Solar Water Heating

Well-Proven Technology Pays Off in Several Situations

Abstract

Solar water heating is a renewable energy technology that is well proven

and readily available and has considerable potential for application at

federal facilities. Solar water-heating systems can be used effectively

throughout the country and most facilities will have an appropriate

near-south-facing roof or nearby unshaded grounds for installation of a

collector. A variety of types of systems are available and suitable for many

applications. For example, low-temperature unglazed systems can heat

swimming pools and associated hot tubs or spas, saving money on conventional

heating or extending the swimming season. In mild climates, passive systems

without pumps or electronic controllers can provide low-maintenance hot

water for facilities with limited or expensive utility service.

High-temperature parabolic-trough systems can economically provide hot water

to jails, hospitals, and other facilities in areas with good solar resources

that consistently use large volumes of hot water. And active flat-plate

systems can service any facility in any area with electric or otherwise

expensive conventional water heating.

This Federal Technology Alert (FTA) of the New Technology Demonstration

Program, one of a series of guides to renewable energy and new

energy-efficient technologies, is designed to give federal facility managers

the information they need to decide whether they should pursue solar water

heating for their facility and to know how to go about doing so. Software

available from FEMP's Federal Renewables Program at the National Renewable

Energy Laboratory (303-384-7509) gives a preliminary analysis of whether

solar water heating would be cost effective for your situation on the basis

of a minimal number of data.

This FTA describes the main types of solar water-heating systems

available and discusses some of the factors that make the various types more

or less appropriate for particular situations. It also points out the types

of situations where solar water heating is most likely to be cost effective

and gives examples for each of those situations. In addition, this FTA

outlines the basics of selecting, evaluating, procuring, funding and

maintaining a solar water-heating system. Sidebars highlight indicators that

a system will be effective, tips for ensuring successful operation, and

pointers for determining system data. A case study for a National Park

Service facility includes economic evaluation data and bid specifications.

References include solar water-heating collector manufacturers and system

distributors and contacts for federal facilities that are using solar water

heating.

About the Technology | Federal-Sector

Potential | Application

Technology Performance | Case Study

| The Technology in Perspective

Suppliers | Who is Using the

Technology

For Further Information | Appendixes

| Contacts | Disclaimer

(Back to Table of Contents)

About the Technology

An estimated one million residential and 200,000 commercial solar

water-heating systems have been installed in the United States. Although

there are a large number of different types of solar water-heating systems,

the basic technology is very simple. Sunlight strikes and heats an

"absorber" surface within a "solar collector" or an actual storage tank.

Either a heat-transfer fluid or the actual potable water to be used flows

through tubes attached to the absorber and picks up the heat from it.

(Systems with a separate heat-transfer-fluid loop include a heat exchanger

that then heats the potable water.) The heated water is stored in a separate

preheat tank or a conventional water heater tank until needed. If additional

heat is needed, it is provided by electricity or fossil-fuel energy by the

conventional water-heating system. By reducing the amount of heat that must

be provided by conventional water-heating, solar water-heating systems

directly substitute renewable energy for conventional energy, reducing the

use of electricity or fossil fuels by as much as 80%.

Today's solar water-heating systems are well proven

and reliable when correctly matched to climate and load. The current market

consists of a relatively small number of manufacturers and installers that

provide reliable equipment and quality system design. A quality assurance

and performance rating program for solar water-heating systems, instituted

by a voluntary association of the solar industry and various consumer

groups, makes it easier to select reliable equipment with confidence. After

taking advantage of possible use-reduction measures (see the

First Things

First sidebar), federal facility managers should investigate installing

solar water-heating systems.

Application Domain

Water heating accounts for a substantial portion of energy use at many

federal facilities. Nationwide, approximately 18% of energy use in

residential buildings and 4% in commercial buildings is for water heating.

Federal facilities with large laundries, kitchens, showers, or swimming

pools will likely devote even more energy to water heating. Solar water

heating systems can efficiently provide up to 80% of the hot-water needs of

many federal buildings—without fuel cost or pollution and with minimal

operation and maintenance expense.

Solar water-heating systems are most likely to be cost effective for

facilities with water-heating systems that are expensive to operate or with

operations such as laundries or kitchens that require large quantities of

hot water. A need for hot water that is relatively constant throughout the

week and throughout the year, or that is higher in the summer, is also

helpful for solar water-heating economics. On the other hand, hard water is

a negative factor, particularly for certain types of solar water-heating

systems, because it can increase maintenance costs and cause those systems

to wear out prematurely.

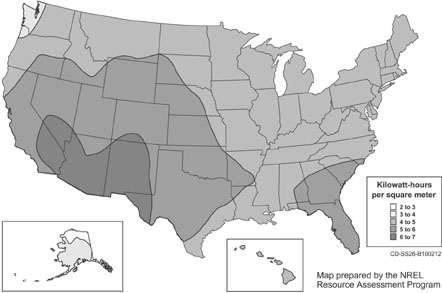

Figure 1. Average Daily Global Solar Radiation (on a south-facing flat

surface tilted at latitude, resource for all but parabolic troughs). Solar

water heating can be used effectively throughout the country. Available

solar radiation is the most important, but not the only factor for

cost-effective use.

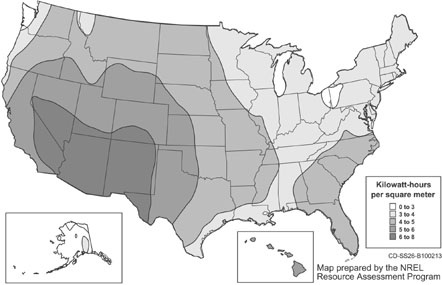

Figure 2. Average Daily Direct Normal Solar Radiation (on a tracking

surface always facing the sun, resource for parabolic trough).

Parabolic-trough solar water heating can be very effective for large

systems, but is best suited to areas with high direct solar radiation.

Solar water heating can be used effectively throughout the country. The

dominant factor in determining effectiveness for solar water heating is the

available solar resource (see Figure 1 and Figure 2), but do not dismiss the

possibility of using solar water heating because the facility is in a cloudy

area. Other factors are also quite important and solar water heating works

better than might be expected in areas with lesser solar resources. Cold

water supply temperatures (see Figure 3 and Appendix A increase system

efficiency because until the fluid being heated reaches higher temperatures,

it loses less heat to the surroundings. Cold air temperatures hurt solar

water-heating performance by increasing loss of heat from the collectors to

the air. Figure 4 shows the performance that can be expected by average and

good solar collectors, respectively, in various parts of the country.

Figure 3. Ground Water Temperature in °F in Wells Ranging from 50' to

150' Depth. Water supply temperature is also an important factor for solar

water heating. Cost-effectiveness is better if water must be heated from a

colder starting temperature.

Figure 4. Important factors for solar water-heating performance

include solar resource, air temperature, water supply temperature, and

collector efficiency.

Benefits

By tapping available renewable energy, solar water heating reduces

consumption of conventional energy that would otherwise be used. Each unit

of energy delivered to heat water with a solar heating system yields an even

greater reduction in use of fossil fuels. Water heating by natural gas,

propane, or fuel oil is only about 60% efficient and although electric water

heating is about 90% efficient, the production of electricity from fossil

fuels is generally only 30% or 40% efficient. Reducing fossil fuel use for

water heating not only saves stocks of the fossil fuels, but eliminates the

air pollution and climate change gas emission associated with burning those

fuels.

