tube Amplifier.

Mid Band Gain = -20.02 dB.

No Frequency is 3 dB down from mid band gain.

Half Power f2 = 2.042 Megahertz.

Low End Peak = -17.59 dB @ 812.8 millihertz.

Low End minimum = -22.62 dB @ 281.8 millihertz.

Thursday, July 29, 2021. Now for the Parametric Circuit.

Figure 21 Parametric Circuit with Tubes.

With the original circuit there was a peak below 1 Hz. Changing C10 to 220 uf knocked it down.

Next step, build it on the breadboard.

DC comparison.

The schematic below is the amplifier as constructed on the breadboard.

Figure 22 Schematic of tube amplifier.

The alteration in the cathode of the cascode is totally practical. I don't have any 470 uf 100 volt capacitors. But I do have two 1000 uf 50 volt caps. So I made a slight modification to the circuit and the tube will never know the difference. For the DC measurements in the table below I grounded both inputs of the amplifier. (spoiler alert), Later when I ungrounded them I found that I had built an oscillator.

Figure 23 Photograph of amplifier built on breadboard.

LTspice Breadboard Tube Vk (Vdc) Vg (Vdc) Vp Vdc) Vk (Vdc) Vg (Vdc) Vp Vdc) U1 12AX7 0.7125 0.0 72.98 0.524 0.0 71.5 U2 12AX7 0.7125 0.0 72.98 0.524 0.0 74.3 U3 12AV7 75.07 72.90 131.7 77.9 74.3 133.4 U4 12AV7 131.7 127.5 245.6 133.4 128.3 247.6 U5 12AU7 17.17 15.61 105 16.45 14.95 107.1 Note:

In LTspice High B+ = 255 Vdc. On the Breadboard High B+ = 257.7 Vdc.

In LTspice B+2 = 208.0 Vdc. On the Breadboard B+2 = 207.1The results presented in the table are really very good. In general the rule is don't expect accuracy any better than 10% when dealing with tubes. The values are considerably better than that.

Sunday, August 1, 2021. AC Comparison.

When setting up the analog discovery for some really serious work I found that when the signal generator is set to 10 millivolts and below there is a great deal of noise on it. In fact there was almost as much noise as signal. Surprisingly the signal didn't come out of the amplifier looking like that. The only thing I can conclude is that most of the noise is above the passband of the amplifier. However, the noisy signal is fed to channel 1 of the scope for phase readings. I don't think that readings could be very accurate with all of this noise. My solution is shown in figure 24 below.

Figure 24 Amplifier Test Setup.

The signal generator is set to 1 volt which is fed to channel 1 of the scope. After the 40 dB attenuator the signal is 10 millivolts which is what the amplifier needs. The only problem is that the gain of the amplifier comes out 40 dB lower than it actually is. I couldn't find a way to add an offset to the dB scale. I think this would be a very good addition to the software. Are you listening Digilant? The gain values given in the table below have been corrected by adding 40 dB to each one. You will note that although the simulation says the amplifier is stable at unity gain the measurements on the real amplifier make it clear that it is not. The gain is well above unity at zero phase on the high end.

Figure 25 Open Loop Gain of Breadboarded Amplifier.

Figure 26, Figure 19 Repeated for easy comparison. Open Loop Gain of Simulation.

Points of interest as picked from

above graph using the cursor.Analog Discovery Graphs Read

Using Expanded Scales.Point Name Frequency (Hz) Gain (dB) Phase (°) Frequency (Hz) Gain (dB) Phase (°) Lower Gain Margin 0.2882 -16.67 0.0 1.0 -41 0.0 Lower Phase Margin 0.9115 0.0 -47 16 -0.0 81 Lower Half Power 365.8 52.10 -134.9 1.1k 35.9 -135 Peak Gain 948.4 55.12 -179.7 3.0k -38.9 180 Upper Half Power 2.492 k 52.10 +134.7 7.8k 35.9 +135 Upper Phase Margin 1.610 Meg 0.0 +90.87 105k +14 0.0 Upper Gain Margin 48.98 Meg -33.90 0.0 430k 0.0 -127 Actually, before I ran any graphs I connected up feedback resistors to make a unity gain inverting amplifier. I was surprised and disappointed to find that it was oscillating at about 100 kHz. LTspice did pretty well with the DC operating points but not so well with the gain and high frequency response.

A measurement of gain done manually, that is the old fashioned way, came out as 38.8 dB. That's only 1/10 dB off from the results given by the Analog Discovery. But it's pretty far off from the simulated value of 55.1 dB. That's not enough gain. The graph in figure 21 shows a decided fall off at low frequencies as opposed to the op amp IC version shown in figure 17. (Note: Figure 17 can be found near the bottom of the incomplete equalizers article.)

What to Do?

A little experimenting has shown that increasing the current in the cascode stage will increase the gain. Cascode stage gain can also be increased by increasing the plate load. I also plan to remove all frequency compensation including changing C1 back to a 0.1 uf. After I get the gain that the circuit needs to function properly I will recompensate it to be stable at unity gain. Or maybe I can make use of that infrasonic peak by moving it into the low audio band and adjusting its amplitude to be just right.Tuesday, August 17, 2021.

I'll spare you the details of the struggles of the last 16 days. I spent many hours running the low frequency response of the real amplifier using the Analog Discovery Pro. A scan from 1 Hz to 1 kHz takes 6 minutes and 9 seconds. From 100 millihertz to 1 kHz takes approximately 45 minutes. From 10 millihertz to 1 kHz takes approximately 5 hours. Sixteen periods of each input frequency are required to obtain the data for display.I decided that I might not live long enough to compensate an AC coupled amplifier. The alternative is to make it more like an op amp with direct coupling throughout. That turned out to be easier than I had thought. Here is the schematic at the current state of development.

I have spared you the gruesome details of getting from figure 22 to figure 27. Suffice it to say, it was not a straight line because it involved so much trial and error. It wasn't nearly as easy as I had thought it would be.

Figure 27, DC Coupled Amplifier, Closer to True Op Amp.

Thursday, September 02, 2021.

Meanwhile there was something else going on starting on August 17 I was not yet aware of. I think I discovered what it was on the 24th which would have been a week later. I went to upload some updated files only to get the message that the file could not be transferred. I had run into this before when I had forgotten the Angelfire rule and included a space in the file name. I checked but there were no imbedded spaces. Next I tried deleting the file from the server only to get the message can't delete files. My next approach was to go to the Angelfire sight and upload the updated file with their web shell. That was also a no go and I soon noticed the red text that explained it all. It seems they started an update of their operating system and migration of user files to a different server on the 17th. They said it should take about 10 days. Since it had only been 7 days I shrugged and continued working. It has now been 16 days since they started and I still can't upload anything. At this point I don't know when you will be able to read this text and see the updated figures. But I'll carry on because it can't last forever. Can it?Some notes about the schematic. The breadboard looks much the same except for those two big ugly 1000 μF capacitors. As the schematic above shows the two resistors in the cathode of the cascode have been replaced by a single one and the cathode bypass capacitor is now a 100 μF 100 volt unit ordered while awaiting Angelfire to be reignited.

