Ahhhh...the start of something big!!

The X Axis....This is where it all starts.

I began the construction with several trips to the Home Depot and Canadian Tire. In order to build the X Axis, you have to start with a base. I used 3/4" MDF for the base and painted it with several coats of Light Gray Tremclad paint. A word of advice if you follow suit....prime the edges of MDF with watered down white glue. Otherwise the MDF will suck up the paint faster than you can apply it.

Once the paint was dry on the base, the black gas pipes were assembled and aligned. Black gas pipe is used rather than galvanized as it apparently has tighter tolerances. The alignment process went fairly well, although it was a fussy job. I did have trouble at the Home Depot getting the less than expert staff to cut the pipes reasonably accurately. I would get them to cut a couple of spares if I were doing it again so you can pick the best ones of the group (that advise would have saved me two trips, and double cuts).

After aligning the pipes, they were filed, then sanded to remove the die marks from cutting/tapping. Then two thin coats of black gloss tremclad was used to seal them.

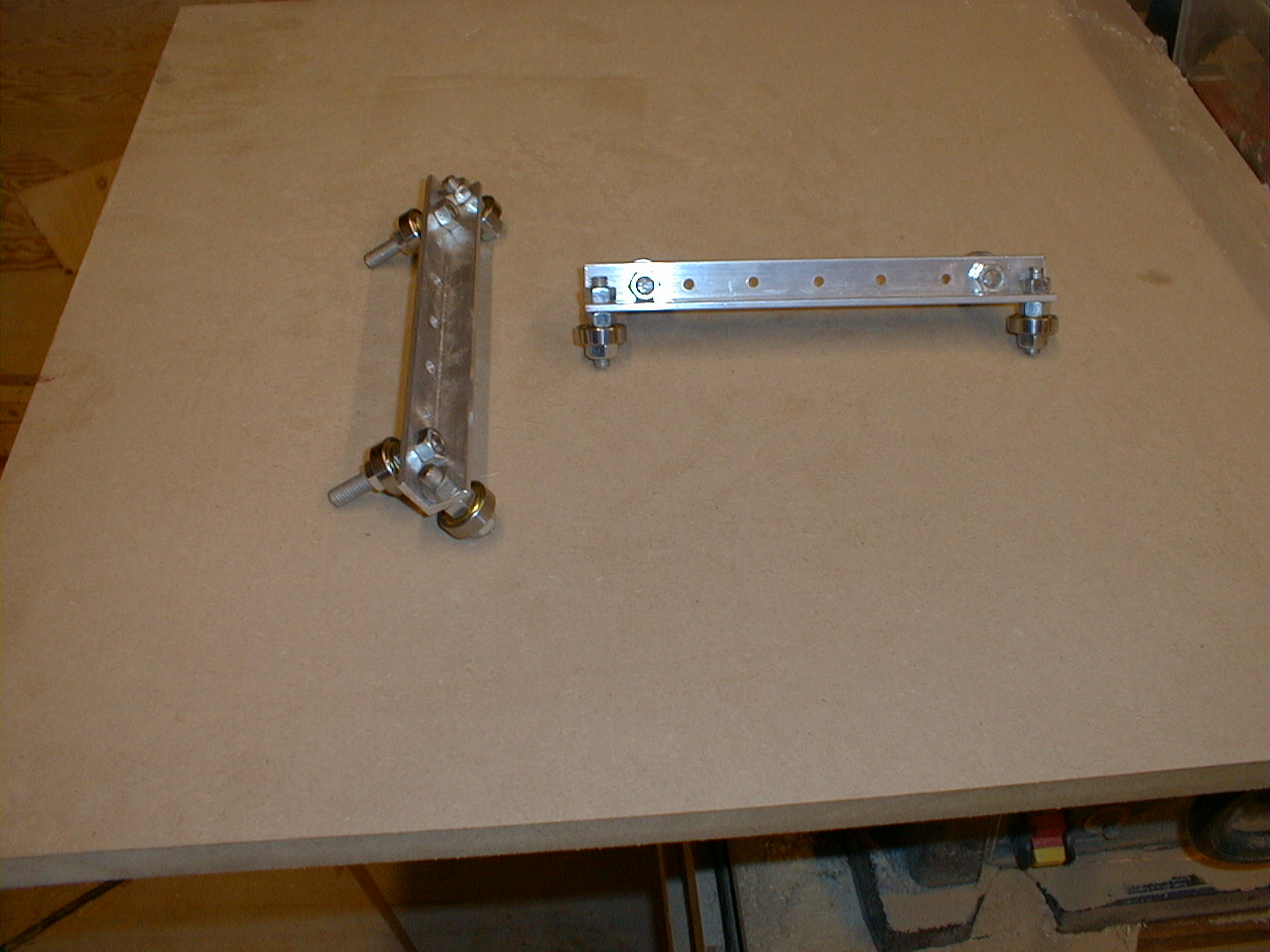

The Gantry unit, and end pieces were all cut out of 3/4" MDF, and painted. The bracing for the Gantry unit was made from 3/4" aluminum angle and 3/4" steel bar stock. All the parts were drilled and assembled with #8 machine screws. Make sure to buy LOTS of #8 1 1/4 and 1 1/2" machine screws, nuts and washers. I was surprised at the number required during the assembly.

The Gantry unit uses a solid nut design that rides on the 1/4-20 ALL-Thread lead screw. I made this nut out of UHMW Plastic which I picked up at Princess Auto. A bag of off-cuts cost about $10CDN. This was bolted to the upper deck of the Gantry.

The lead screw was cut from the ALL-Thread, fed through the tapped plastic nut and captured in the end bearing with 1/4" nuts. The end bearing (1/4" I.D. purchased from Canadian Bearing) was glued into a Plexiglass bearing plate with epoxy. This seems to work well.

The gantry unit rides on roller skate bearings that were purchased at Canadian Tire. The pack of bearings cost around $40 CDN for 16 bearings. 8 bearings were used for the gantry. This design works far better than I had hoped. Once the gantry was placed on the gas pipe it rode extremely smooth. Alignment was relatively easy as John's design allowed for it. I would highly recommend buying John's plans as they outline alignment techniques. His design allows for easy alignment.

Check back soon as I am planning on putting up some pictures of the gantry.

That concludes the construction info.