Energy-Saving Mechanism

Although solar water-heating systems all use the same basic method for

capturing and transferring solar energy, they do so with such a wide variety

of specific technologies that one almost needs to learn a whole language of

terms for distinguishing different collectors and systems. The distinctions

are important though, because various water-heating needs in various

locations are best served by certain types of collectors and systems.

Systems can be either active or passive, direct or indirect, pressurized or

nonpressurized. (Note: the terms open-loop and closed-loop are

frequently used to distinguish between direct and indirect systems, but

technically their meaning is more equivalent to nonpressurized and

pressurized. To avoid confusion, we will not use them here.)

Types of Systems

The most frequently used systems for large facilities, antifreeze

systems, are active, indirect systems. Active solar water-heating

systems use pumps to circulate a heat-transfer fluid between the collector

and the storage tank. Indirect active systems use a heat exchanger to

transfer heat from the circulating fluid to the potable water. Antifreeze

systems circulate a non-toxic fluid, usually propylene glycol, through the

collector. See Figure 5 or Appendix H.

Figure 5. Active, Indirect, Two-Tank Antifreeze System

Even in freezing climates, however, water is often the heat-transfer

fluid of choice. This is because water has excellent heat-transfer

properties, it is noncorrosive and highly stable, and it is less expensive.

The need to prevent the system from freezing is, of course, the trade-off

for using water as the heat-transfer fluid. The drain-back system

does this by totally draining the heat-transfer fluid out of the collector

loop whenever the pump is off, which is whenever the water in the collector

is not hot enough to heat the potable water, and therefore also whenever

there is any freeze danger. See Figure 6 or Appendix I. In contrast to most

indirect systems, which are pressurized, many drain-back systems use

a nonpressurized heat-transfer-fluid loop. Nonpressurized systems may

use plastic or site-built tanks that are less expensive and more durable

than pressurized metal tanks. Evaporated water must be replaced and being

open to the air poses greater corrosion potential, but for a large system

there may be significant savings with a nonpressurized tank.

Figure 6. Active, Indirect, Two-Tank Drain-Back Systems

Direct active systems run the potable water to be consumed

directly through the collector. Because they do not require a heat

exchanger, they average 5%-10% greater efficiency, but they must, in turn,

activate special mechanisms to prevent the system from freezing. When

control systems sense potential freeze conditions, valves on drain-down

systems shut the service water off from the collector loop water and allow

the collector loop water to drain out into a sump or down a drain.

Recirculating systems respond to freeze danger by pumping heated water

through the collection loop. Although freezing problems have been documented

with both of these direct systems in the past, a newly designed valve for

the former and careful choice of the right situations to use the latter may

prevent those problems. Hard water is particularly troublesome for direct

systems, because scale deposits that form in the collectors can reduce

efficiency, increase the likelihood of freeze damage by restricting flow,

and eventually shut down a system.

For smaller systems in mild climates with modest freeze threat,

passive systems are also a viable option. Passive systems do not require

pumps or electronic controls, greatly simplifying operation and maintenance,

making passive systems very attractive for certain situations. These are, in

fact, the most commonly used system types in climates with modest freeze

threat. However, because they usually store water outside at or near the

collector, these systems are subject to greater heat loss. In cold climates

particularly, this heat loss reduces the efficiency of the system in terms

of the percentage of the solar energy originally absorbed that is eventually

used.

Of the two main types of passive systems, integrated collector systems

(ICS) store the heated water inside the collector itself. Thermosiphon

systems have a separate storage tank directly above the collector. In direct

thermosiphon systems, the heated water rises from the collector to the tank

and cool water from the tank sinks back into the collector. In indirect

thermosiphon systems, heated antifreeze rises from the collector to an outer

tank that surrounds the potable water storage tank and acts as a heat

exchanger (be sure meets any code stipulations about double-wall heat

exchangers for separation from potable water). See Figure 7 or Appendix J.

In both ICS and thermosiphon systems, good insulation of the collector or

tank helps prevent freezing and heat loss at night. The critical links,

however, are the pipes connecting the collector or tank to the service water

inside the house. Depending on pipe size and insulation, they can withstand

temperatures that are only so far below freezing for only so long, so the

geographic areas where these passive systems may be safely used must be

carefully calculated. Hard water is again a concern. Also, most roofs will

support the substantial weight of the water storage, but this consideration

cannot be ignored in adding a system to an existing structure or in

designing a new facility.

Figure 7. Passive, Indirect Thermosiphon System

Types of Collectors

The principal component of a solar water-heating system—the collector—can

be low-temperature, mid-temperature, or high-temperature. The glazed,

flat-plate collectors most commonly used for commercial or residential

domestic hot water are classified as "mid-temperature" collectors,

generally increasing water temperature to as much as 160°F (71°C). As shown

in Figure 8, flat- plate collectors consist of an insulated, weather-tight

housing or box, a clear glass or plastic cover glazing, a black absorber

plate, and a system of passages for the heat-transfer fluid to pass through

the collector. Special coatings on the absorber maximize absorption of

sunlight and minimize re-radiation of heat. Gaskets and seals at the

connections between the piping and the collector and around the glazing

ensure a water-tight system.

Figure 8. Flat-Plate Collector

"Low-temperature" collectors, which generally increase water

temperature to as much as 90°F (32°C), are less expensive because they

consist simply of an absorber with flow passages and have no covering glass

(glazing), insulation, or expensive materials such as aluminum or copper.

These collectors are less efficient in retaining solar energy when outdoor

temperatures are low, but are quite efficient when outside air temperatures

are close to the temperature to which the water is being heated. They are

highly suitable for swimming pool heating and other uses that require only a

moderate increase in temperature and are most commonly used in warmer areas.

For the last several years, they have been the most frequently installed

collectors. In warm climates, low-temperature collectors are sometimes used

in hybrid systems that heat a pool in the winter and supplement domestic

water-heating in the summer, when pool heating is not needed.

Large federal facilities or ones with quasi-industrial operations such as

laundries may be able to efficiently use more sophisticated

high-temperature collectors. Although they are also used in

mid-temperature systems, evacuated-tube collectors can be designed to

increase water/steam temperatures to as much as 350°F (177°C). They may use

a variety of configurations, but generally encase both the absorber surface

and the tubes of working fluid in a tubular glass vacuum for highly

efficient insulation. See Figure 9. Evacuated-tube collectors are the most

efficient collector type for cold climates with low-level diffuse sunlight.

They can be mounted either on a roof or on the ground, but they need to be

protected from vandalism and can be damaged by hail or hurricanes.

Figure 9. Evacuated Tube Collector

Parabolic-trough collectors use curved mirrors to focus the

sunlight on a receiver tube (sometimes encased in an evacuated tube) running

through the focal point of the mirrors and can heat their transfer fluid to

as much as 570°F (299°C). See Figure 10. Because they use only direct-beam

sunlight, parabolic-trough systems require tracking systems to keep them

focused toward the sun and are best suited to areas with high direct solar

radiation. See Figure 2. Because they are particularly susceptible to

transmitting structural stress from wind loading and require large areas for

installation, parabolic-trough collectors are usually ground mounted. For

electrical generation or industrial uses that require very high temperatures

(greater than 392°F [200°C]), a heat-transfer fluid such as an oil is used,

but depending on the degree of danger of freezing, antifreeze or water is

used in the heat-transfer loop for domestic water-heating systems.

Parabolic-trough collectors generally require greater maintenance and

supervision and particularly benefit from economies of scale, so are

generally used for larger systems.