The 10 k ohm load resistor is shown on the left side of the schematic for my convenience when it comes to redrawing the schematic showing the application of feedback. The feedback resistor is a load on the output of the amplifier, any amplifier. Many student laboratory experiments meet with failure to correctly predict the gain because the loading of the feedback network is not taken into account. By placing the eventual feedback resistor as a load the amplifier has the same load in both open and closed loop modes.

The network consisting of the 330 kΩ resistor, 150 kΩ resistor, and the 100 kΩ pot, is both a level shifter and an attenuator. The level shifting is wanted, the attenuation is not. This was, and still is, common practice in tube op amp circuits because there is no PNP tube. Too bad. In this case the level shifting side effect became useful for the insertion of a lead/lag compensating network. This actually simplified the high frequency compensation of the amplifier although there were several false starts in this area before I arrived at this solution.

Figure 28, Open Loop Gain of DC Coupled Amplifier.

Remember to add 40 to the vertical scale of the top graph.

Friday, September 03, 2021.

My ability to upload files came back today. So it looks like Angelfire is finished with their update and migration. It does seem to be faster to connect to my FTP program. And now back to our story.Above is the open loop response of the real amplifier taken with the Analog Discovery. The plot shows stability because the gain is already below unity at 1 MHz while the phase is about 25 degrees as it approaches zero. Also where the gain is unity, 0 dB, the phase is about 50 degrees. It is hoped that this is not enough to sustain oscillation.

The gain can be seen falling off below 10 Hz. Remember that zero on the scale is 40 dB of gain. The gain does not fall to zero, -infinite dB, below 1 Hz as would be the case with a capacitor coupled amplifier. The fall off is due to the cathode bypass capacitors on the cascode amplifier. Here is the graph of open loop frequency response from 10 millihertz to 100 hertz.

Figure 28-A,Graph Showing Amplifier Response Below 1 Hz.

Actually the run time exceeded the earlier time of 5 hours. It was approximately 7 and a half hours. The Analog Discovery's default value for number of data points is always the same regardless of how many decades are covered. The result of my choosing to cover one less decade was to put more points in each one. That made all the decades take longer, especially the first two which ran up the run time.

-20 on the scale is 20 on the amplifier. So the amplifier's gain is 20 dB for DC and very low frequencies but rolls up to 58 dB before the audio range is encountered. The slope is less than the maximum permissible 20 dB per decade. The phase never gets close to 90 degrees.

You may be wondering why the 47 kΩ and 22 μF filter doesn't cause a low frequency roll off. The 47 kΩ carries the sum of the two 12AX7 plate currents. The sum of the cathode currents is regulated by a current sink. The current through the 47 kΩ never changes. Removing the capacitor would probably have no effect but it is left in place so the circuit will look normal.

Closing the loop.

Here are the results of testing the real amplifier in closed loop configuration. First the schematic.

Figure 29,Schematic of DC Coupled Amplifier with negative feedback.

Now in rapid succession are the frequency graphs for gains of 20 dB, 10 dB, 0 dB, -10 dB, and -20 dB.

Figure 30A,Gain of +20 dB.

Figure 30B,Gain of +10 dB.

Figure 30C,Gain of 0 dB (unity).

Figure 30D,Gain of -10 dB.

Figure 30E,Gain of -20 dB.

Tuesday, September 21, 2021. Adding the parametric circuit to the tube amplifier.

In the intervening time I have been playing with the circuit and trying to decide where to go next. This page has too much useless detail to just be added to the equalizers page. But I do need to wind it up. Here is the schematic of the entire circuit.

Figure 31,Schematic of Complete Parametric Equalizer.

And here is the simulation of the circuit.

Figure 32,LTspice Simulation of the circuit of Figure 31.

FIGURE 33, IT'S THE REAL THING.

Thursday, September 23, 2021.

One thing you might notice is that grid return resistors have been eliminated. Well, silicon op amps don't have return resistors on the inputs. The external circuit is supposed to provide that function. The two 10 k ohm resistors do the job for the inverting input. The 100 k ohm resistor is to make sure to discharge any coupling capacitors that may be connected there. The noninverting input always needs a return to circuit common. It is provided by the lower frequency pot in the Wein bridge circuit. The original silicon circuit had a DC blocking capacitor between the Wein bridge and the noninverting input. There was a 680 k ohm resistor to ground to keep the input where it belonged. There was another 680 k across the upper part of the bridge. I suspect that they were using a bipolar input op amp IC and the output level changed as the frequency control was turned. With tubes we have no such problem. Look back to figure 21. Note that the lowest frequency peaks are 2 dB below all the others. This is because the 1 Meg ohm grid resistor is in parallel with R23 which represents the rheostat connected frequency pot. There is no such resistor across R22 which is the upper frequency pot. The dual pot is at maximum resistance for the lowest frequency and the 1 meg ohm resistor is significant compared to the Maximum resistance of R23. Note that in figure 32, all the peaks have very nearly the same amplitude.Having a breadboarded version of the equalizer meant I could plug it into my stereo and listen to it. This is not possible with an LTspice simulation. I have been listening to The Brothers Four's Greatest Hits. The effect the equalizer has on normal music is not something you would want to listen to. But it is fun to play with.

Changing the Circuit For Different Applications.

Suppose you made a live recording and found when you got home that there was a peak or null at some obvious frequency. You could use this circuit to boost or cut that frequency. You can get a higher and more narrow peak by making the values of the two capacitors farther apart. This can only be carried so far before the circuit begins to oscillate.Say you wanted to use it to knock down a bass peak in your speakers. You could modify the Wein bridge circuit to cover a range of 10 to 100 Hz. This can be done by increasing the value of the resistors in series with the two pots. The frequency can be lowered by increasing the values of the two capacitors while keeping them in the same ratio to one another. Making the bottom capacitor smaller or the upper one larger will increase the height of the peak but if you carry this too far you will wind up with an oscillator. You could also use the same modification to increase the low bass below the normal range of your speakers but you could run into the power limits of your amplifier or if you have a power house of an amplifier you could damage your speakers, so be careful.

Friday, September 24, 2021. The frequency pot.

