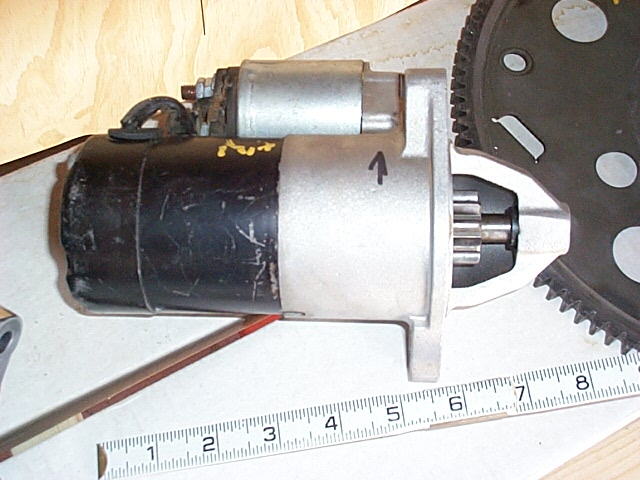

All 3 pieces: Starter and ring gear are from a Ford Probe 2.2L and

the alternator is from a Chevy Sprint |

I polished the alternator,

and painted the regulator cover.

It's my understanding that this unit is good for 60 amps. |

Very small starter. |

11" ring gear |

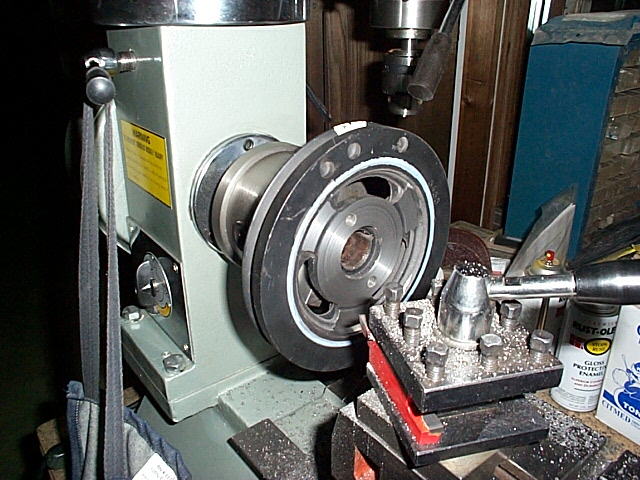

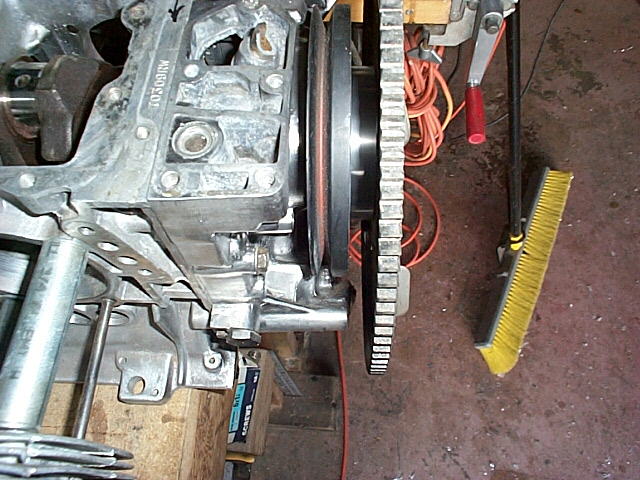

Facing the harmonic balancer. |

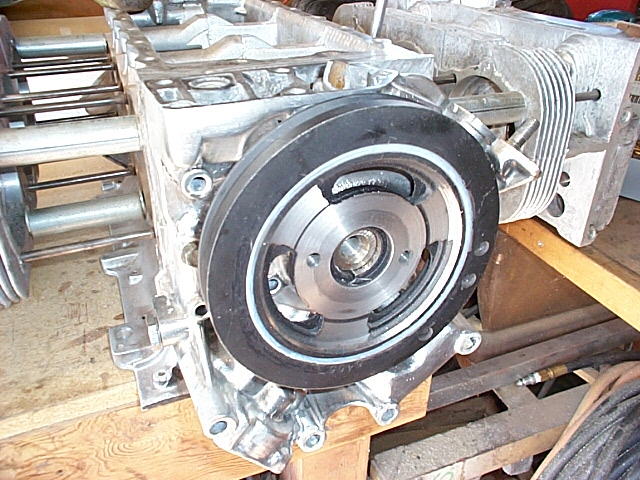

The studs holding the rear cover in place need to be removed or cut,

and the case cut back as well. I chose to remove my studs, but you can

see here how much of the case I had to remove. |

Harmonic balancer in

place, studs removed. |

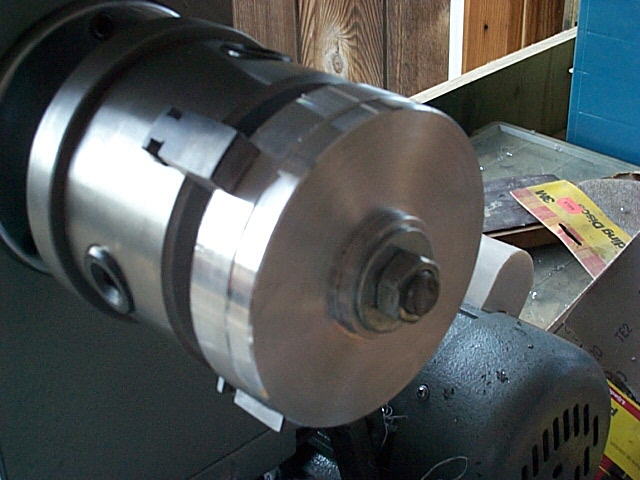

I found that if I ran a threaded rod through the lathe and nutted it at

both ends, I eliminated the chatter I was experiencing. This image shows the

threaded rod through the puck. |

...And this shot shows the other end of the rod and how it runs all the

way through the arbor. |

Here's the puck installed. It's a press fit into the harmonic

balancer.

I'll be drilling holes through the squash plate, to align with 1/2 of the

holes in the ring gear, into new holes tapped in the spokes of the harmonic

balancer. |

The ring gear is pressed on to the boss turned into the puck

A combination squash plate / alternator pulley will be machined and through-bolted to the

harmonic balancer spokes.

|

Here's the clearance between the back side of the teeth and the oil

pump. |

Here's the alternator mounted up. I needed it mounted to design

the pulley.

The bolt holding the ring gear in place is temporary. |

The bracket is temporarily mounted with 1 bolt. It'll become part

of the starter mount, probably the way Jon Crawford did his. It'll also be

relieved on the under side for the oil circuitry. |

| |

New

Stuff as of 4/30/00

The Starter is installed |

|

|

|

|