Figure 10. Parabolic trough solar water-heating system for Adams

County, Colorado, Correctional Facility

System Design

System design for solar water-heating systems seeks to effectively

combine solar water-heating with conventional water-heating. Rather than

trying to store enough hot water to last through a long period of cloudy

weather, solar water-heating systems generally have conventional

water-heating systems as backup. Exceptions, such as the Chickasaw National

Recreation Area systems cited later as a case study, are situations in which

a lack of hot water for a few days is acceptable and the expense of

conventional backup is not justified. Typically, a conventional hot-water

heater draws preheated water from the solar water-heating system storage

tank. If that preheated water is not hot enough, the conventional water

heater operates as it would if it were starting with cold water and further

heats the water until it reaches its set delivery temperature. Occasionally,

the solar-heated water (up to 180°F [82°C]) is too hot for safe use, so it

is mixed with cold water in a tempering valve.

As shown in Figure 5 a typical active, indirect solar water-heating

system consists of one or more parallel-connected glazed flat-plate

collectors, a storage tank, a heat exchanger, piping and valves for the

heat-transfer fluid and for the potable water, pumps, and controls. Whenever

the temperature of the water in the collector exceeds that of the stored

water by more than a certain amount (usually about 12°F [6°C]), the

"controller" (a) turns on both pumps (b and c). The heat-transfer-fluid

system pump (b) circulates heated antifreeze from the collectors to the heat

exchanger (where it transfers heat to the potable water) and back to the

collectors. The potable water system pump (c) circulates cool water from the

bottom of the storage tank to the heat exchanger for heating and then back

to the top of the storage tank. (Instead of having a separate heat exchanger

unit, the heat-transfer fluid may "wrap around" the potable water storage

tank either with piping or with a surrounding outer tank.) As water is used

from the conventional hot-water tank, it is replaced by solar-heated water

from the top of the storage tank. Inlet water from the domestic supply

system flows into the bottom of the storage tank to keep the system full.

Alternatively, a single storage tank may be used. A common single-tank

design disconnects the heating element(s) from the lower portion of a

conventional electric water heater. When the solar water-heating system is

operating, it draws cold water from the bottom of the tank and returns the

heated water to the top. If the solar heating does not have the water hot

enough, the conventional heating elements in the top of the tank bring the

water up to the desired temperature. Although not used much in this country,

another single-tank design uses a rapid booster or "tankless" heater in the

water line as it leaves the tank to provide additional heating upon demand,

if needed. This option avoids maintaining the whole tank at the desired

temperature as most conventional water heaters do, minimizing standby

losses. Some two-tank systems add a second direct pipe connection with

appropriate check valves between the two tanks to increase heat flow from

the solar storage tank to the conventional tank. If the solar storage tank

is hotter than the conventional water service tank, hot water flows by

convection into the service tank, even when there is no draw on the system.

The most cost-effective size for a solar water-heating system will often

be one that is just sufficient to meet the full summer demand and that meets

approximately two-thirds of the year-round demand. Including enough capacity

to meet more of the winter demand reduces cost-effectiveness both because

excess capacity is wasted in the summer and because it is increasingly

difficult to serve each additional portion of the winter demand with the

reduced solar resource. The most cost-effective size can vary widely with

specific circumstances, however, and for commercial building systems

especially, it is sometimes best to plan to supply considerably less than

two-thirds of hot-water use. The key factors in determining the most

cost-effective size for a system are the type and cost of conventional fuel

and the cost of the solar water-heating system to be installed.

Good records of past hot-water use help greatly to plan an effective

solar water-heating system, and it is easy to install a water meter on the

incoming line to a hot-water heater. Water use can vary quite substantially,

but for new construction, or if your uses of hot water are relatively

"standard," there are "rules of thumb" to estimate hot-water requirements

for various building uses. The handbook guideline for residential use, for

example, is 20 to 30 gallons per person or 65 gallons per household per day.

(Note, however, that some more recent studies have found average use as low

as 25-35 gallons per household per day.) For office buildings, you can

expect hot-water use of 0.5 gallon per person per day. (The standard

reference for projecting hot-water use is the American Society of Heating,

Refrigerating, and Air-Conditioning Engineers, Inc. [ASHRAE] Applications

Handbook, Chapter 44.)

The circumstances for specific large facilities may vary considerably,

but for small systems, a general rule of thumb is to have storage roughly

equal to one day's hot-water use. In a location with average available solar

energy, you will need approximately 0.5 to 1.0 square feet of flat-plate

collector per gallon of storage tank. The daily pattern and consistency of

hot-water consumption is also an important consideration for determining the

size of collector and storage area needed. Uses that demand hot water mostly

during the day (laundries, lunch service, or car washes, for example) will

require relatively less storage than uses such as showers for which the

heaviest demand occurs at night or early in the morning.

Installation

Solar collectors can be mounted on the roof of a building or on nearby

grounds. For year-round uses, the most efficient orientation for the

collector is facing south, tilted at an angle about equal to the latitude of

the site. (The latitude plus 15° maximizes wintertime heat collection and

latitude minus 15° maximizes summertime heat collection.) Collectors can be

tilted to the proper orientation with mounting racks. For cost savings and

aesthetic reasons, however, they are increasingly being laid flat against

pitched roofs. If the orientation is at all close to optimal, the sacrifice

in available energy is usually quite modest. For Denver, Colorado, for

example, with a tilt of latitude minus 15°, mounting the collectors as much

as 45° off of southern orientation loses at most 10% of available solar

energy. Similarly, with a true southern orientation, you can mount

collectors at up to 25° off latitude tilt with only 10% loss. Solar resource

information for Boulder, Colorado, is presented in Appendix B as an example

of available data.

Incorporating solar water-heating systems in new construction has the

advantages of ensuring that there is an appropriate roof for collector

placement, allowing for aesthetic design, and reducing installation costs.

If the builder, architect, or engineer is used to working with solar

water-heating, it can also save on design cost. But, almost any building can

incorporate a solar collector retrofit. It is relatively easy to add a solar

water-heating system to an existing facility and the economics will be

nearly as good.

There are generally relatively few special regulations to consider in

installing solar water-heating systems, but there are pertinent building,

mechanical, and plumbing codes. Areas with special building regulations

because of earthquake or hurricane danger, might have structural

requirements limiting the weight or type of equipment that can be placed on

a roof. Some local codes for residential or commercial areas regulate the

attachment of collectors to roofs or walls. A few jurisdictions require

rigorous separation between the heat-transfer fluid and the potable water in

closed-loop systems that could rule out single-wall heat exchangers. Besides

regulations such as these, systems need only comply with standard plumbing

and local building codes.

Numerous manufacturers make quality solar collectors and solar

water-heating systems. In addition to checking out the various

manufacturers, one way to ensure that your system meets generally applied

standards is to install an Solar Rating and Certification Corporation (SRCC)-certified

system. An independent, nonprofit organization created by organizations

representing solar equipment manufacturers, state governments, and

consumers, the SRCC has instituted a quality assurance and performance

rating program. As of December 1995, the SRCC had certified three unglazed

collectors and 60 glazed flat-plate collectors made by a total of 12

different manufacturers, plus 78 total solar water-heating systems made by

12 different manufacturers. The SRCC certification process also ensures that

health and safety issues have been addressed, that typical code provisions

are complied with, and that durability and reliability standards have been

met and are correctly portrayed. There, of course, may be collectors and

systems of acceptable quality that have not been rated by SRCC.

A complete list of all solar collector and water-heating system

manufacturers was not available, but "Suppliers" lists the manufacturers of

the SRCC-certified collectors and systems plus manufacturers who belong to

the Solar Energy Industries Association. You can also check the Thomas

Register of American Manufacturers. The Energy Information Agency's

annual survey, reported in the Renewable Energy Annual, reports 41

active solar collector manufacturing companies shipping 7.6 million square

feet of collectors in 1994. Information on SRCC-certified systems is

contained in the Directory of SRCC Certified Solar Collector and Water

Heating System Ratings. Appendix G, Appendix H, Appendix I, and Appendix

J illustrate SRCC collector and system rating information. (The Florida

Solar Energy Center also rates solar water-heating systems.)