The resonant frequency of a Wein bridge is given by,f = 1/(2*π*R*sqrt(C1*C2))

Where both resistors have the same value. R is the value of the resistors and C1 is the top capacitor while C2 is the bottom capacitor. The frequency is proportional to 1/R. The 500 k ohm variable resistor (pot) in figure 31 gives a frequency of 68.1 Hz when set to maximum. Decreasing the pot's resistance increases the frequency. If a linear pot were to be used the first decade would be covered as the pot decreased from 500 k ohms to 50 k ohms. Assuming 300 degrees of pot rotation this would take place in 270 degrees and the rest of the frequency range in 30 degrees. What is needed here is a dual reverse audio taper pot. Some early TV sets used reverse audio taper for the contrast control but finding a dual one is probably impossible. For my breadboard circuit I wired a conventional audio taper pot backward which meant that the highest frequency was fully counter clockwise. If I were going to build this for daily use I would get some of those plastic gears used by kids to build robots and gear the frequency pot for reverse action so clockwise rotation would increase the frequency.

Conclusion.

If you have a recording studio with even a moderately priced mixer it has a parametric equalizer in every channel. If you have a very small recording setup you might find one channel of this circuit to be useful. Your need for it is likely to be altering the timbre of one voice or instrument so only one channel should be needed.If you want it for your stereo entertainment system you should build two channels. If that's what you want I won't second guess you. For myself I find that playing with the controls for a few minutes to be amusing but it's not something I would install in my system and switch in every day. But as that comedian used to say "different strokes for different folks". What was his name?

One More Thing.

After I transplant this page to the equalizers article it will include verbal descriptions of all figures. The graphs and diagrams that appear on this page are overkill. I do this to demonstrate how the design process works, dead ends and all.Case Closed.

HOME.

Protecting My Expensive Scope.

Saturday May 1, 2021.

In many areas I am an early adopter. One such is the Analog Discovery series of products. The latest one is the Analog Discovery Pro which has a list price of $1295. Because I had previously made a purchase from the website I received an email informing me of the introductory price of $295 off the list price. Hard to pass up something like that and I couldn't. I now have a 4 channel USB scope with built in function generator. The one catch is that its highest range is plus or minus 25 volts with protection to a maximum of plus or minus 50 volts. (5 volts/div with a grid of 5 div up and 5 div down from center.) Even when a times 10 probe is used this is marginal for use in tube circuits.There are situations where a direct (X1) probe must be used to achieve a usable signal to noise ratio for some measurements. OK, so I'll end every tube circuit with a series DC blocking capacitor and a shunt resistor. But there is still a problem. That is the instant when the B plus supply is turned on and off. The Fluke supply I use for powering tube circuits rises to 90% of set voltage in about 200 ms. (0.2 seconds). The fall time is even faster because the connection to the regulator output is opened by the standby switch. (Note: When the Fluke is put into standby the output voltage of the regulator is reduced to about 100 volts regardless of a higher setting.) Simulations have shown that for a coupling capacitor of 0.1 μF with a 1 Meg Ω resistor to ground, there is a high probability of damage and if a 1 μF cap is used it will be goodbye $1300.

My first thought was to install a switch in my breadboard that could be wired in to any circuit to short the output to ground after the capacitor. But that means that I would have to make sure the switch was set to the ground position before turning on the power and always set it to ground before turning the power off. It would only take one moment of forgetfulness, and goodbye scope. The short out has to happen automatically on turn on and turn off.

I looked through my junk closet and found a 10,000 ohm plate relay that reliably closes with 1 mA of current. It seems as though I might contrive a completely passive circuit that will close on power on and power off and stay closed for about 1 second.

For those who may want to try to find a duplicate relay here are the data on it. It is a Sigma brand as later pictures will reveal.

Here is the pinout diagram along with the color of wires I have soldered to each terminal.

Here is a picture of the relay next to the adapter plate |I made to mount it in an octal tube socket cutout.

The difficulty is that the relay has mounting studs in the corners as you can see. These are not the same spacing as the octal tube socket mounting holes. Even if they were the relay would be at a 45 degree angle which would take up more space in a place where space is at a premium. Things were further complicated by the fact that the dimensions of the relay can were exactly the same as the tube socket mounting hole spacing. This is the reason for using standoffs to mount the relay to the adapter and the adapter to the chassis.

The picture above shows the relay with the adapter installed and the two below show the assembly mounted to the breadboard chassis.

Monday, May 17, 2021. A circuit that works.

Here is the circuit that works. The extremely sensitive relay I happen to have, made it possible without any amplifying components. If you are not able to track down a similar relay let me know what you are able to find and I'll see if I can develop a circuit, probably with a transistor, that will work as well. If you would rather design your own, go right ahead.

CUT = circuit under test. PSU = power supply unit.

How It Works.

We will begin with the B+ turned off and the relay open connecting the output of the CUT (circuit under test) to the scope. All capacitors are fully discharged. When the B+ is turned on the voltage usually comes up within a few tens of milliseconds. For the first instant of time just after B+ comes up, the voltage across all capacitors is zero. The full B+ voltage is applied across the series combination of the 18 k ohm resistor and the relay coil. The 2.2 μF capacitor briefly shorts out the three 22 k ohm resistors. The voltage across the relay coil is limited to 15 volts by the zener diode protection network consisting of two anti seriesed diodes. But even so the relay gets quite a jolt and closes quickly. This disconnects the output of the CUT from the scope and connects the output to a 10 k ohm resistor to ground.Now all of the capacitors begin to charge. The shortest time constant is the 0.1 μF capacitor and the 10 k ohm resistor in series with the output resistance of the amplifier. Depending on the tube and circuit this could be as much as 80 k ohms. The charging current flows through the capacitor, the 10 k ohm resistor and the output resistance of the amplifier which are all in series. .Most of B+ will be dropped across the high output resistance of the amplifier. When the relay does open the voltage applied to the scope will be small. In cases where the output resistance is 10 k ohms or less the time constant will be so short that the 0.1 μF will have fully charged when the relay opens.

Meanwhile the 2.2 μF and 10 μF capacitors are also charging. The 2.2 is charging through the 18 k ohm resistor Which gives a longer time constant than the 0.1 cap and 20 k ohms. For a short time the 10 μF is charging through the 18 k ohm resistor but as the 2.2 cap charges the time constant becomes 10 μF times 84 k ohms. To calculate this on paper would require writing simultaneous differential equations which is not something I care to do. An easier way would be to simulate it with spice or test it on the breadboard.

After the 2.2 μF capacitor becomes mostly charged the only time constant left is the 10 μF and the 4 resistors, 3 22 k ohm and 1 18 k ohm, making 84 k ohms. By this time the zener diodes have begun to conduct taking the 10 k ohm relay coil out of the equation. As the capacitor charges exponentially the current falls. The relay drops out at about 0.55 mA disconnecting the 10 k ohm resistor and reconnecting the scope.

When B+ is turned off most Tube based power supplies become open circuits because the turn off means is to open a switch or relay. The only current path for discharging the capacitors would be the circuit itself. This may not be enough current to close the relay for a long enough time or even not at all. This is the reason for the 30 k ohm 25 watt resistor across the power supply. This must become part of the breadboard along with the relay and its associated components.

When the B+ is turned off the relay will close again and all the capacitors begin to discharge through the 30 k ohm resistor, the relay coil, and their own discharging resistors. The 0.1 μF capacitor is discharging through the 10 k ohm resistor in series with whatever resistance the CUT presents while being supplied with near zero voltage. By the time the relay opens the voltage applied to the scope input will be small.

The 2.2 μF capacitor will give the relay coil a little extra jolt to quickly close the contacts. It will discharge leaving the matter up to the 10 μF capacitor.

The 10 μF will discharge through the 30 k ohm, a total of 84 k ohms and near the end the relay coil. By the time the relay drops out the world is safe for oscilloscopes to remain connected.

Component Selection.

If you didn't wade through the paragraphs above I will make the point again here. The 30 k ohm high wattage resistor must be part of the breadboard along with the relay and its associated components. It is required to make the relay operate on B+ turn off. Use V2/R to calculate the wattage for your power supply. Also the maximum of your supply will determine the voltage rating of the 10 and 2.2 μF capacitors.I have already discussed the relay. The 2.2 μF capacitor is a 630 volt standard poly plastic type available from Antique Electronic Supply and others. The 10 could be made up of 4 2.2 and 1 1.5 μF in parallel. In my case it is a motor run capacitor I acquired from either BG Micro or MPJA, I don't remember which. If you buy regularly from either of these suppliers you know that their email offers aren't around for very long. Truth to tell there is no reason for specifying a nonpolar cap. The voltage across the capacitor never reverses. I think that leakage is likely to become a problem with an electrolytic. Their leakage grows as they age. This would cause the relay's hold in time to be longer on turn on and shorter on turn off. Also the maximum voltage of your power supply may play into your selection. My Fluke goes up to 550 volts and my HP 712B to 500 volts. If your only supply is a Heath IP27 or the Eico equivalent then 450 volt capacitors would serve. Also the 30 k ohm 25 watt could be down sized to a 10 watt.

Ground and B-.

B- and B+ are the negative and positive ends of the voltage source that is your bench power supply, or power supply unit. When you connect it up to power a circuit on your breadboard B- is connected directly to circuit common, (ground), most of the time. But there may be times when you need to separate B- from common ground. I have such a case on my breadboard at the moment. I have designed, in LT Spice a high gain AC coupled amplifier with differential inputs similar to an op amp. For this I need -105, +105, and +255 volt sources. As I'm sure you have already guessed I have a string of 3 VR tubes, two 0C3s and a 0d3. Like any bench power supply worthy of the name it is completely floating and doesn't care if it is connected as negative ground, positive ground, or neither side at ground. My case is the latter. The relay circuit needs to sense what the power supply is doing which means that it must be connected from B- to B+. Like the power supply, the relay coil circuit is completely isolated from ground.The contact circuit is another story. The 1 meg ohm and 10 k ohm resistors must be connected to the common ground of the CUT. On my solder breadboard ground is the metal chassis that the breadboard is built on. The triangular ground symbol is circuit common in modern electronics but in this case it is also chassis ground. Here is how to use the protection circuit with an amplifier circuit.

Schematic showing an oversimplified amplifier being used with the scope protection circuit.

Thursday, June 03, 2021.

Earlier I wrote, "…the relay gets quite a jolt and closes quickly." Not quickly enough as it turned out. I simply forgot that a relay takes a finite amount of time to close. Here is the proof.

Scope screenshot showing turn on traces..

Scope screenshot showing turn off traces..

Just for the record the yellow trace is the instantaneous power supply output voltage and the purple one is the voltage from the CUT output. The turn on transient would be bad enough with a peak of 60 volts with a little narrow spike to about 75 volts but the turn off transient is a roughly flat topped pulse of about -100 volts. Nice try but this one has to go in the failure column.

The second plan.

The next version must have two relays. One to turn high voltage on and off and the other to disconnect the scope input. The sequence of events must be this.Turn on cycle. HV switch at the power supply end will remain on at all times.

- Relay A closes disconnecting scope and connecting a 10 k ohm resistor from CUT to ground.

- Delay greater than relay closure time.

- Relay B closes applying HV to CUT.

- Delay of 2 seconds, possibly adjustable.

- Relay A opens connecting output of CUT to scope.

HV remains on.

- Relay A closes disconnecting scope and connecting a 10 k ohm resistor from CUT to ground.

- Delay greater than relay closure time.

- Relay B opens removing HV from the CUT and connecting a 30 k ohm resistor across its HV terminals.

- Delay of 2 seconds, possibly adjustable.

- Relay A opens ready for next turn on cycle.

I was thinking that the only way to control these two relays would be with an Arduino. But now that I write down the steps I see the similarities between turn on and turn off. I did find another one of those Sigma plate relays but I'm not sure how robust the contacts might be. In any case I'm not going to try to mount anything in the breadboard chassis. I'm going to use an external control box that can be used with any breadboard.

I realize that leaving the HV turned on is a safety consideration. This can be somewhat mitigated by hard wiring the leads into the control box to prevent the hot ends from being unplugged in a moment of forgetfulness.

Saturday, June 19, 2021. A circuit design.

I did a lot of head scratching and came up with the following circuit.

I was getting ready to breadboard the circuit and arrive at the capacitor values when the KISS* center in by brain woke up and asked "what the hell do you think you are doing?" I quickly designed the circuit below. As with any circuit I am going to breadboard it but it seems almost foolproof.

* KISS = Keep It Simple, Stupid.

I chose the series resistor to give an upper frequency cutoff of just over 400 kHz with a 100 pf capacitive load. If a particular circumstance requires, it can always be changed.

Sunday, July 11, 2021. Case not closed.

Construction.

There is a set of circuit boards that can be found on the web in many places. Instead of the connected pads that duplicate the breadboarding socket, which I have used many times, they have individual unconnected pads that are double sided and plated through. As such they are considerably more robust than the earlier boards. Their disadvantage is that the user must supply all point to point wiring. Their advantage is that the user can supply all point to point wiring.As I have done before I made a representative drawing in MaxCAD of the board without components or wiring. The drawing is locked so none of the elements can be deleted. The file is also write protected to keep me from saving a component layout drawing over the blank board file.

Then I added the parts, diodes and resistors. In my set of shapes for diodes I made no distinction between PN diodes and Zener diodes. I should look into fixing that oversight.

The next step is wiring the board. I didn't see the letter designation of columns and numbers for rows until I placed the board under my digital microscope for soldering. Next time I'll put the board in the proper orientation so the letters and numbers will be right.

Final step is testing. The other three look exactly the same.

The only thing that could burn out some diodes would be a short in one of the large yellow capacitors. While that is within the realm of possibilities I have enough spare diodes and zeners to make replacements.

Wednesday, July 14, 2021. Lett's call it an overvoltage protector.

In the picture below you see the afore mentioned large yellow capacitors. I have decided to install the protection circuit on the breadboard I use most often.