(Back to Table of Contents)

Federal-Sector Potential

Technology Screening Process

The Federal Technology Alert (FTA) series targets technologies that

appear to have significant untapped federal-sector potential and for which

some federal installation experience exists. Many of the alerts are about

new technologies identified through advertisements for technology

suggestions in the Commerce Business Daily and trade journals, and

through direct correspondence in response to an open technology

solicitation. Those technologies are then evaluated in terms of potential

energy, cost, and environmental benefits to the federal sector.

Solar water heating is a renewable energy technology with clearly known

energy, cost, and environmental benefits, and a large number of

manufacturers of a variety of products—but still with substantial untapped

potential for the federal sector. Solar water heating was selected for the

New Technology Demonstration Program through response to the open technology

solicitation.

Estimated Market Potential

The Office of Technology Assessment reported in 1991 that the U.S.

Government owns or leases approximately 500,000 buildings, owns an

additional 422,000 housing units for military families, and subsidizes

utility bills for nine million private households. If the objective were to

reduce fossil fuel energy use and associated pollution, regardless of

cost-effectiveness, the potential application of solar water heating would

clearly be immense. Even limiting application to cost-effective situations,

opportunities for solar water heating may still be quite substantial.

Combining the large number of military and other housing units with the fact

that 18% of residential energy use is for water heating and an Energy

Information Administration statement that 38% of U.S. residential water

heating is electric, points to a very large potential application for small

systems where economics are likely to be attractive. Federal prisons,

hospitals, and barracks are ideal situations for large, high-temperature

systems to prove cost effective. An estimate of the number of swimming pools

at federal facilities is not available, but there are certainly a

significant number and the likelihood of solar pool heating being cost

effective is quite good.

(Back to Table of Contents)

Application

The cost of operating conventional or backup water-heating systems is the

single most important factor in determining economic feasibility for solar

water-heating systems, but a variety of other factors are also important.

Solar water-heating projects for federal facilities are most likely to be

cost effective in three situations:

- Small, "residential-size" facilities such as visitor centers,

campground showers, or staff housing, which would otherwise be dependent

upon high-cost energy sources

- Large facilities that require large volumes of hot water (more than a

thousand gallons per day) or have operations that use high-temperature hot

water

- Swimming pools.

Where to Apply—Small Facilities

For small federal facility projects, the cost of conventional

water-heating systems dominates the economic feasibility of solar

water-heating systems. As can be seen from

Table 1, the cost of conventional energy varies greatly. Note that these

figures are national averages and utility rates vary greatly by region and

individual facility contract. There may be regions in which the relative

effective energy cost of the various energy supplies differs from that

below.

Table 2 shows average utility rates by region. Water heater efficiencies

also vary significantly, particularly for larger heaters, from 77% to 97%

for electric and from 43% to 86% for gas. You should therefore also

investigate the cost effectiveness of buying a more efficient water heater

either on its own or in conjunction with installation of a solar

water-heating system.

The cost of solar water-heating systems can vary widely depending upon

the circumstances for a specific installation, region of the country, and

other factors and are not generally available as published numbers. To get a

ballpark idea, however, we can look at four residential-size systems

approved by the Sacramento Municipal Utility District for its

electrical-demand-reduction incentive program. The four systems are a

42-square-foot indirect thermosiphon system, an evacuated-tube integrated

collector system, a 64-square-foot antifreeze system, and a 40-square-foot

antifreeze system that uses a "wraparound" heat exchanger so it needs only

one pump instead of two. The systems vary in cost from $2,860 to $3,180 and

from meeting 61% to 74% of an assumed 57-gallon-per-day demand (averages 8.8

MBtu per year delivered energy). If we assume 20-year continuous operation

and 0.5% per year operation and maintenance cost for the two passive systems

and 2% per year for the two active systems, the levelized cost for the

systems falls in the $20 to $23 per MBtu range. Looking at Table 1 and Table

2, we can see that this is less than the average cost of electricity for

federal facilities, nationally and for several of the regions, but there is

little chance of competing with other types of water heating.

As it happens, many smaller federal facilities or elements of federal

facilities are located in relatively remote areas where conventional

water-heating utility costs are particularly high. Three-quarters of the

projects built in the 1980s under the Solar in Federal Buildings Program

were small systems (less than 100 square feet of collector) for facilities

in the National Park System. Any of the mid-temperature technologies will

work well for small facilities. Solar water-heating works well for general

domestic needs and for isolated facilities such as laundries, showers,

visitor centers, ranger stations, and staff housing.

"Off-the-shelf" packages are often quite appropriate for small or remote

facilities such as these, and a variety of SRCC-certified systems are

available, so engineering design work is not necessary. If the potential

system involves more than two or three collectors or will be connected to

unusual plumbing, electrical, or structural systems, a bid package will

likely be needed for a specific design. But in most cases, you will still be

able to use off-the-shelf components and the ASHRAE Active Solar Heating

Systems Design Manual.

In warm climates with limited freeze danger, the low-maintenance nature

of passive systems is an attractive feature for isolated locations. Solar

electric cells can provide power to operate solar water-heating systems if

electric utility connections are unavailable. Even if grid electricity is

available, solar cells are an excellent match for solar water-heating pumps

and often are used as the main operation control for the system. When there

is enough sunlight for the hot-water system to be operating and power is

needed to run the pumps, the solar cells are also producing power.

Where to Apply—Large Systems

Although the cost of conventional energy is still the most critical

factor for the economics of solar water-heating systems, for large federal

facilities, it is less likely to be the factor that makes solar

water-heating cost effective. Because of their size and because they are

less likely to be in remote locations, most large facilities will have

moderate or low-cost energy available. The cost-effectiveness of solar

water-heating systems for large facilities may, however, be improved

significantly by economies of scale in building a large system. While small

systems with less than 100 square feet of collector generally cost between

$50 and $90 per square foot of collector aperture, that figure can drop to

$40 or $45 per square foot for flat-plate collector systems with more than

1000 square feet of collector, $30 per square foot for systems with more

than 10,000 square feet of collector, or even $25 per square foot for

parabolic-trough systems with more than 20,000 square feet of collector.

As can be seen from

Table 3, that reduction in cost can make all the difference in whether a

project will beat out the conventional energy costs cited above. The table

divides total system cost (including 2% per year operation and maintenance)

by the amountof energy the system would produce over a 20-year lifetime.

These costs do not include government acquisition costs, which tend to be

relatively constant regardless of project size, giving further advantage to

larger projects.

As can be seen by comparing Table 1 and Table 3, none of our six sample

cities can compete with conventional water heating paying the effective

national-average cost for electricity of $23.13/MBtu with small solar

water-heating systems costing $75 to $90 per square foot of collector and

only two at $60 per square foot. But with a larger system costing $40 or $50

per square foot, solar water-heating is quite competitive. These numbers

are, of course, ballpark figures that do not take into account the specifics

of particular situations, but they do illustrate the importance of either

competing against expensive conventional water-heating or having a large

water-heating load that allows building a large enough solar water-heating

system to bring costs down.

If hot water use is more than 1000 gallons per day or conventional energy

cost is more than $15 to $20 per million Btu, prospects are good for a large

solar water-heating system to prove cost effective. At more than 10,000

gallons per day, parabolic-trough systems should be considered.