Now For the Scope Test.

I might not have made myself clear. The scope I am protecting is the Analog Discovery Pro which has a rather frail maximum input voltage rating of +/- 25 volts. This is a USB scope although you would never know it from the price. The scope I used to make the test shown below is a standard bench top scope. The maximum input rating is 300 volts without the probes. When probes are used the maximum voltage is not 3000 volts but is the max rating of the probes. This is usually printed on the probe. In this case 600 volts. I am safe in making this experiment.Here is the turn on,

and here is the turn off.

It now appears that as long as I wire my output through this test circuit the world is safe for USB scopes.

Case Closed.

HOME.

Adventures With a Network Analyzer.

Wednesday, September 16, 2020.

Several years ago when a company called "Syscomp Electronics Design Ltd." Came out with their CGR101 I couldn't wait to order one. It wasn't and isn't just another software oscilloscope. It was and is capable of plotting frequency response and displaying amplitude on a log-log graph and phase information on a log-lin graph. In other words a network analyzer, also known as a Bode, pronounced "Bodey" plotter. My first major use of it was to make and post impedance plots of speakers. The file dates are in late march of 2014. Good grief, was it that long ago?

I don't remember when they came out with a new and improved version the CGR201. I bought one and when it came in I gave it a brief test and put it away for the next time I would need it.

The need arose when I wanted to plot the frequency response of the real version of the Tone control circuits I had been simulating with LTspice. I got it out, connected everything up and ran a couple of plots. Then I started getting an error message. I don't remember the message exactly but it was something to the effect "…can't read START_FREQ no such location.". This sounds to me like a variable name in a program. So I downloaded the software again and installed it over the original version. While doing all of this the device was disconnected from the computer. After a little finagling to get the program to look on the right port to find the device it worked. I started plotting the tone control circuit I had wired on the breadboard. After a few plots I started getting the same error message. By this time it was late so I went to bed to sleep on it.

I tried reinstalling the program again but this time I uninstalled the old version and deleted the directory which the uninstall program had left behind. It worked at first but started giving the error message again. I set it aside and moved on to another project. When I came back to it a few days later I tried it several more times from a cold start. On every try it worked for about 20 minutes and then gave the message. Then I began to think in terms of assembly language programming and a name given to a memory location. I must have a hardware problem. I didn't test it for a long time so it may have been defective out of the box but I was sure it was much too late for any repairs covered by the warranty. I went back to the website to buy a new unit. After all, it's only money. But it was out of stock. I found that everything listed on the site was out of stock. I suppose the company has folded. Oh well, it happens.

I never throw anything away.

You've already seen the picture of the original device so you know I still have it. It came with an installation CD in the bottom of the plastic box. Insertion of the CD resulted in an error message, what else is new, "this program cannot be installed on this version of windows". I'm not one who gives up easily. I ran the install program as administrator and it ran and installed. The program balked but I ran it with troubleshoot program compatibility and selected Windows XP as the program it last ran under. If you ever need to do this the last step is easily missed because you are not directly prompted for it. Before closing the troubleshooting window be sure to check the box "Remember these settings". I checked it and now the old program runs just fine with the old hardware. For those who may be wondering the old program would not recognize the new hardware and vice versa. So now I can add a little more to the tone controls page in which I compare LTspice simulations with results from a breadboarded circuit.Case Closed.

Friday, October 23, 2020.

Case Reopened.

While searching the Circuit Specialists site for an alternative to the Syscomp I found the Analog Discovery 2 from Digilent.com. It was listed as out of stock but it looked so interesting that I ordered it and settled down for a long wait. Early in October C S informed me that the price had gone up and asked if I wanted to cancel the order. I said no and it eventually came in. I downloaded the software and set about getting it to work.I installed the software, plugged in the device and started the program. It is my normal MO to start a program and try to figure it out. My reason is that help files are generally useless because when you do a search for something they tell you about everything else instead of just answering the question you have asked. I have found that after I have an idea of how to do the basic things the help files are comprehensible and I can then take in the subtleties Here is what I saw.

This is the welcome screen. At first I wasn't sure the program and the device were talking to one another. I eventually determined that they were. After the fact I noticed in the lower right corner a box containing "Discovery 2" followed by the serial number. This is how you know it's working.

The Analog Discovery 2 comes with a 30 pin socket which fits onto a mating plug on one side of the device. The 30 wires that come out of the socket have female connectors, one on each wire. These will fit the pins on Arduino compatible devices but a number 22 gauge solid wire will fit nicely. I decided to connect the outputs of the on board signal generator to the inputs of the scope. I did this using one of the 5E boards which I had purchased when they were discussed on the list some time ago.

Saturday, October 24, 2020.

I selected "Waveform" from the menu on the left and this screen came up.

This picture is not of the first screen I saw. The information for only one channel was displayed and it filled the window. The green triangle followed by the words "Run All" was encouraging. Green is always good, right? Just to the right of this is another button labeled "Channels". Clicking it causes a drop down menu to appear which will show channel 1 checked and channel 2 not checked. Clicking on "Channel 2" will check it but the menu doesn't get out of your way. I know from my own experience in programming that this is an oversight by the programmer. After a user selects an option from the menu the programmer has to include a line of code that will tell the menu to "get off the screen". To overcome the forgetfulness of the programmer you must click the mouse in any area of the screen that is not a button, dialog box, or drop down list. After checking both channels you need to set them to be synchronized. To finish setting up the generator you should move again to the right where a drop down list will be showing "No Synchronization". Click on this and change it to "Synchronized". Note: Somehow the word "Disabled" inside the red boxes escaped my notice. Well, I do have a valid excuse.

To bring back the welcome menu click on the word "Welcome" almost in the top left corner of the window.

Sunday, October 25, 2020.

Next I clicked on "Oscilloscope" in the welcome menu and this screen came up.

The o'scope settings are on the right. The screen came up with both channels set to 1 V/div but I changed them both to 500 mV/div to get a larger display from a 2 volt peak to peak signal. But as you can see there was nothing. Not even an undeflected trace line. What could be wrong?

The signal generator and scope are two parts of the same system. I decided that testing them separately would be a good idea. I fired up my bench scope and connected its probes to the outputs of the Discovery's signal generator while leaving the Discovery's scope connected. There was nothing. I went back to look at the settings of the generator and everything looked right. Frustrated, I decided to leave it alone for a while and cool off. I can't think straight when I'm P O-ed. I make mistakes that compound on each other and make things worse.

Prior experience with software has taught me that an orderly shutdown is always best particularly if things aren't going well. So I clicked on the green arrow which changed to a red dot. The red frame just below the buttons changed to green and the word "Trig'd" appeared inside it. AND, the two sine waves appeared on the screen with a 90 degree phase difference as I had set it up. Not only that but the same two waves appeared on the screen of my benchtop scope. Well, it appears that green does not always indicate that things are running. Except for the rectangle in the top left corner of the scope screen.