Nearly all prisons, hospitals, and military bases, and many other federal

facilities with kitchens, laundries, or showers, use large quantities of hot

water. Many of these facilities also have populations that are constant

throughout the week and throughout the year and therefore have consistent

water use. These factors make it worthwhile to consider a solar

water-heating system—particularly if conventional energy costs are

relatively high. As indicated by the case study below, additional savings

are often possible during the summer by recovering heat from chiller

systems. It is occasionally possible to take further advantage of economies

of scale by also providing hot water for space heating or cooling or other

purposes. Current thinking, however, is to look first at providing just for

direct hot water use, because adding heating or cooling makes systems more

complex and may adversely affect economics by increasing the variation in

demand throughout the year.

Active indirect systems with flat-plate collectors work well for meeting

large water-heating demands, but larger water volumes and need for

high-temperature water also make high-temperature parabolic-trough or

evacuated-tube systems attractive, depending on the climate. While

flat-plate collector systems typically provide enough heat to efficiently

raise heat transfer fluid temperatures to as much as 160°F (70°C), the

high-temperature collectors operate more efficiently when generating water

or steam at much higher temperatures—up to 350°F (175°C) for evacuated-tube

collectors and up to 570°F (300°C) for parabolic-trough collectors. So these

systems are particularly good for facilities with high-temperature water

needs such as laundries, which typically use water as hot as 180°F (82°C);

kitchens, which typically use water temperatures from 140°F to 195°F (60°C

to 91°C) for dishwashing; or industrial processes.

Where to Apply—Swimming Pools

One of the most consistently cost-effective uses for solar water-heating

systems is for heating swimming pools. Low-temperature collectors—most of

which are for swimming pools—have accounted for the majority of solar

water-heating systems sold since 1991 (more than 85% on a square-foot basis

in 1993). Many military bases and other federal facilities have swimming

pools, so there may be many cost-effective opportunities for installation of

solar swimming pool heaters. If you have a pool and it is now heated, you

may reap great savings, because solar pool-heating systems frequently pay

for themselves within 2 to 4 years—even when replacing natural gas heat. If

your pool is not now heated, you may be able to extend your season by

several months. If you are faced with budget cuts, energy savings may allow

you to keep a pool open.

The pool's filter system pumps the water through the collector and the

heat storage is in the pool itself. Because only a modest temperature

increase is needed, most systems use inexpensive, unglazed low-temperature

collectors, which are often essentially systems of water tubes built into

dark plastic. "Off the shelf" packages are generally appropriate and

maintenance is minimal. Some smaller systems are operated manually or with

timers, but larger systems are operated by electronic sensors and controls.

When the collector temperature is sufficiently greater than the pool

temperature, a diverting valve—the only moving part—diverts water from the

filter system through the collector loop. As with other hot-water uses,

conservation of generated heat is generally the most cost-effective

investment and swimming pool covers should be considered at the same time as

a solar water-heating system.

Brochures on covers and solar water-heating systems for swimming pools

and a software package that can evaluate the economic feasibility for your

pool are available from the Energy Efficiency and Renewable Energy

Clearinghouse. Call 1-800-DOE-EREC and ask for the "Energy Smart Pools"

package.

Application Screening

The first step toward installing a solar water-heating system is to

assess your hot-water needs. How much hot water at what temperature do your

various facilities use (or are new facilities expected to use), on what kind

of schedule? How much do you pay for the energy to heat that water? Can you

save money with a more efficient conventional water heater? What options do

you have for reducing hot-water use or lowering the temperature of water

provided?

The next step is to obtain a preliminary estimate of whether solar

water-heating will be cost effective. The FEMP Federal Renewables Program at

the National Renewable Energy Laboratory has developed a computer program

known as Federal Renewable Energy Screening Assistant (FREScA) that can make

such a preliminary assessment for you. See "How

Do You Figure" for a list of the necessary information. (For swimming

pools, you can use "Energy Smart Pools" software instead of FREScA.)

For smaller projects, a clearly positive FREScA calculation will often be

sufficient to proceed to system purchase. For large systems, a positive

FREScA assessment should be followed up with a formal feasibility study (see

"Economic Criteria"). Larger projects will likely

require a private engineer at some point, but the FEMP Federal Renewables

Program staff can provide fairly extensive assistance.

A general rule of thumb for federal facilities is that a renewable energy

installation should pay for itself within about 10 to 15 years. Because the

lifetime of a system can be as much as 30 years, that means you can look

forward to as much as 20 years of "free energy."

System Selection and Procurement

As a general rule, the optimal type of solar water-heating system depends

on the increase in water temperature that the system will be used for.

Low-temperature systems—with no cover glazing or insulation—absorb a high

percentage of the available solar heat but also lose sizable amounts of

energy. They are therefore best for uses such as swimming pools that only

require a modest increase in water temperature. Adding glazing and

insulation cuts down on heat absorption but greatly increases heat

retention, so the added cost of mid-temperature systems is cost effective

for most applications requiring greater increases in water temperature.

High-temperature systems, such as evacuated tubes with their very high

insulation and parabolic troughs with their concentration of the sunlight,

are most effective when used to provide either very large amounts of hot

water or high temperature uses such as kitchens, laundries, or industrial

uses. (See "The

Right Collector for the Right Use" for detailed discussion.)

Table 4 summarizes characteristics that may make certain system types

particularly suitable or inappropriate for your facility.

Having found that a solar water-heating system is likely to be cost

effective for your facility, chosen one or two appropriate system types, and

determined the approximate size of the system, you can now probably pick out

the most appropriate products from the SRCC Directory (for smaller

systems) and proceed toward purchase in accordance with Federal Acquisition

Regulations. For most agencies this means small purchase agreements based on

a request for quotes for projects costing less than $25,000, requests for

quotes including notice in the Commerce Business Daily for projects

costing from $25,000 to $50,000, and going out for bids for anything more

than $50,000. (A new electronic mail advertising system in the works will

allow requests for quotes to be used for anything up to $100,000.)

For smaller systems, specifics on your hot-water usage pattern, water

supply temperature, and detailed utility rate schedule will probably be

sufficient additional data for potential vendors to supply the cost,

performance, and other information you need to select a system and to decide

whether to proceed. It is not quite like going to the discount store for a

conventional home water heater, but complete off-the-shelf systems are

available. FEMP is working on getting solar water-heating systems on the GSA

purchase schedule (perhaps by 1997, check with the FEMP Help Line), which

will make it easier to obtain specific models at fixed prices. They are also

developing product recommendations for solar water-heating systems. In the

meantime, certified systems from the SRCC Directory are a place to

start, and there may be many other good systems to choose from.

For larger systems, you will need engineering help to select an optimum

system and do a detailed economic assessment for that system (see "Economic

Criteria") You may have to go out for bids to hire an engineer to design the

system, but can probably do so with a sole-source contract for professional

services. The designer cannot then be a vendor for the system but can write

the specifications for the bid request and either install or supervise the

system's installation. Appendix E is an example of specifications used for

the Chickasaw National Recreation Area case study. Check with the FEMP

Federal Renewables Program (303-384-7509) for other previously prepared

specifications that may be more similar to your planned system.

The policy for evaluating whether solar water-heating or other renewable

energy projects are cost effective and therefore appropriate for federal

facilities is contained in 10 CFR Part 436A of the Code of Federal

Regulations. The principal criterion of these regulations is that the

life-cycle cost (value in base-year dollars of all costs for the full

analysis period) for the project must be less than any alternatives,

including projected utility payments with the existing water-heating system.