Monday, October 26, 2020.

I am accustomed to using music players in which the triangle is used to indicate play and the double vertical bar for pause. The button shows what you will get if you press it. By this rule if you press the button when the green triangle is showing you will go into the play mode which some might interpret as showing the wave on the scope. Then after you press it a red dot indicates you will go into record mode if you press it. I'll leave it to the reader to decide what record mode for an oscilloscope might be. Pressing the round red button takes you back to the green triangle but the displayed wave remains on the screen.OK, I'm being nit picking. The button does say "Run" and that's what you get when you click it. When it is running the button says "Stop" and that's what happens when you press it.

Testing the Network Analyzer.

The next thing I did was to wire up a simple RC low pass filter with a 0.1 uf capacitor and a 1500 ohm resistor.

And here is the circuit wired on a 5E board.

With everything connected up I clicked the green triangle and here's what I saw.

The phase shift should be 45 degrees and the amplitude 0.707 volts peak. I leave it to the reader to verify this. Without any rewiring it should be possible to do the network analysis (make a bode plot) of the circuit. Click "welcome" then "Network".

The gray area on the left is the cursor. I pressed print screen just after it arrived there. This program keeps scanning as long as you leave it running.

We see that the phase shift is 45 degrees at 1 kHz as it should be. The amplitude should be -3 db. That's pretty hard to read on a 10 dB/div scale. If I were still using the Syscomp that would be the end of it but with this software the user can change the scales of the graph as seen below.

With a scale of 1 dB/div it is clear that the amplitude is -3 dB at 1 kHz as it should be. And as I continue to learn the program I found that when the stop button is pressed the traces do not disappear but the cursor does. Also if the scale is changed to look at a small part of the graph as was done here there is no need to do a rescan.

Wednesday, October 28, 2020.

The learning continues. Scroll back up to the photograph showing the resistor and capacitor on the 5E board. That's the one just below the schematic diagram. Now scroll down to the scope display of the two sine waves just below the photo. Look not at the "oscilloscope screen" but at the row of 5 tabs just below the menu bar. The "Welcome" and "Help" tabs are there at program startup and are always present. Tabs are added as you make selections from the "Welcome" menu. On this occasion the first thing I did after starting the program was to accidentally click on the "Supplies" button. That placed the power supplies tab in the tab bar and I didn't yet know enough to remove it. To remove an unwanted tab just click on the X to the right of the word. The next thing I did that day was to set up the wave generator so that tab appears next. Then I looked at the waves on the oscilloscope which is the next tab. Scroll down again to the network analyzer screen. The next thing I did was to go back to the "Welcome" menu and select "Network" the network analyzer. In the graphic you can see that the "Network" tab has been added to the tabs bar. In the next graphic down with the expanded vertical scale the tab bar has changed. That is because I closed and later restarted the program between taking those two screen shots. I would have run the network analyzer with the default scale of -90 to +10 dB and then adjusted the scale to -9 to +1. Remember these graphics are screen shots taken while the program was running not the program itself. Clicking your mouse on buttons will have no effect or one you didn't expect.Clicking on the word in a tab will allow you to edit or view that function. Clicking on the green triangle will set it to run mode, clicking on a red dot will stop it from running. Clicking on the X will remove the tab from the tab bar.

Now Let's Look at Something Useful.

How about a 3 band active tone control. Here is one built on a solder breadboard. The BNC adapter had been ordered but not come in when I made these plots.

And here is its frequency response as revealed by the Analog Discovery.

That seems to be about all I have for the moment. I've got a lot more to learn but there seems to be no escaping the PDF manual. There are still some unexplored items in the welcome menu. So I won't give you a case closed or a to be continued.

Conditionally To be continued.

HOME.

Winding I F coils.

Previously on Adventures in Coil Winding…

Our intrepid hero was given part of a Morris coil winder by Bill and bought another one on eBay to emulate Bill's setup. Then he felt overwhelmed by the complexity of the whole process and had doubts about going on with the project. After some consideration he found new confidence and decided to forge ahead. He assembled his coil winder powered by stepper motors and successfully wound a total of 12 coils. He also tested several solder fluxes and several methods of coil doping. Details can be seen at the page on winding IF transformers.Wednesday, December 12, 2018. Making transformers from the coils.

I had ordered some polycarbonate rod from McMaster Car to support the coils. I thought I could make the square end pieces from sheet plastic I had on hand. It was only 0.09 inches thick so my plan was to glue two pieces of it together. In the past someone had recommended the use of silicon rubber to glue Plexiglas together but I found that the bond was not very strong. Crystal Clear Gorilla glue makes a strong bond but the pieces move on each other and it's hard to keep them lined up while placing a heavy object on top to clamp them together. It's best to glue first and cut and drill after. I found some 1/4 inch sheets at Home Depot which solved the glue up problem. Here is what they look like.

The 4 copper wires are for electrical connection and add no significant structural strength to the assembly. The polycarbonate rod is made slightly oversized and is a very snug fit in a 1/4 inch hole. The square end pieces had to be tapped onto the ends of the rod with a small hammer.

These transformers will use the same tin plated steel cans made by J. Ed. Earlier these were found to reduce the Q of coils inserted into them.

Table X, Q of coils as effected by Shield Can. Coil # Q Shield 10 88 None 12 86 None 10 58.5 Tin Plated

Steel12 58.2 Tin Plated

Steel10 64 TPS Can Lined with

Copper Foil Tape12 63 TPS Can Lined with

Copper Foil Tape

The transformers behave quite differently when in or out of the shield cans. That means that the coupling (distance between coils) must be adjusted in small increments and the transformer reinserted into the shield for the measurement. Also the can must be grounded to the system ground. We can take measurements from the scope screen shots below and learn something about the transformers.

Input impedance = VCH2 R / (VIN - VCH2 ZIN = 1.56 x 470 k ohms / (10 - 1.56) = 86.7 k ohms.

Insertion loss = 20 LOG (VCH2 / VCH1)

Measured at the same frequency.Loss = 20 LOG(1.61 / 1.42) = 1.1 dB.

Because the output is slightly higher than the input the second transformer has insertion gain rather than insertion loss. Because of this it took two pictures to show everything.

Making the same calculations for transformer 2 as for 1 gives.

ZIN = 1.65 x 470 k ohms / (10 - 1.65) = 92.6 k ohms. Gain = 20 LOG(1.74 / 1.65) = 0.5 dB.

I'm beginning to think that this coil winding business is more of a black art than a science. In the case of transformer 1 the slight asymmetry of the secondary voltage curve indicates over coupling. But if I pushed the coils any farther apart the loss factor began to climb. Perhaps I should have tried to achieve equal bandwidth in the two and losses be damned. But I didn't and the bobbins on which the coils are wound are glued to the polycarbonate rod with Crystal Clear Gorilla Glue. In the early part of the drying phase it behaves somewhat like rubber cement including the ability to roll off glue that is where you don't want it. But when it is fully dry it is much stronger than any rubber cement ever imagined. It might be called super industrial strength rubber cement.