(Three similar criteria may be used instead for retrofit projects, and

projects with "insignificant" cost are presumed cost effective.)

Executive Order 12902 goes beyond the cost-effectiveness regulations to

stipulate that if a project will pay for itself (simple payback period time

for savings to return the cost of the investment) in less than 10 years, it

shall be built (Sections 103 and 303). For most situations the 10-year

payback criterion will be more rigorous than the life-cycle-cost criterion.

Many projects will meet the life-cycle-cost criterion even though their

simple payback is somewhat longer than 10 years. Agencies must build

projects with a simple payback of less than 10 years, but may also build any

project that meets the life-cycle-cost criterion.

Life-cycle-cost analysis calculates the sum during the life of the

project of the present value of investment costs, operation and maintenance,

replacement costs, and energy costs, minus salvage value of replaced parts.

A manual for life-cycle costing (National Institute of Standards and

Technology [NIST] Handbook 135), an annual set of prescribed energy prices

and discount rates (NISTIR 85-3273), and Building Life-Cycle Cost (BLCC)

software (NIST 4481) are all available by calling the FEMP Help Line at

800-DOE-EREC. (Some agencies allow simpler life-cycle calculations, but the

BLCC is required if FEMP funding is involved. You may also need Mean's

Mechanical Cost Data [available from 800-448-8182] for estimating system

component costs.)

In addition to determining whether a project is cost effective, economic

analysis helps to determine the size of the solar water-heating project that

will minimize costs during the life of the project. The cost of conventional

water-heating options will usually be the biggest factor in determining

optimal project size. The higher the conventional water-heating cost, the

larger portion of the load you are likely to be able to meet effectively

with a solar water-heating system. Calculating the resulting savings in

conventional water-heating (subtracting any operation and maintenance cost

for the system) and using an appropriate discount rate or interest factor to

compare present system cost to future savings determines whether the system

is a worthwhile investment. The prescribed discount rate for evaluating

renewable energy projects for federal facilities for 1995 is 3%. A low

discount rate such as this favors future savings over initial investment—and

thus encourages renewable energy projects such as solar water-heating

systems.

Although standard life-cycle-cost analysis does not include a way to take

credit for environmental externalities such as benefits of reducing fossil

fuel consumption, these may be an important consideration if the economic

efficiency calculation is close. The National Park Service has developed

guidelines for calculating and including avoided air emissions resulting

from reduced electrical power production in their internal economic

evaluation of large energy efficiency and renewable energy projects (Doug

DeNio, 303-969-2162). Some agencies have chosen to relax the economic

evaluation criteria somewhat for showcase buildings in new facilities or

demonstration projects at existing facilities. Projects must be basically

cost effective, however, or else they do not make good demonstrations.

Funding Sources

The first place to look for funding is regular internal agency funding:

local purchasing authority for very small projects; Congressionally approved

line items for very large projects; and regular agency funding. Special

agency-specific funds, such as the Defense Department's Energy Conservation

Investment Program, may be available for energy efficiency and renewable

energy projects. Although there is not expected to be any funding available

for fiscal year 1996, the Federal Energy Efficiency Fund of the U.S.

Department of Energy (DOE) and other programs have provided funding

assistance for renewable energy projects at federal facilities in the past.

Call the FEMP Federal Renewables Program (303-384-7509) for the current

status of any available funding.

An important new financing option available to federal facilities is

energy savings performance contracting (ESPC). A private energy services

contractor designs and installs the system, paying the full cost of parts

and labor, or the project can be financed by a third party. The federal

facility pays nothing up front beyond initial feasibility studies. The

contractor is responsible for operating and maintaining the system and

training facility personnel in its use. The facility then pays the

contractor for the energy received as a discounted percentage (usually about

15% less) of what it would have cost from the utility. The facility pays

these "utility savings" bills for a specified contract period (up to 25

years) from its utility or operation and maintenance budget, after which the

facility retains the savings and equipment. Thus, the contractor and the

facility share the savings in utility costs. (There are now quite a few

companies set up to do energy service contracts; an association is listed on

page 24.) The facility must announce intent to consider ESPC proposals in

the Commerce Business Daily, but may accept unsolicited proposals.

The DOE has a list of prequalified energy service companies and model

procurement documents, as well as a manual on the ESPC program (for copies,

call the FEMP Help Line at 800-DOE-EREC).

Through 1995, 17 performance contracts at a total cost of approximately

$30 million have been awarded under the ESPC program (mostly energy

efficiency so far, but solar water-heating is clearly eligible). Both the

contractors and FEMP are developing a track record and experience base that

will help make projects go more smoothly. FEMP is currently working on

setting up indefinite quantity contracts to allow qualified contractors to

serve any eligible federal facility project within a region.

The obvious advantages of performance contracting are limited initial

investment, no capital investment, no operation and maintenance

responsibility, and no technical or financial risk for the success of the

project. ESPC contracting is especially attractive for very large projects

that require substantial capital outlay or extensive operation and

maintenance. However, if funds can be obtained to build a project, straight

agency funding brings the full cost savings back to the facility for the

life of the project. Also, even with prequalified contractors, the paperwork

necessary for performance contracting is significant enough to make it

unattractive for smaller projects for which construction can be more easily

funded.

More than half the states and many local governments do provide

incentives for solar thermal collector or solar cell system purchases. These

programs are not generally directly applicable to federal facilities, but

may be helpful in certain situations.

Utility company incentives for demand reduction and load management are

currently an important nonfederal source of financial assistance for solar

water-heating systems. Demand-side-management activities, such as promoting

solar water-heating systems, can save a utility from investing in system

expansions or help them comply with air quality programs. Among the

utilities that have been actively providing rebates or other financial

incentives for new solar water-heating systems are the Sacramento Municipal

Utility District, Florida Power and Light, and the Eugene Water and Electric

Board. Wisconsin Public Service and the Hawaiian Electric Company are

developing programs.

Although most programs such as these were designed for residential

customers, they also generally apply to commercial facilities including

federal buildings. Federal facilities may be able to negotiate specific

incentives for larger projects beyond the scope of standard programs or

where standard programs do not exist. On the one hand, anticipated utility

industry restructuring may cut back on demand-side-management programs, but

on the other, it may encourage utilities to spin off energy service

companies specifically set up to design and install energy efficiency and

renewable energy projects.

(Back to Table of Contents)

Technology Performance

An estimated one million residential and 200,000 commercial solar

water-heating systems have been installed in the United States. Seven

hundred and eighteen systems were installed at federal facilities during or

shortly after 1981 through the Solar in Federal Buildings Program. For

discussion of experiences with recent installations, see "Small

System Examples," "Large

System Examples," "Swimming

Pool Examples," and "Who Is Using the Technology." The technology is

well developed and today's solar water-heating systems are well proven and

reliable when correctly matched to climate and load. The current market

consists of a relatively small number of manufacturers and installers that

provide reliable equipment and quality system design. A quality assurance

and performance rating program, instituted by a voluntary association of the

solar industry and various consumer groups, makes it easier to select

reliable equipment with confidence.

Solar water-heating is a renewable energy technology that saves nearly as

much (there is usually some excess capacity) conventional energy use as it

produces. Water heating accounts for about 18% of energy use in residential

and 4% of energy use in commercial buildings. Solar water-heating can be

used to replace much of that electrical and fossil fuel energy consumption,

wherever it is found cost effective. Cost-effective system design often

matches hot-water use in the summer and partially meets the demand in winter

for a net production of about two-thirds of total hot-water use.