I am returning Ed's transformers to him but all he will get back will be the original TPS cans and the trimmer capacitors. I have replaced his original wooden structure with plastic and the coils with ones wound with litz wire in a standard winding. This has added considerable value so I don't expect Ed to complain.

My next step is to try making the tin cans myself. I have all the necessary tools but the precision cutting required is likely to test my ability to cut a straight line on my band saw.

Stay Tuned.

HOME.

Musings upon building a tube analyzer.

Monday, January 15, 2018.

For some time I have been contemplating building some kind of tube tester, curve tracer, or analyzer. Over the years I have received a few emails asking if I have a design for a valve or tube tester. As the usage indicates some of these have come from Europe. The main problem with tubes is getting all of those pins connected to the correct voltage source.It's easy with transistors which have only 3 leads. There are even devices you can get that don't care which leads go into which socket holes. It will figure out what kind of device you have connected and which socket connections go to which elements of the device. It's not nearly so easy with tubes.

A given tube may have anywhere from 7 to 10 connections.

Note. I get 10 connections from a 9 pin tube with a top cap. I have removed from consideration the 12 pin compactron and the very old 4, 5, and 6 pin tubes. I may include the old 7 pin socket for testing 807 tubes. I may also make adapters for these somewhat rare species.The most difficult part of a home brew tube tester is how to set it up for each tube type. The service shop tube tester, which I have one of, used a chart in the form of a scroll which listed all known tubes and gave the settings of a number of controls on the tester. The user has no idea of what is being set, I include myself in that. He just sets each knob to the position indicated on the chart pushes the test button and reads good or bad on the meter. These switches have many wafers and the wiring is quite complicated. Duplicating this method is not practical for the home brewer.

After a lot of thought I have concluded that a system of relays driven by a small microprocessor is the only way to go. Let's make a list and see how many connections we need to make.

Sources.

Note: Some tubes have a pin that is indicated as "internal connection, do not use". This pin must be left open.

- Filament or heater supply.

- Ground. For cathode and suppressor grid.

- Control grid bias.

- Screen grid supply.

- Plate supply.

- Open circuit.

The most obvious way of making these connections is shown below.

Figure 1 Easy Circuit.

This circuit is simple to understand and simple to build. It would also be simple to program but for the number of outputs from the Arduino, 50, that are needed to control the relays for 9 pins and a top cap.

Figure 2 Another Circuit.

Another circuit looked like a saving of one relay per tube connection until I realized that it needed one more relay to provide the necessary open circuit. Also double throw relays are usually more expensive than single throw.

Figure 1 is the one to go with. For controlling the relays I intend to use one of those binary to 1 of 10 decoders or maybe 1 of 16 depending on what's available now. I have on hand a few Nixie display drivers that should do the job. This will only require 3 active bits. The 23 bit can be tied permanently low. Alright, 3 bits times 10 tube connections, Hmmm. Still too many bits. Well, let's use another Nixie driver to address the tube connections. That's 4 bits. Now we are getting somewhere. 4 bits to address the tube pin and 3 to tell it what to connect to. 7 bits is no problem. Each set of relay drivers will need its own 4 bit latch but I have them also.

If you are thinking that I must have been buying for a frequency counter at one time you are right. The ICs were a small part of the cost. Before I got started making the PC boards a Heathkit came out that cost less than I would have put into an enclosure, displays, board making material, etc.

Here is my idea for a programming panel.

Figure 3 Tube Connection Setup Panel.

The double circles are the symbols for the push button switches and the circles with lines radiating out from them symbolize indicator LEDs. The power up default will be for all pins to be open. A push of a button will set a particular pin to the intersecting source. The switch array will be scanned. The drivers will be through another Nixie driver which will use 4 bits. The state sense will use up 6 bits for a total of 17 bits. Oops. Looks like I need to rethink something. Let's see. The top row is the open state which will be binary 000. If I connect the set of open switches directly to the clear input of the latch for that tube pin without going through the processor that will reduce the number of sense inputs to 5 which now makes 16 bits for connection programming. Scanning and sensing the switch array in software should be a piece of cake.

Now that we have the tube properly connected what are we going to do with it? Every entry in a tube manual has a "Typical Operation" section where the operating point is completely specified. Plate voltage, plate current, and control grid voltage. In the same table are listed the plate resistance and amplification factor or transconductance whichever is applicable to the tube type. I would like an analog test in which the plate and screen voltage could be independently set and the control grid bias also set. Then the plate current would be read out on a meter, either digital or analog.

Then pressing another button would cause the plate resistance, amplification factor, and transconductance to be calculated based on measurements and read out on a single or multiple meters. Some processor time would be a great help with the measurement control and calculations. Since the 16 binary connections on the Arduino can work in either direction a 16 bit CMOS analog switch would need to be used to change between setup and measurement mode. The problem is how to tell the Arduino to run a different program based on the setting of a front panel switch. Perhaps the interrupt input can be used for that.

The ultimate addition would be to add scope outputs to the tester and curve tracing software. Modern DSOs have a way to dump the screen to a thumb drive. The screen image could then be transferred to a PC and a graphics program used to draw load lines on the curves. Or if you want to be a little more retro the image could be printed out and the load line be drawn with a pencil and straight edge.

The one remaining problem to be solved is the power supply for all of this. The low voltage for the Arduino and external logic is no problem. It's the plate supply that will deliver enough current to test a KT99, 6550, or 6146 that is going to add a lot of weight and volume to the tester. A connection for an external power supply would seem to be the answer. This is in direct conflict with the ease of use rule. "The harder something is to use the less often it will be used." That calls for a built in power supply. Then we run into another ease of use rule for a piece of test gear that is stored on a shelf and must be moved to the bench for use. "The heavier and larger it is the les often it will be moved for use." Perhaps a compromise is in order. Enough built in power supply for testing small receiving tubes but external power connections for testing audio output and some transmitting tubes. This is something I will have to weigh before starting the construction process.

If anyone has opinions on this feel free to start a thread on the FWT list. It's easy for one person working alone to miss something. Any input you may have would be appreciated.

To Be Continued.

HOME.

Spectrum Analyzer Impedance Buffer.

Monday, July 17, 2017.

Looks like it's been almost another month. I suspect you know how it is. You get to working on a project and it is so much fun that you don't want to stop and document it. Well, it happens. The power meter is finished and now lives on a page of its own. It also lives on my equipment shelf where it looks good. Even Sue likes its appearance. This permits my return to the blind fisherman's buoy. To make some tests on that project I need to use the spectrum analyzer but the input impedance is too low to do what I need. And so it goes.That's right, I now own an RF spectrum analyzer. In February I decided to spring for it. Not a Keysite, not an Agilent, not even an old HP, but a Siglent. Probably made in China but isn't everything these days? It goes up to 2 GHz although I would have been quite happy with 200 MHz. It isn't useful for audio work because it only goes down to 9 kHz and the tracking generator is specified to go down to 100 kHz although it is usable down to 50 kHz. That makes it worthwhile having for receiver IF and RF stages and filter work. Its main limitation is that the input impedance is 50 ohms. Well I hear the manufacturer saying, it is intended for RF work. True. But when I need to sweep out an IF filter at 80 kHz a 50 ohm input impedance is a little low.

My mission then is to design and build a buffer amplifier that will have an input impedance equivalent to that of an oscilloscope so I can use a standard 10 meg ohm probe with it and a bandwidth wide enough to match my needs. Also I want it to be very compact and battery powered, no tubes, sorry.

I don't expect there will be huge demand for this circuit because there might be one other person on the FWT list who owns a spectrum analyzer. When I finally come up with a circuit you can duplicate I'll leave it up for a while. BTW, if anyone knows of a good spectrum analyzer that does audio frequencies please let me know.

Bandwidth?

When I started out I had no idea just how much bandwidth I could get with transistors on hand. I had to decide what would be the absolute minimum I could live with and the answer came back 30 MHz. What would I really like? 100 MHz came to mind. Anything above 100 would be chocolate sauce on the ice cream.I started digging through my store of transistors and found a couple of dual FETs and a few BJTs all with Heath part numbers. They must be replacement parts for a Heathkit oscilloscope. As such they probably have some pretty respectable Ft values. So I thought up a circuit using one of the FETs and one BJT. It looked like I could get 30 MHz out of it but it wasn't all that far down at 100 so I decided to try for it. Here is the original circuit.

I tried adding series RCs to the emitter with smaller capacitors but couldn't get the curve right. Guess I need to sleep on it as it is getting late.

Tuesday, July 18, 2017.

I must admit that I was not using the best techniques for broadband work. The tracking generator in the analyzer has a 50 ohm output but I didn't have it terminated. In fact I was using cables with clip leads on the ends for both input and output.Also, these socket breadboards are not the best for RF work. I do have a version I built that incorporates some features that should make it a little better. When I mounted the socket I put a piece of Plexiglas under it to cut down capacitance to the chassis. It has BNC connectors on the left and right and a lid that can be closed. There is no power supply which means that power must be introduced from the outside or in this case included inside, a 9 volt battery that sits inside with the circuit board. Eventually you will see a picture of it farther down this page. There is an older one WAY on down. It is just after the heading "Thursday, December 01, 2016"

I snapped a 50 ohm through termination on the left hand BNC and ran the shortest possible cable from the TG output to the breadboard input. Since the amplifier has a 51 ohm resistor in its output I just ran a cable from the right hand connector to the analyzer's input. Of course. Signals go in on the left and come out on the right. Right?

That was a much greater improvement than I had expected. Next I investigated the effect of changing the value of the source resistor in the FET source follower. A large value, 10 k ohms, gave more gain while a smaller value, 2.2 k ohms gave lower gain but better high frequency response. This is what I would expect. The wide dynamic range of the analyzer means that high frequencies are more important than gain.

Oscilloscope vertical amplifiers that I have seen schematics of show emitter followers between every stage no doubt to isolate the miller capacitance. I think I'll add an emitter follower between the source follower and the BJT common emitter stage.

Monday, August 14, 2017.

The blind fisherman's buoy is as good as I can get it with parts from China. Any improvement will require a considerable outlay of cash. I will have to consult the end user about that. Meanwhile I can get back to the impedance buffer for the spectrum analyzer.

I eventually came up with this circuit. It gives a really good looking sweep from 0 to 100 MHz as shown below.

To be continued.

HOME.

Modifying the HP334A RF Detector Circuit.

Tuesday, January 17, 2017.

Getting at the RF detector board turned out to be easier than I thought it would be. I did have to remove the main shield in order to get at it. It wasn't hard. Then there was a small shield around the board which was held to the rear panel by two screws and to another part of the internal shielding by two more screws. The circuit board was held to the rear panel by two screws. Just to make things interesting the HP designers had routed the output wire from the detector board through a hole in the detector board shield and the cable did not have removable connectors. The input cable did. So I had to work with the board and shield still connected to the main unit. It was difficult but not impossible.

Below is the unmodified detector circuit in figure 1 and the modifications drawn in by hand in figure 2.

Figure 1 Unmodified RF Detector in the HP 334A.

Figure 2 Modified RF Detector.

I replaced the diode on the board and also the spare which was held to the outside of the RF shield by two farnstock clips. I tacked on a 5.6 k ohm resistor to inject bias and reinstalled the board and shield. The resistor lead exited the shield through an extra hole which may have been put there for the purpose of biasing the diode. If so the hole would have been left in because there would have been a cost associated with removing it which over the production run would have been greater than the cost of leaving it in. At least that's my speculation. I used a shield mounting hole and screw to fasten a terminal strip to hold the two resistors and capacitor for biasing the diode and filtering the bias voltage to avoid adding noise from the power supply to the signal under test. See figure 8 under the heading "Low Distortion AM Detectors" below. I stole a bit of -24 volts from a nearby edge connector and I was ready to trial and error the resistor values. First I connected a substitution box between the power supply connection and the resistor lead coming out from the detector shield. I found a value that gave a minimum distortion reading at 100% modulation of my test generator and put a resistor of approximately 2/3 of the value to the detector and the filter cap that goes to ground. Then I tried the sub box between the negative lead of the capacitor and the negative power supply connection. This value came out larger than I had planned on for good filtering so I increased the value of the resistor going to the detector and found a new value for the other resistor. After several iterations of this procedure I found the following values. For the vertical resistor in figure 8 36 k ohms and for the horizontal resistor that connects to the voltage source 18 k ohms.

I put the whole thing back together and made some measurements. I was initially disappointed with the results. It was late and I was very tired and I probably read the wrong scale. Upon testing today I find satisfactory readings. I have flipped the axes of the chart so I can test at several different frequencies.

Signal source, SiglentDSG810.

Modified HP334A RF Detector. Frequency (MHz) THD (%) @ 90% Mod THD (%) @ 60% Mod 0.54 0.147 0.098 0.8 0.165 0.122 1.2 0.182 0.140 1.6 0.190 0.150 2.0 0.197 0.161 3.9 0.242 0.218 7.2 0.274 0.234 14.3* 0.340 0.249 21.3* 0.430 0.257 * Using a Siglent SDG1025 which may have more distortion. Wednesday, January 18, 2017.

There are no readings for 30% modulation because the meter was reading carrier leak through and noise.Thursday, January 19, 2017.