System Maintenance

Solar water-heating systems are long-lived and require relatively little

attention. But, as with any mechanical system, some basic maintenance is

essential to keep the system functioning smoothly. All solar water-heating

systems should be checked out at least twice per year. Proper operation of

sensors and controllers should be tested for active systems. A primary cause

of problems is calcium carbonate deposits (scaling) from hard water. Other

major maintenance concerns are pumps failing and tanks developing leaks. As

with conventional water heaters, pressurized hot-water tanks will have about

a 15-year lifetime. Ten-year warranties on collectors are the industry

standard.

Integrated collector and thermosiphon systems need little maintenance.

Relief valves ($10) will require replacement approximately every 15 years,

as with any hot-water system. Unless you have hard water, the systems should

not require flushing and should last 20 to 30 years. Direct thermosiphon

systems are not recommended for facilities with hard water. For integrated

collector and indirect thermosiphon systems, very hard water necessitates

additional maintenance and your contractor may suggest flushing or other

measures. The antifreeze in indirect thermosiphon systems should be replaced

every 5-10 years.

Direct active systems such as drain-down and recirculating systems are

also strongly affected by scaling and are not generally recommended where

water is hard. One way to combat scaling problems is to install an extra

anode rod in the water heater. (All conventional water heaters have anodes

and replacing them could extend service life, but they are often hard to get

at.) In addition, controllers and valves of direct active systems must be

very carefully maintained to prevent freezing problems.

Because drain-back systems are indirect and can use demineralized water

for the heat-transfer loop, scaling from hard water is not as serious. Only

the potable-water side of the heat exchanger requires cleaning. (It should

be checked every year or so until you have a sense of the scaling problem

for your water supply.) If the system is not pressurized, it may require

regular replacement of evaporated water or checking the valve that does

that. Sensors, controllers, and pumps should be checked regularly. Pumps

($50 to $200) can be expected to wear out after 10 to 20 years, as in any

hot-water system. Modern controllers ($100 to $200) have a mean lifetime of

at least 20 years.

As with drain-back systems, antifreeze systems are subject to scaling

only on the potable-water side, but require maintenance and occasional

replacement of tanks, pumps, and electronics. Antifreeze systems also

require replacement of the propylene glycol (because of breakdown of

corrosion inhibitors) every 5 to 10 years or more often if the system has

excess capacity and frequently maintains a high temperature.

Unglazed, low-temperature systems must be drained when the pool is closed

for the winter and when freezing temperatures are expected. The collectors

should last from 15-20 years. Vacuum relief valves and pressure relief

valves ($10 each) will require replacement every 5-15 and 10-20 years,

respectively.

Because parabolic-trough systems involve very-high-temperature and

-pressure fluid, they should be closely monitored. Operation and maintenance

is generally included as part of the contract for design and installation of

parabolic-trough systems. The mirror surfaces should be washed every few

months and will require replacement after about 15 years. Seals on the pumps

should be replaced every 10 years or so and the controls for the tracking

equipment may need replacing after anywhere from 10 to 30 years. But the

large pumps used for trough systems and the tracking equipment should last

for the life of the project.

(Back to Table of Contents)

Case Study—Chickasaw National Recreation Area

The Chickasaw National Recreation Area is located approximately 100 miles

south of Oklahoma City, Oklahoma. The National Park Service is planning

solar water-heating for one large and two small comfort stations. They

anticipate primarily summer use for all three buildings with very little

winter use. For the months of April through October, the average hot-water

load for each of the small comfort stations is projected to be 660 gallons

per day at a minimum temperature of 95°F (35°C); for the large comfort

station it is projected to be 1500 gallons per day at a minimum of 105°F

(41°C). There will be no back-up water-heating, so an important system

design criterion was how many hours during the use season the system would

not be able to meet these minimum temperatures.

The solar water-heating systems for each of the small comfort

stations will consist of 194 square feet of collector area on the roof and

500 gallons of preheat water storage in the mechanical room. Each of these

systems is expected to provide 32 MBtu (9394 kWh) of heat energy

annually—the total hot-water supply. Hourly simulations estimate that the

delivered water temperature will be less than the desired temperature of

95°F for 345 hours during the use season. The efficiency of the system in

converting solar radiation to heated water is estimated at 45% averaged over

the use season. Figure 12 shows solar energy incident on the array, energy

collected by the array, and annual total hot-water load for all 12 months

for a small comfort station. The estimated installed cost for each system is

$7,804. A cost breakdown is included in

Table 5. The calculated rate of return is 6.2% and the simple payback

period is 9 years. The life-cycle-cost estimate for the project developed

using the BLCC software is shown in Appendix D.

The solar water-heating system for the large comfort station will consist

of 482 square feet of collector area on the roof and 1000 gallons of preheat

water storage in the mechanical room. The estimated installed cost for the

system is $16,100. This system meets the use season load with the exception

of 579 hours. The rate of return is 5.9% and the simple payback period is 9

years. A summary of the characteristics of both systems is shown in Table 5.

A drain-back system is recommended for this application. Other system

types were considered but rejected for this particular application for the

following reasons:

- The high stagnation temperatures anticipated in wintertime would be

damaging to the fluids in an antifreeze system.

- Drain-down systems and recirculation systems both circulate potable

water through the collectors. The hard well water used at this site would

contribute to early obstruction of the small collector flow passages with

mineral deposits.

- Direct thermosiphon systems offer no freeze protection and indirect

thermosiphon systems offer no stagnation protection.

- Site considerations rule out ground-mounted tracking parabolic-trough

systems.

Aesthetics of the site are a primary consideration. Thus, only the

south-sloping roofs of the buildings were considered for siting solar

arrays. The shading effects of surrounding hills, trees, and buildings are

not of great concern because the solar heating system collects energy mostly

in the middle of the day and in summer, when the sun is overhead.

(Back to Table of Contents)

The Technology in Perspective

Despite problems with some 1980s installations, solar water-heating is a

proven technology that can play a significant role in reducing conventional

energy use at federal facilities throughout the country. There are a variety

of different types of solar water-heating systems available to match the

needs of different situations. Facilities dependent on high-cost water

heating are quite likely to find solar water-heating systems economically

attractive. Use for swimming pool heating is generally economical regardless

of conventional water-heating cost. Many facilities with large, constant

water use loads (prisons, hospitals and military barracks are frequently

good candidates) will find that large solar water-heating systems can be

designed to economically meet their needs. Even where the economic payoff is

small, such projects are of great value because of the added benefits of

reducing pollution and climate-change emissions by reducing fossil-fuel

combustion. (Federal facilities also need to comply with Executive Order

12902 and can play a valuable role by setting good renewable energy use

examples.)

The FEMP Federal Renewables Program at the National Renewable Energy

Laboratory can quickly assess whether solar water-heating is likely to be

economically attractive for a federal facility with a minimal amount of

information. Financial assistance beyond regular agency funding will likely

be very limited at least for the near future, but through the Energy Savings

Performance Contracting program of the Federal Energy Management Program,

agencies have the option of avoiding all installation costs and paying for

solar water-heating systems via utility savings bills.

The outlook for solar water-heating at federal facilities is excellent

from standpoints of technological feasibility, compatibility with existing

facilities, conventional energy use reduction, and pollution and

climate-change gas emission reduction. Solar water heating can be

effectively used at any facility that wants to make a commitment to using

it. For swimming pool heating, when competing against expensive water

heating, and where hot-water use is very large and consistent, there is a

good possibility of solar water heating being found economically attractive.

Technological breakthroughs to dramatically reduce costs and make solar

water heating economically attractive for other situations do not appear

imminent. Nonetheless, the situations where solar water heating has good

likelihood of being cost effective are substantial enough that the

as-yet-untapped potential for application at federal facilities is still

quite significant.

(Back to Table of

Contents)

Suppliers

Manufacturers of Collectors and Distributors of Systems

Certified by the Solar Rating and Certification Corporation |

American Solar Network, Ltd.

5840 Gibbons Dr.

Carmichael, CA 95608

(916) 481-7200

(916) 487-7225 Fax |

Heliodyne, Inc.

4910 Seaport Ave.

Richmond, CA 94804

(510) 237-9614

(510) 237-7018 Fax |

Nippon Electric Glass America, Inc.

626 Wilshire Blvd., Suite 711

Los Angeles, CA 90017

(213) 614-8667

(213) 623-2041 Fax |

Radco Products, Inc.

2877 Industrial Parkway

Santa Maria, CA 93455

(805) 928-1881

(805) 928-5587 Fax |

SOLMAX

3951 Development Dr., #11

Sacramento, CA 95838

(916) 924-1040

(916) 924-1098 Fax |

SunEarth, Inc.

4315 S. Santa Ana Street

Ontario, CA 91761

(909) 984-8737

(909) 988-0477 Fax |

Thermo-Dynamics, Ltd.

81 Thornhill Dr.

Dartmouth, Nova Scotia

Canada B3B 1R9

(902) 468-1001

(902) 468-1002 Fax |

|

| Collector Manufacture Only |

American Energy Technologies

P.O. Box 1865

Green Cove Springs, FL 32043

(904) 284-0552

(904) 284-0006 Fax |

Heliocol USA, Inc.

927 Fern St., Suite 200

Altamonte Springs, FL 32701

(407) 831-1941

(407) 831-1208 Fax |

Sunsiaray Solar Mfg., Inc.

7095 Schoolcraft

Davison, MI 48423

(810) 653-3502

(810) 744-4322 Fax |

Sun Trapper Solar

12118 Radium St.

San Antonio, TX 78216

(512) 341-2001

(512) 341-2652 Fax |

| System Distribution Only |

Heliotrope General, Inc.

3733 Kerora Dr.

Spring Valley, CA 91977

(800) 552-8838

(619) 460-9211 Fax |

Morley Manufacturing, Inc.

P.O. Box 1540

Cedar Ridge, CA 95924

(916) 477-6527

(916) 477-0194 Fax |

Solahart

155 Mata Way, Suite 109

San Marcos, CA 92069

(800) 233-7652

(619) 736-7023 Fax |

Sun, Wind & Fire Co.

7637 S.W. 33rd Ave.

Portland, OR 97219

(800) 397-9651

(503) 245-0414 Fax |

| Solar Energy Industries Association (SEIA)

Membership—Active Hot Water Systems: |

| American Energy Technologies, Inc. |

Green Cove Springs, FL |

(904) 284-0552 |

| American Solar Network, Ltd. |

Carmichael, CA |

(916) 481-7200 |

| BSAR Solar |

Solano Beach, CA |

(619) 259-8864 |

| Bio-Energy Corporation |

Kingston, NY |

(914) 336-7700 |

| Capitol Solar Service Company |

Castle Rock, CO |

(303) 792-0155 |

| Heliodyne, Inc |

Richmond, CA |

(510) 237-9614 |

| Industrial Solar Technology Corp. |

Golden, CO |

(303) 279-8108 |

| Metro Solar, Inc. |

Denver, CO |

(303) 782-9099 |

| Morley Manufacturing |

Cedar Ridge, CA |

(916) 477-6527 |

| Radco Products, Inc. |

Santa Maria, CA |

(805) 928-1881 |

| Solar Development, Inc. |

Riviera Beach, FL |

(407) 842-8935 |

| Sun Trapper Solar Systems, Inc. |

San Antonio, TX |

(210) 341-2001 |

| SunEarth, Inc. |

Ontario, CA |

(909) 984-8737 |

| SunSolar |

Bohemia, NY |

(516) 563-4900 |

| Sunquest |

Newton, NC |

(704) 465-6805 |

| Sunshine Plus |

West Babylon, NY |

(516) 789-9360 |

| Techno-Solis Inc. |

Clearwater, FL |

(813) 573-2881 |

| Thermal Conversion Technology |

Sarasota, FL |

(813) 953-2177 |

| SEIA Membership—Integrated Collector and Thermosiphon

Systems |

| American Energy Technologies, Inc. |

Green Cove Springs, FL |

(904) 284-0552 |

| Edwards Energy Systems |

Perth, Australia |

(619) 455-1999 |

| Hardie Energy Products Pty, Ltd/Solahart |

San Marcos, CA |

(800) 233-7652 |

| Mercury Solar |

Honolulu, HI |

(808) 373-2257 |

| Radco Products, Inc. |

Santa Maria, CA |

(805) 928-1881 |

| Solahart America |

San Marcos, CA |

(800) 233-7652 |

| SunEarth, Inc. |

Ontario, CA |

(909) 984-8737 |

| Sunshine Plus |

West Babylon, NY |

(516) 789-9360 |

| Thermal Conversion Technology |

Sarasota, FL |

(813) 953-2177 |

| SEIA Membership—Evacuated-Tube Systems |

| FAFCO, Incorporated |

Redwood City, CA |

(415) 363-2690 |

| Mercury Solar |

Honolulu, HI |

(808) 373-2257 |

| SunSolar |

Bohemia, NY |

(516) 563-4900 |

| Sunshine Plus |

West Babylon, NY |

(516) 789-9360 |

| Thermomax USA, Ltd. |

Columbia, MD |

(410) 997-0778 |

| SEIA Membership—Trough Systems |

| Energy Concepts Company |

Annapolis, MD |

(410) 266-6521 |

| Industrial Solar Technology Corp. |

Golden, CO |

(303) 279-8108 |

| Solar Kinetics/SOLOX |

Dallas, TX |

(214) 556-2376 |

| SEIA Membership—Swimming Pool Heating Systems |

| Aquatherm Industries, Inc. |

Lakewood, NJ |

(908) 905-9002 |

| Art of Solar, The |

Rancho Cucamonga, CA |

(909) 483-2495 |

| Bio-Energy Corporation |

Kingston, NY |

(914) 336-7700 |

| Capitol Solar Service Company |

Castle Rock, CO |

(303) 792-0155 |

| FAFCO, Incorporated |

Redwood City, CA |

(415) 363-2690 |

| Harter Industries, Inc. |

Holmdel, NJ |

(908) 566-7055 |

| Heliocol USA Inc. |

Altamonte Springs, FL |

(407) 831-1941 |

| Heliodyne, Inc. |

Richmond, CA |

(510) 237-9614 |

| Industrial Solar Technology Corp. |

Golden, CO |

(303) 279-8108 |

| Metro Solar, Inc. |

Denver, CO |

(303) 782-9099 |

| Morley Manufacturing |

Cedar Ridge, CA |

(916) 477-6527 |

| Radco Products, Inc. |

Santa Maria, CA |

(805) 928-1881 |

| Sealed Air Corporation |

Hayward, CA |

(800) 451-6620 |

| Solahart America |

San Marcos, CA |

(800) 233-7652 |

| Sun Trapper Solar Systems, Inc. |

San Antonio, TX |

(210) 341-2001 |

| SunEarth, Inc. |

Ontario, CA |

(909) 984-8737 |

| SunSolar |

Bohemia, NY |

(516) 563-4900 |

| Sunquest |

Newton, NC |

(704) 465-6805 |

| Sunshine Plus |

West Babylon, NY |

(516) 789-9360 |

| Techno-Solis Inc. |

Clearwater, FL |